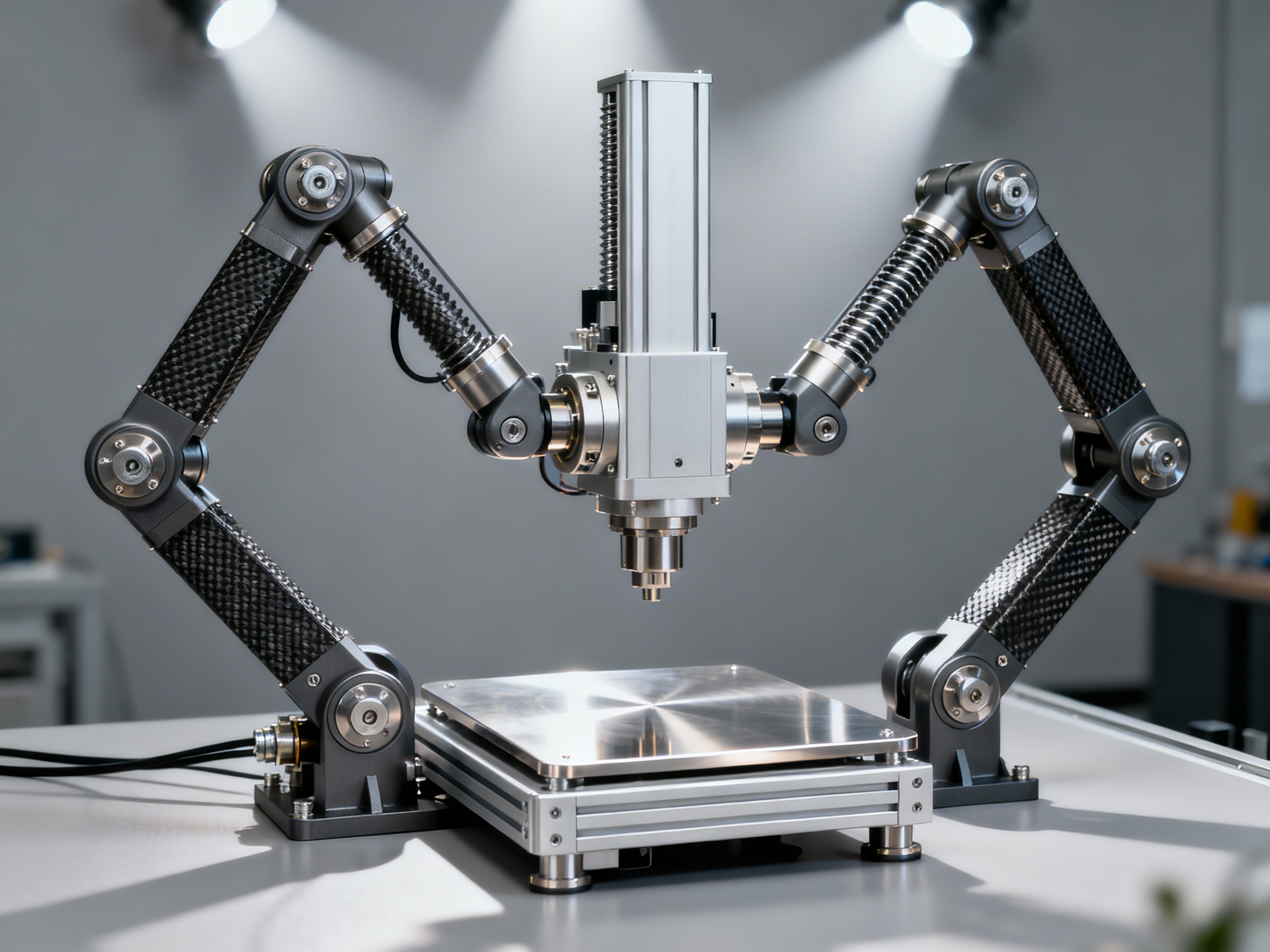

Open Source Delta Robot

Learning Platform

Complete Software & Hardware Reference Design | 100% Open Source

Perfect for experiments, learning, and research projects

Complete Solution

Hardware + Software + Docs

100% Open Source

No vendor lock-in

Ready to Experiment

Pre-tested reference design

All software and documentation are 100% free and open source. Hardware kit is optional to save time.