1. Various liquids and materials can be placed in a storage tank, including water, fuel, and chemicals. The selection largely depends on material compatibility, safety requirements, and environmental considerations. Storage tanks serve crucial roles in industries such as agriculture, construction, and manufacturing, enabling efficient material handling.

1. MATERIALS COMMONLY STORED IN TANKS

Storage tanks are versatile repositories that accommodate a wide variety of substances. The specific contents of these tanks largely hinge upon industrial applications and regulatory compliance. The three primary categories of materials typically housed in storage tanks include:

- Liquids: This category encompasses water, chemicals, petroleum products, and foodgrade substances, each necessitating distinct tank specifications. Water storage tanks are ubiquitous, serving municipal, agricultural, and industrial needs. Chemicals require storage tanks made from materials resistant to corrosion and chemical reactions. Tanks housing petroleum products or fuels demand strict adherence to safety standards to prevent contamination and ensure environmental protection.

- Gases: While predominantly regarded for liquid storage, tanks can also be adapted for gaseous substances. This includes pressurized gas such as propane or natural gas, requiring robust structural integrity and safety mechanisms for pressure relief and leak detection. Gas storage tanks are often equipped with advanced technology to monitor pressure changes and ensure safe operating conditions.

-

Solids: Some tanks may also be configured for the storage of solid materials, like grains or pellets. These systems typically feature various openings and access points to facilitate loading and unloading while maintaining an organized flow of materials.

2. STORAGE TANK CONSTRUCTION AND MATERIALS

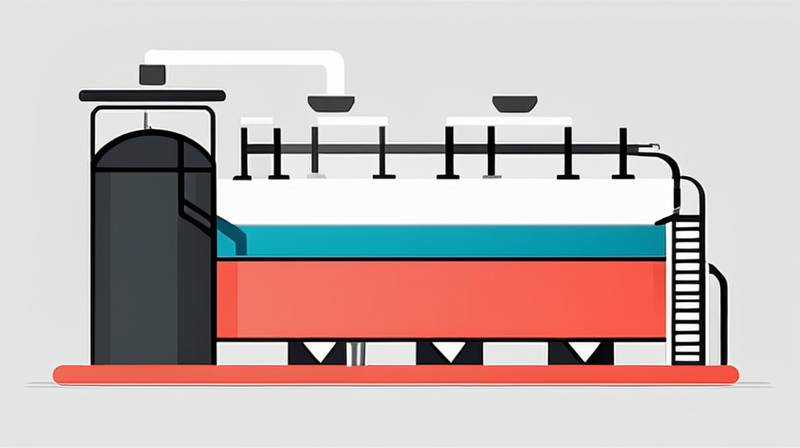

The design and materials used in storage tank construction play a critical role in determining their durability, safety, and suitability for the intended contents. Different tank types cater to the specific properties of the materials they house.

Vertical Tanks: Commonly utilized for liquid storage, vertical tanks can range from small capacity units to large structures holding thousands of gallons. They are typically constructed from steel or fiberglass reinforced plastic (FRP), chosen for strength, durability, and resistance to corrosion. The selection of material is crucial, especially for tanks storing corrosive liquids, which require linings and coatings that inhibit wear over time.

Horizontal Tanks: Used primarily for transporting liquids and storing substances on a larger scale, horizontal tanks sit on their sides and can be found both above and below ground. These tanks are particularly favored for their space-saving design. The construction materials for horizontal tanks generally mirror those used for vertical designs, yet their tolerance for weight distribution necessitates robust structural engineering.

3. REGULATIONS AND SAFETY CONSIDERATIONS

The placement of materials within storage tanks is heavily regulated to protect public health and the environment. Compliance with federal, state, and local regulations ensures safe operations and mitigates the risk of containment failure.

Environmental Regulations: Various agencies oversee environmental protections, dictating how substances are stored to prevent soil and water contamination. Storage tank operators must be familiar with the regulations concerning hazardous materials, spill prevention, and reporting procedures for leaks or ruptures. Proper documentation and adherence to guidelines on tank inspections significantly further compliance.

Safety Precautions: It is imperative to implement rigorous safety measures when using storage tanks, especially those containing flammable or toxic materials. Proper training for personnel managing tank operations is essential. Equipment such as automatic shut-off valves, level gauges, and overfill alarms should be installed, ensuring rapid response capabilities in case of incidents. Regular audits of safety systems help identify vulnerabilities.

4. INSTALLATION AND MAINTENANCE BEST PRACTICES

Proper installation and maintenance of storage tanks are paramount in ensuring the longevity of the structures and the safety of the materials contained. Both procedures demand meticulous attention to detail.

