A comprehensive approach to repairing a solar conversion valve spool involves several critical steps and considerations. 1. Understand the mechanism of the solar conversion valve, 2. Identify specific issues that may arise with the spool, 3. Gather the appropriate tools and replacement parts, 4. Follow systematic procedures for disassembly, repair, and reassembly. A detailed examination of the valve’s inner workings is essential; it helps in diagnosing the exact origin of the malfunction. Problems frequently include wear and tear, improper sealing, or blockages that impede function, necessitating careful disassembly and evaluation. Regular inspections and maintenance are recommended to prolong the lifespan of these components.

1. UNDERSTANDING THE SOLAR CONVERSION VALVE

Solar conversion valves play a pivotal role in directing hydraulic flow within solar thermal systems. These devices ensure that heat transfer fluids circulate efficiently through collectors, storage tanks, and other essential components. One of the primary functions of the solar conversion valve is to maintain optimal temperature gradients, enabling efficient energy capture and transfer.

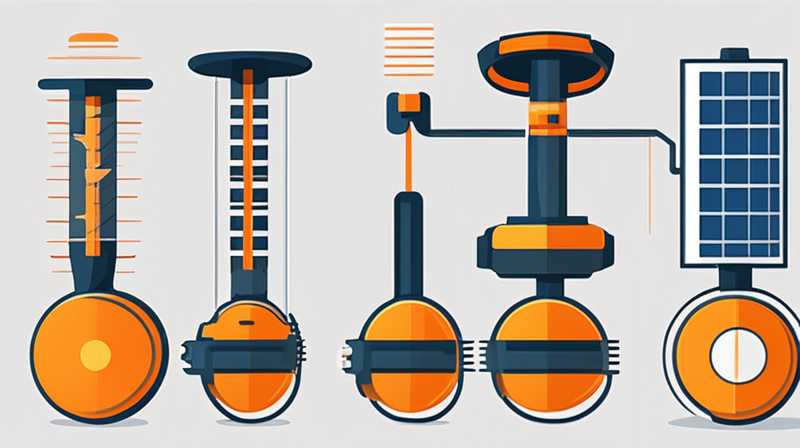

The valve consists of multiple parts, including the spool itself, which serves as the primary control element. The spool’s position dictates the flow path of the heated fluid, thereby affecting the system’s overall efficiency and effectiveness. A malfunction at this stage can lead to system inefficiencies, potentially resulting in energy loss and increased operational costs.

Moreover, understanding how the valve interacts with surrounding components is crucial for diagnosing issues. The relationship between the valve, pump, and heat exchangers is intricate; thus, one should assess the operation of these interconnected elements. Any irregularities in performance or flow rate could signal problems not only with the valve but also with the overall setup.

2. COMMON ISSUES WITH SOLAR VALVE SPOOLS

Delving into typical problems encountered with solar conversion valve spools reveals a range of potential issues. Leakage, poor sealing, and mechanical wear are among the most prevalent problems. Over time, wear and tear can compromise the integrity of the spool, leading to ineffective sealing and fluid leaks that detrimentally affect system pressure.

Leakage is often the first indicator that something is amiss within the valve. It can manifest as visible drips or a noticeable decrease in fluid levels over time. Identifying the source of leaks typically involves examining the spool and its surrounding seals. If the spool does not seat properly against the valve body, it will allow fluid to escape, necessitating repairs or replacements.

In addition, environmental factors such as temperature fluctuations and exposure to UV radiation can exacerbate wear on the spool. Prolonged exposure can contribute to the degradation of both the spool and seals, necessitating timely intervention to prevent further damage. Regular inspections and proactive maintenance must be adopted to mitigate these issues before they escalate.

3. GATHERING TOOLS AND REPLACEMENT PARTS

Before embarking on the repair journey, ensuring that all necessary tools and supplies are readily available is crucial. Essential tools typically include wrenches, screwdrivers, pliers, and a torque wrench for accurate adjustments. Having these at hand streamlines the process and minimizes delays during repairs.

In many instances, it is prudent to have replacement parts on standby, particularly the spool and associated seals. Sourcing high-quality components ensures longevity and effectiveness after repairs are completed. Compatibility with the existing solar system is vital; therefore, references to the manufacturer’s specifications or manuals will facilitate appropriate selections.

Moreover, safety gear should not be overlooked. Gloves and safety glasses protect against potential hazards associated with working on mechanical components. Creating a safe and organized workspace contributes greatly to the efficacy of the repair process. Evaluating and preparing one’s workspace in advance allows for a smooth workflow, reducing the risk of accidents or inefficiencies.

