Redwood Materials’ battery materials facility in Nevada is a $3.5 billion disruptor

Tesla co-founder JB Straubel believes that Redwood Materials’ $3.5 billion battery materials facility has the potential to significantly impact the United States’ electric vehicle (EV) supply chain. As the automotive industry transitions to electric vehicles, the demand for battery materials is set to rise. Redwood aims to meet this growing need.

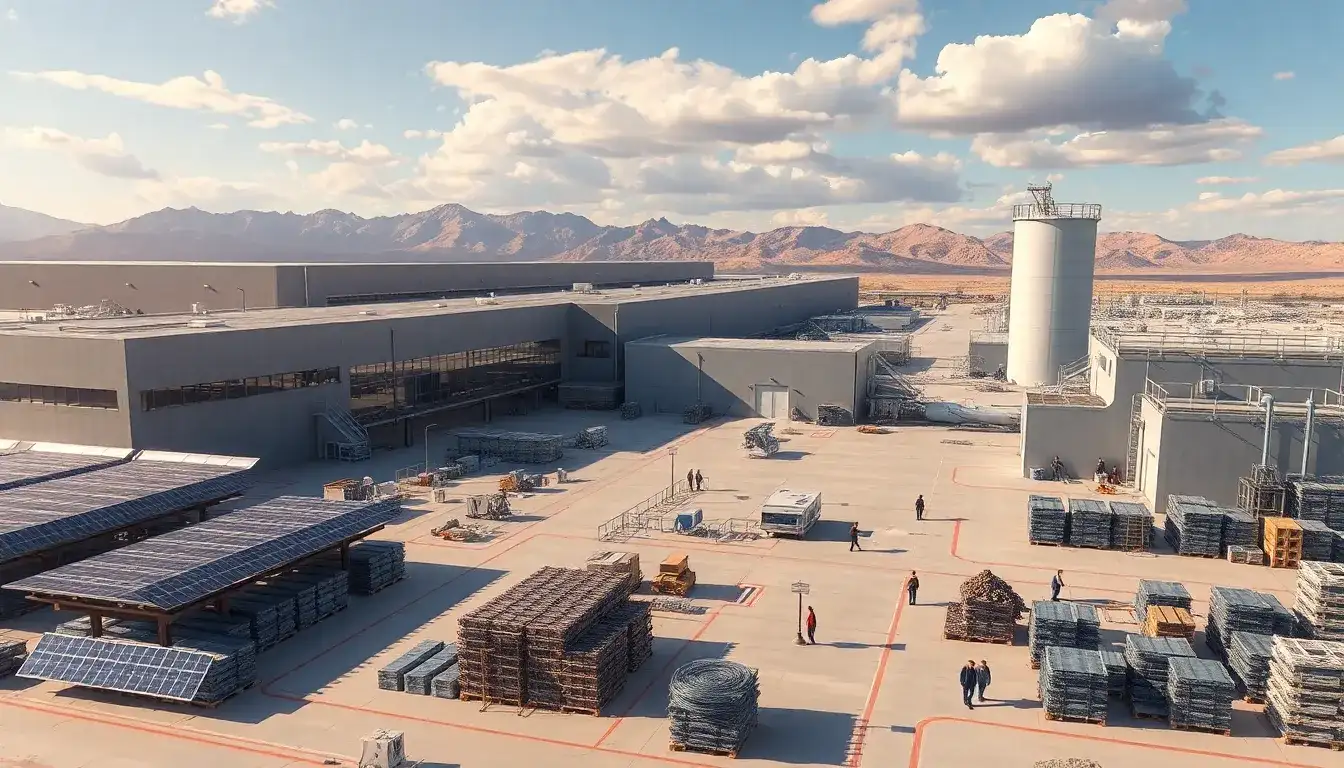

Located just outside Reno, Nevada, Redwood’s battery materials facility is currently under construction and is expected to be one of the first plants dedicated to producing critical components for battery cells from recycled batteries. This approach contrasts with other major battery manufacturers like SK Innovation Co. Ltd., which have primarily focused on investments in battery cell production in the United States. Historically, the U.S. has played a limited role in producing raw and intermediate materials for battery cells. As reported by The Wall Street Journal, even lithium sourced from the U.S. is often shipped to China or other Asian countries for processing before it can be used in battery cells. Redwood aims to change this dynamic by sourcing essential materials from recycled sources.

In a recent interview, Redwood Materials CEO JB Straubel highlighted the increasing demand for key battery materials. He noted, “Demand has skyrocketed, and now everyone’s building battery factories and EVs,” adding that the initial stages of the supply chain have struggled to keep up with this surge in demand. According to Benchmark Mineral Intelligence, China currently produces about 80% of the world’s cathode materials and over 90% of its anode materials, presenting a significant opportunity for companies like Redwood.

Once operational, Redwood’s $3.5 billion facility is anticipated to be extremely busy. The company is preparing to manufacture large quantities of the thin copper foil that forms the backbone of lithium-ion battery anodes. By 2025, Redwood expects to produce enough cathode materials and copper foil to support the production of one million electric vehicles annually. While this is an ambitious target, it still represents only a fraction of the batteries needed by automakers. JB Straubel anticipates that Redwood will be able to source over 30% of the lithium and nickel, and 100% of the cobalt required for its cathode materials through its operations.

In the meantime, Redwood’s customer base is expanding, with notable partners including Panasonic, which operates Giga Nevada in collaboration with Tesla, as well as other automakers like Volkswagen, Volvo, and Ford.

For further inquiries, feel free to reach out with news tips or messages to simon@teslarati.com.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/redwood-materials-3-5-billion-nevada-facility-set-to-transform-ev-battery-supply-chain/