To replace the valve core of a solar tube, you should follow these steps: 1. Identify the issue with the current valve core, 2. Gather appropriate tools, 3. Remove the existing valve core, 4. Install the new valve core, 5. Test for leaks. It is crucial to ensure that the system is de-pressurized before beginning any work to avoid unwanted accidents and ensure safety. In particular, meticulous attention should be paid during the removal of the old valve core; any debris or improper handling can damage the surrounding components. The installation of the new valve core should be executed with care, using the appropriate torque settings to ensure a secure fit.

1. UNDERSTANDING THE VALVE CORE’S FUNCTION

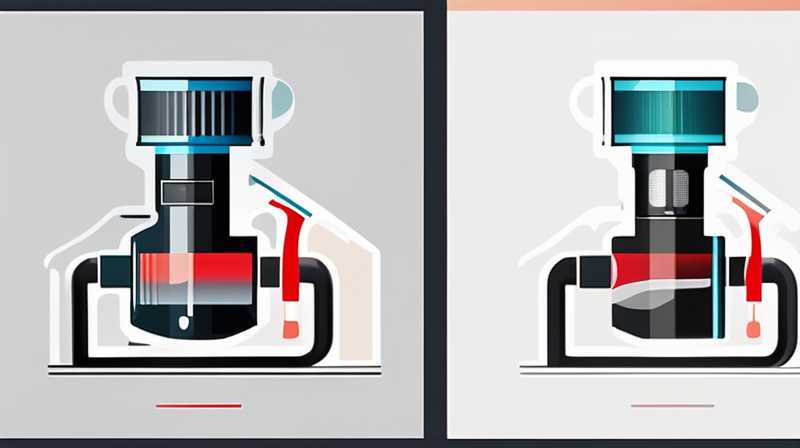

The valve core plays a pivotal role in the operation of solar tubes and serves a specific purpose within the system. Its chief responsibility is to control the flow of heat transfer fluid, thereby enabling efficient energy capture and heat exchange. Understanding this can help users appreciate the importance of maintaining or replacing this component when necessary.

The valve core is designed to regulate the pressure and facilitate the circulation of fluid within the solar tube. If malfunctions happen, such as leaks or blockages, the overall efficiency can decline, ultimately affecting the performance of the solar heating system. Thus, recognizing when it is time to intervene, and understanding what might be at stake can help in planning a timely replacement.

2. SIGNS THAT THE VALVE CORE NEEDS REPLACEMENT

Before undertaking replacement, recognizing the common signs indicating a valve core requires attention is vital. Some frequent symptoms include inconsistent temperature outputs, fluid leaks, or visible wear and tear around the valve area. Identifying these issues early on ensures that further damage can be avoided.

Temperature fluctuations can indicate that the valve core is not functioning optimally. If the heated fluid is unable to circulate properly, it can lead to cold spots within the solar system, negatively impacting the efficiency of energy absorption. On the other hand, if you observe leaks around the valve, it may point to the fact that the seal has deteriorated, directly compromising the integrity of the entire solar tube system. Ignoring such indications can lead to severe complications, making early intervention crucial.

3. PREPARING FOR THE REPLACEMENT

Before initiating the replacement process, ensure that proper tools and materials are assembled. Essential tools may include a wrench, silicone grease, and a new valve core, which must be compatible with your solar tube model. Preparing in advance not only facilitates a smoother process but also reduces downtime of the solar heating system.

Once the necessary materials are gathered, it’s prudent to follow strict safety practices. De-pressurizing the system ensures that there are no accidents during the replacement process. It is critical to consult the manufacturer’s instructions specific to your solar system to avoid any mishaps. Each solar tube might have unique features and requirements, thereby necessitating a careful approach tailored to its specifications.

4. REMOVING THE OLD VALVE CORE

Initiate the removal of the existing valve core with care. Using the appropriate tools, such as a wrench, loosen the valve’s connection meticulously to prevent damage to the surrounding components. Make sure the system has been de-pressurized for safety reasons. The removal process can sometimes be tricky, especially if the core has been in place for an extended period.

After successfully loosening the core, inspect it for any damages. Once removed, ensure that any remaining debris or old sealant is cleaned thoroughly. This preparation is vital for the seamless installation of the new valve core. Neglecting to clean the area can lead to inadequate sealing, causing potential leaks after installation. It is this attention to detail that ensures the longevity of the solar tube’s operation.

