1. The best solar ball valve is one that combines durability, efficiency, and ease of use, with significant factors being: 1. Material composition enhancing longevity, 2. Design permitting higher flow rates, 3. Operating mechanism ensuring straightforward adjustments, 4. Compatibility with diverse systems. Among numerous options available, products crafted from high-quality PVC or brass often deliver superior performance. A detailed consideration of the specific application—like residential or commercial—is crucial; these selections should accommodate distinct pressure and temperature variations, emphasizing the significance of tailored solutions.

1. MATERIAL COMPOSITION

Choosing a suitable solar ball valve necessitates an understanding of material composition. PVC and brass are the two most prevalent materials; they each possess distinct characteristics essential for different applications.

PVC boasts remarkable resistance to corrosion, making it ideal for systems where chemicals might be present or for outdoor installations exposed to the elements. This versatility allows PVC valves to function well in various conditions. Additionally, PVC is lightweight, facilitating easier handling and installation. However, PVC might not withstand higher temperatures as effectively as its brass counterpart. For environments where temperature fluctuations are significant, brass emerges as a superior choice. Its robust structure can handle high pressures and temperatures, thereby enhancing reliability over time.

Moreover, the selection of materials directly impacts the longevity of the valve. For instance, a well-crafted brass valve, while potentially more expensive upfront, often translates to lower long-term costs due to fewer replacements and repairs. Careful consideration of the environmental factors surrounding the installation will significantly influence the decision regarding material choice.

2. DESIGN AND FLOW RATE

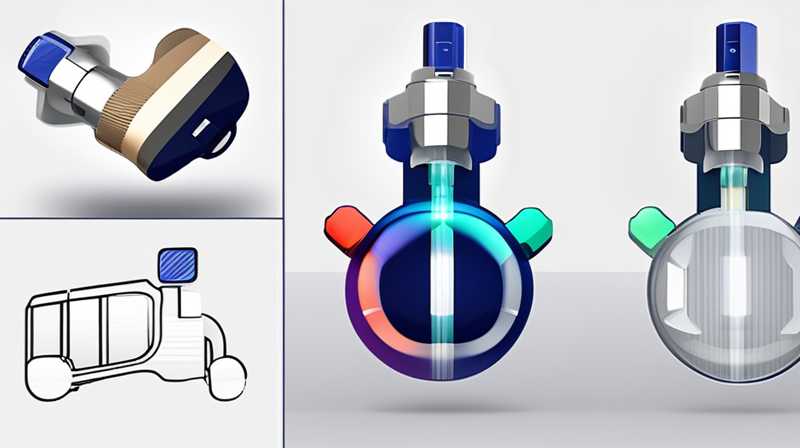

The design of a solar ball valve plays a pivotal role in its overall performance, particularly concerning flow rates. An efficient design minimizes turbulence and pressure drop, which can greatly enhance system performance.

The internal configuration of a valve affects how fluid moves. A straight-through design typically allows for higher flow rates compared to other configurations with bends or obstructions. This characteristic is crucial for applications where maintaining pressure and flow consistency is essential. In circumstances requiring rapid flow, opting for a valve with a smooth bore design can significantly influence the system’s operational efficiency.

In addition to the internal design, the size of the valve also affects flow capacity. A correctly sized valve matched to the size of the piping system ensures that flow is unimpeded. Oversized valves may lead to unnecessary energy expenditure, while undersized ones could cause bottlenecks. Proper sizing, thus, enhances overall system performance, correlating directly to energy efficiency and cost savings in the long run.

3. OPERATING MECHANISM

Another critical aspect of solar ball valves lies in their operating mechanism. Generally, there are two common styles: manual and automated. Manual valves require physical intervention to operate, which can be advantageous for simpler systems where adjustments are infrequent. Although user engagement is needed, manual valves generally have fewer components, which can reduce maintenance demands.

On the other hand, automated valves provide enhanced convenience, particularly in systems requiring frequent adjustments based on varying operational conditions. These valves can be programmed to respond to pressure changes, temperature fluctuations, or flow rate variations. Such automation significantly reduces human error and allows for optimally responsive fluid management.