Installation Procedures: The initial installation of storage tanks should be preceded by thorough planning and site evaluation. This involves assessing soil conditions, proximity to utilities, and compliance with zoning laws. Engineers must evaluate the potential for seismic activity, particularly in areas prone to earthquakes, as this may affect long-term stability. Protective measures, such as berms or containment systems, provide additional safety against spills and leaks.

Routine Maintenance: Regular maintenance checks are essential in preserving the operational capacity of storage tanks. Inspections should focus on detecting corrosion, structural integrity, and signs of wear. Various methods such as ultrasonic testing, thickness gauging, and visual inspections ensure that tanks are in optimal condition. Implementing a routine protective coating application can extend the life of the tank and minimize corrosion.

5. EMERGENCY RESPONSE STRATEGIES

In instances of spillage or leaks, having a robust emergency response plan is critical. Preparedness allows for swift action to mitigate damage and protect public safety.

Contingency Planning: Operators are advised to create a detailed contingency plan that outlines specific procedures for responding to accidents involving storage tanks. This includes establishing communication protocols, coordination with local emergency services, and designating a response team trained in hazardous material handling.

Training: Continuous training sessions are necessary for all personnel involved in handling materials within storage tanks. Simulated drills help prepare staff for real-life scenarios, enabling them to react effectively and efficiently. Maintenance staff must be kept informed about changes in regulations or operational procedures to adapt to evolving standards.

6. COST FACTORS AND ECONOMIC IMPACT

The financial implications of utilizing storage tanks extend beyond initial installation costs. Long-term operational expenses and potential losses in case of accidents must also be considered.

Investment and Operational Costs: Significant funding is often required to purchase, install, and maintain storage tanks. Costs include construction materials, labor, monitoring equipment, regulatory compliance measures, and insurance. Operators must assess their budget carefully to account for potential fluctuations in costs associated with maintenance or regulatory updates.

Economic Consequences of Non-Compliance: Failure to adhere to safety regulations can lead to severe economic consequences. Legal penalties, fines, and the cost associated with cleanup operations can far exceed initial savings from neglecting regulations. Furthermore, contamination events can damage brand integrity, resulting in long-term financial repercussions.

FAQs

WHAT TYPES OF LIQUIDS CAN I STORE IN A TANK?

The suitability of specific liquids for storage hinges on several factors, including their physical and chemical properties. Common liquids stored in tanks include water, gasoline, diesel, and various chemicals. Each category requires unique tank materials to prevent corrosion, leakage, and contamination. For instance, storing corrosive chemicals mandates the use of specialized tank coatings or materials like fiberglass or polyethylene, which offer enhanced resistance. Additionally, flammable liquids require tanks equipped with safety features, such as pressure relief valves and grounding mechanisms to mitigate fire hazards. Understanding the properties of the liquid to be stored, along with adhering to industry regulations, is crucial in making informed decisions regarding storage tank selection and design.

HOW DO I DETERMINE THE PROPER TANK SIZE FOR MY NEEDS?

Choosing the appropriate tank size hinges on several interrelated factors. First, evaluating the specific volume of the material intended for storage is essential, including expected usage rates and fluctuations in demand, which may necessitate a larger capacity. Understanding the tank’s purpose—whether it serves a temporary holding capacity or a long-term storage solution—affects size selection as well. Geographic considerations, such as available space and local zoning regulations, will influence what sizes can be accommodated. Additionally, observing industry standards and allowing for future growth or changes in regulations is critical in selecting a size that remains viable over time, thus preventing costly modifications or replacements down the road.

WHAT ARE THE COMMON MAINTENANCE REQUIREMENTS FOR STORAGE TANKS?

Maintenance protocols for storage tanks are fundamental in ensuring their longevity and functionality. Key practices include routine inspections to identify signs of corrosion, leaks, or structural weaknesses. This may involve visual assessments or employing technologies such as ultrasonic inspection to measure wall thickness and integrity. Cleaning tanks regularly is crucial to remove sediments, biofilms, or particulates that may accumulate in the tank. Additionally, tanks must undergo periodic preventative maintenance, which includes repairs or reinforcement of structural components, application of protective coatings, and verifying the functionality of safety mechanisms such as alarms or shut-off valves. By adhering to a consistent maintenance schedule, operators can significantly extend the operational life of their storage tanks and ensure compliance with regulatory requirements.

The storage tank landscape is intricate and multifaceted. To optimize operations and maintain safety, attention to regulatory compliance, construction quality, and rigorous maintenance practices is indispensable. With the diverse materials at play and the myriad applications for storage tanks, understanding the nuances surrounding their usage enhances operational efficiency and promotes environmental stewardship.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-can-i-put-in-a-storage-tank/