5. INSTALLING THE NEW VALVE CORE

With the old valve core removed and the area cleaned, it’s time to install the new core. Ensure to use compatible parts specifically designed for your solar tube model. It is advisable to apply a thin layer of silicone grease on the threads of the core to facilitate a secure fit and ease the installation process.

Complete the installation by carefully threading the new valve core into place. Ensure that it sits properly and use the wrench to tighten it accurately, adhering to the recommended torque settings. Over-tightening can damage both the valve and the surrounding components, while under-tightening could lead to leaks. Therefore, following precise installation instructions is crucial for optimal performance.

6. TESTING FOR EFFECTIVENESS

Post-installation, testing the effectiveness of the new valve core is essential. Begin by re-pressurizing the system carefully and observing for any signs of leaks around the newly installed core. This testing phase helps ensure that the system operates effectively without any unforeseen complications.

Monitor the temperature outputs for a reasonable period following the installation. Any inconsistencies may point toward improper installation or compatibility issues. In this case, seeking professional assistance might be necessary to rectify any problems that could arise from a faulty valve core.

7. MAINTAINING THE VALVE CORE

To prolong the lifespan of the valve core, proper maintenance practices should be adopted. Regularly checking the connection for leaks, monitoring system pressure, and ensuring the area around the valve remains clean will facilitate maintaining the efficiency of the solar tube. Scheduled inspections can catch issues before they escalate, thereby saving time and money in repairs.

It is also advisable to periodically review the manufacturer’s recommendations regarding maintenance schedules and best practices for care. Keeping accurate records of checks and replacements can aid in better decision-making regarding future upkeep. Engaging with professionals for routine maintenance can often uncover issues not visible to the untrained eye, ensuring sustainable performance.

FREQUENTLY ASKED QUESTIONS

WHAT TOOLS ARE NEEDED FOR VALVE CORE REPLACEMENT?

When preparing for the replacement of a valve core, having the right tools is paramount. Begin with a wrench, which will assist in loosening and tightening the valve connections. Additionally, silicone grease is recommended to ensure a secure seal when installing the new core. A cleaning rag or cloth is essential for maintaining the cleanliness of the workspace, ensuring all grime is eradicated before installation. Depending on the specific design of your solar tube, a few other specialized tools might be necessary, including a torque wrench or a pipe cutter. Always double-check the installation manual for exact specifications related to tool requirements.

Using these tools properly not only simplifies the procedure but also enhances safety during the replacement. For those who might feel apprehensive about executing such tasks, it can be beneficial to consult with or hire professionals, which ensures that the proper methodology is observed throughout the process. This safeguards against inadvertent accidents that could arise from improper handling.

HOW CAN I DETECT A FAULTY VALVE CORE?

Detecting a faulty valve core can typically be accomplished through careful observation and monitoring of the solar tube’s performance. Common signs include irregular temperature output, where the heated fluid fails to circulate properly, leading to cold spots in the system. Unexplained fluid leaks around the valve area may also indicate that the core has deteriorated, compromising its function.

It is advisable to monitor the pressure gauge on the solar system; if there are fluctuations outside normal ranges, this could signal an issue with the valve core. Performing periodic inspections can be beneficial for early detection of problems as well. Keeping a detailed log of observations can help track any changes over time and facilitate a proactive approach to maintenance and replacement as necessary.

HOW FREQUENTLY SHOULD I REPLACE THE VALVE CORE?

The frequency of valve core replacement can depend on various factors, including the quality of the initial installation, environmental conditions, and overall system usage. Generally, routine maintenance checks should occur at least once a year, which includes an assessment of the valve core’s condition. If indications such as leaks or performance drop-offs arise, immediate action should be taken to address the issue.

While some high-quality valve cores may last several seasons without issue, increased usage, or exposure to harsh environmental factors might accelerate wear and tear. Considering these nuances can inform a proactive schedule for replacement that keeps the solar system running efficiently and effectively.

In summary, replacing the valve core of a solar tube involves several critical steps that ensure optimal operation. The key steps include identifying the need for replacement, preparing for the task, removing the old core, installing the new core, and conducting effectiveness tests. Success hinges on careful execution and adequate preparation. Regular maintenance is crucial in prolonging the life of the valve core and the entire system. Addressing issues early can yield significant benefits and prevent costly repairs in the long run. Engaging with professionals for installation and maintenance can provide peace of mind, ensuring that the solar tube operates at peak efficiency. Proper education on the system and regular assessments can foster a more sustainable and long-lasting solar setup.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-replace-the-valve-core-of-solar-tube/