However, the inclusion of automation introduces complexity. Components such as sensors and electronic actuators necessitate more significant initial investment and may require ongoing maintenance. Moreover, when selecting automated options, compatibility with other system components is crucial to avoid operational disruptions. Evaluating the specific needs of the installation will assist in determining the most appropriate operating mechanism, ultimately contributing to system efficiency and reliability.

4. COMPATIBILITY WITH SYSTEMS

Compatibility with existing systems is paramount when selecting a solar ball valve. Factors such as pressure ratings, temperature tolerances, and pipe dimensions must align with the valve specifications to ensure optimal functionality.

Many valves come with specific pressure and temperature ratings, which dictate their operational limits. When integrating a solar ball valve into a new or existing system, confirming that the valve can withstand the operational range of the system is essential. For instance, if a valve is utilized in an environment where pressure spikes are common, it should be capable of handling such fluctuations without failing.

Furthermore, the integration into piping systems should be seamless. Valves must be compatible with the diameter and material of the pipes in use. This is particularly significant in larger systems where mismatched components can lead to leakage or other performance issues. Therefore, thorough evaluation of compatibility before purchasing can prevent costly retrofitting or system malfunctions. Focusing on the long-term operational harmony of all components will ultimately ensure a well-functioning system.

5. ECONOMIC CONSIDERATIONS

Economic efficiency is often a decisive factor in the selection of solar ball valves. The initial purchase price might be a predominant consideration; however, long-term operational costs must also be evaluated.

High-quality valves, while initially more expensive, can reduce maintenance and replacement costs over time, thus proving more economical in the overall lifespan of the product. Valves that provide enhanced durability and resistance to wear will require fewer replacements, translating into cost savings. Moreover, energy efficiency is another economic aspect to assess. Incorporating valves that improve flow rates can lead to lower energy consumption, contributing to reduced utility bills.

Careful consideration of the total cost of ownership, which includes purchase price, installation expenditures, maintenance costs, and operational efficiency, will enable better decision-making. Evaluating these aspects ensures that the chosen valve not only fits the immediate budget but also aligns with long-term financial planning.

6. ENVIRONMENTAL IMPACT

The environmental impact of solar ball valves cannot be overlooked. Many jurisdictions are increasingly emphasizing sustainability in building practices, which extends to networking systems involving fluid management.

Choosing materials that minimize ecological footprints—such as recycled materials or those with low-impact manufacturing processes—can enhance a valve’s sustainability profile. Additionally, automated valves contribute to conservation efforts. By maintaining optimal flow rates and reducing waste, these valves help prevent unnecessary water or fluid loss, aligning with environmental best practices.

Moreover, considering the potential for reuse and recyclability at the end of a valve’s lifecycle is critical in an era of sustainability. Opting for products that can be reused or recycled contributes to a circular economy and helps mitigate the environmental impact. Therefore, integrating eco-conscious policies into procurement strategies supports broader sustainability goals.

7. BRAND REPUTATION AND SUPPORT

The reputation of a manufacturer should be an integral part of selecting a solar ball valve. Brand reliability often correlates with product quality, service, and warranty options. Established manufacturers are likely to have gone through rigorous testing and refinement processes, instilling confidence in the consumer.

Moreover, customer support plays a crucial role in long-term satisfaction. Manufacturers that offer knowledgeable support and resources help end-users navigate installation and operational concerns effectively. Strong post-purchase support can save time, prevent frustrations, and ensure that any potential issues are addressed promptly.

Evaluating reviews and feedback from other consumers can lend insight into the dependability of a brand. Engaging with knowledgeable suppliers who provide comprehensive product information can enhance the selection process and guarantee the best fit for the intended application.

8. MAINTENANCE REQUIREMENTS

Routine maintenance significantly affects the performance and longevity of solar ball valves. Understanding the specific maintenance needs of the product chosen is essential.

Regular inspections should be incorporated into operational practices to detect any signs of wear, leaks, or misalignment. The frequency of inspections will depend on the usage level and environmental conditions; high-use systems may require more frequent checks to ensure ongoing performance.

Additionally, cleaning the valve to remove buildup or debris will help maintain optimal functionality. Proper maintenance practices will not only prolong the lifespan of the valve itself but also contribute to the efficiency of the entire system. All components, including solar ball valves, require attention to retain their intended performance levels.

9. INNOVATIONS IN TECHNOLOGY

Recent advances in valve technology merit consideration during the decision-making process. Innovations such as smart valves, which integrate with monitoring systems, provide data analytics for improved water management. These technologies enable remote monitoring and adjustments based on real-time conditions.

Smart technology contributes to efficiency by optimizing valve performance according to current system demands, thereby minimizing waste and saving energy. As the technology landscape continues to evolve, integrating such innovations can provide additional layers of functionality and management.

Furthermore, technological advances encompass improved materials and manufacturing processes, leading to enhanced valve designs that are lighter, stronger, and more resistant to environmental stressors. Keeping abreast of such developments will enable decision-makers to select options that provide the best return on investment.

10. CONSIDERING INSTALLATION

Installation methods can impact the choice of a solar ball valve significantly. It is essential to assess whether the installation will be undertaken by professionals or as a DIY project. Each route will influence the type of valve selected.

For DIY installation, choosing user-friendly valves can ease the process, allowing for straightforward attachment and operation without requiring specialized knowledge. Conversely, if professionals will manage the installation, more complex valves with advanced features may be appropriate, assuming those professionals are trained to handle them.

Furthermore, checking for installation guidelines provided by manufacturers can furnish additional insight. Some products may include instructional videos or manuals that support the installation process. Consulting these resources can empower stakeholders to make informed selections that simplify installation and future maintenance.

Frequently Asked Questions

WHAT MAKES A SOLAR BALL VALVE STAND OUT?

A solar ball valve stands out based on various features, including its source material, design efficiency, and compatibility with different systems. The sourcing material influences durability, while design efficiency informs flow rates and operational ease. Valves designed for higher flow and lower-pressure drops will help maintain optimal performance in fluid movement systems. Yet, it is crucial that users assess compatibility with existing piping systems, ensuring that the distances and pressure specifications align suitably. Beyond technical specifications, reputable manufacturers supplying comprehensive support also enhance a valve’s value proposition. Thus, a combination of superior materials, design features, and reliable support contributes to a solar ball valve’s distinction in the marketplace.

HOW OFTEN SHOULD SOLAR BALL VALVES BE MAINTAINED?

The frequency of maintenance for solar ball valves can vary based on several factors, including usage levels and environmental conditions. Generally, it is advisable to conduct inspections at least once every six months. However, in systems subjected to intensive use or harsh conditions, more frequent checks may be beneficial. During these inspections, users should look for signs of wear, leaks, or foreign material buildup, as these can signal impending failure. Maintenance practices should also include periodic cleaning to prevent clogs that may affect performance. Keeping a detailed log of maintenance activities can help anticipate when more extensive servicing might be required, thus ensuring that valves continue to operate efficiently and effectively over the long term.

WHAT IS THE LIFESPAN OF A SOLAR BALL VALVE?

The lifespan of a solar ball valve typically ranges between 5 to 20 years, heavily dependent on the materials used, application conditions, and maintenance practices. Valves crafted from high-quality materials like brass or UV-resistant PVC tend to last longer, particularly in environments with variable temperature and pressure. Conversely, lower-quality materials may deteriorate more rapidly, leading to premature failures. Regular maintenance directly influences longevity; valves that are inspected and serviced consistently will outperform those neglected over time. Ultimately, understanding the environmental factors and implementing appropriate care strategies can significantly prolong the useful life of a solar ball valve, providing substantial value to the investment made.

In summary, selecting the best solar ball valve necessitates a thorough evaluation of multiple factors, encompassing material composition, design attributes, and compatibility with systems. Ensuring that the valve fulfills the specific operational requirements and adheres to budgetary constraints will enhance overall efficiency and longevity. It is essential to consider both initial capital outlay and the potential for long-term operational savings when making a choice, as the right valve can ultimately lead to improved energy conservation and reduced operational costs. Additionally, factoring in environmental impacts and the manufacturer’s reliability will contribute to informed decisions that align with broader sustainability objectives. Fostering a holistic approach to selection and incorporating innovations as they arise will not only resolve current needs but also pave the way for future adaptations. This foresight is crucial in cultivating robust fluid management systems that meet contemporary demands while supporting long-term resource sustainability. Therefore, investing in high-quality solar ball valves is pivotal for those seeking optimal performance and efficiency in fluid control applications.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-the-best-solar-ball-valve/