4. DISASSEMBLY PROCESS

Undertaking the disassembly of the solar conversion valve requires a methodical approach to ensure that all parts are handled with care. Begin by turning off any power sources and isolating the valve from the system to prevent any fluid movement. Draining the fluid from the system may also be necessary to avoid spills during the disassembly process.

After isolating the valve, meticulous attention should be paid to the configuration and order of parts as they are removed. Use labeled containers to store screws, washers, and other small components, which aids greatly in the reassembly phase. Documenting the configuration with photos serves as an additional reference, ensuring that nothing is overlooked during reinstallation.

Once the valve is fully disassembled, inspect each component for signs of wear or damage. The spool itself is particularly critical; paying close attention to its surface and sealing areas can unveil deeper issues that may necessitate further action. If degradation is evident, procuring a replacement spool should be prioritized before proceeding with reassembly.

5. REPAIRING OR REPLACING THE SPOOL

When it comes to addressing issues with the spool, there are two primary approaches: repairing the existing spool or opting for a complete replacement. Determining the most effective course of action is contingent upon the extent of the damage observed. Minimal wear or minor sealing issues may be resolvable through refurbishment techniques, while significant damage typically warrants a replacement.

If repair is chosen, clean the spool thoroughly to eliminate any debris or residue that may interfere with the sealing process. Replacement seals should be installed to enhance performance and prevent future leakage. Ensure that the spool is properly lubricated before reinstallation; this practice can significantly extend the life of the component and enhance its functionality.

In scenarios where a replacement is necessary, selecting a spool that matches specifications from the manufacturer is essential. Installing the new spool means reversing the disassembly process, paying close attention to ensure proper alignment and torque specifications as indicated in the service manual. A correctly installed new component will restore functionality and contribute towards overall system efficiency.

6. REASSEMBLY OF THE VALVE

Reassembly of the solar conversion valve involves reversing the disassembly steps while simultaneously ensuring that all aspects are addressed thoroughly. Start by carefully reinserting the repaired or replaced spool back into its designated position. Ensure that it seats properly against the valve body to prevent future leakage.

As you reinsert the remaining components, revisit documentation collected during disassembly. Confirm that each element is in its correct position and that all seals are intact. This meticulous approach will mitigate errors or omissions that could cause operational issues later.

After reassembling the valve, reconnect it to the system and refill any fluids that were drained during the process. Be sure to follow recommended guidelines for fluid types and quantities, as these will directly impact the system’s operational efficiency. Finally, conduct tests to verify that the valve is functioning as intended, checking for leaks and operational consistency.

7. TESTING AND MAINTENANCE

Following the successful reassembly of the solar conversion valve, conducting rigorous tests is imperative to ensure optimal performance. Testing involves checking the flow rates, temperature differentials, and overall operation of the valve as part of the solar heating system. This step not only assesses the success of the repair but also serves to confirm that no additional damage occurred during the repair process.

Monitor performance over time to confirm ongoing effectiveness. Regularly inspect the valve and surrounding components for signs of wear, leakage, or degradation. Scheduling periodic maintenance helps in promptly addressing potential issues before they escalate into significant problems, ensuring the longevity of the solar thermal system as a whole.

Implementing a detailed maintenance schedule, which encompasses regular inspections, cleaning, and adjustments, fosters a proactive approach to valve care. Maintaining proper fluid levels and ensuring that filters are clear enhances overall system efficiency. By incorporating these practices, users will maximize performance, energy efficiency, and lifespan of the solar conversion valve and its associated components.

FREQUENTLY ASKED QUESTIONS

HOW OFTEN SHOULD I INSPECT MY SOLAR CONVERSION VALVE?

Regular inspections of the solar conversion valve are crucial to ensure the efficient operation of the solar thermal system. It is advisable to schedule inspections at least twice a year, ideally in the spring and fall. During these inspections, technicians should check for signs of leakage, wear, and proper operation of the valve mechanism. Inspecting before and after peak solar energy usage seasons can help in identifying any potential issues before they impact system performance.

In addition, any time there are visible signs of malfunction, like decreased energy efficiency or noticeable leaks, an immediate inspection is warranted. Regular maintenance, including cleaning and lubricating moving components, can prevent wear and tear, enhancing the valve’s operational life. Keeping a maintenance log may also assist in tracking the condition of the valve over time, allowing for informed decisions about repairs or replacements as necessary.

WHAT TYPES OF REPLACEMENT PARTS SHOULD I USE?

When considering replacement parts for the solar conversion valve spool, priority should be placed on sourcing components that are compatible with your specific valve model. Utilizing original equipment manufacturer (OEM) parts is highly recommended, as these maintain the quality and operational performance standards established by the manufacturer. OEM parts typically ensure that proper dimensions and specifications are matched, minimizing the risk of installation issues.

In some cases, users might opt for aftermarket components, which can be satisfactory if they meet the required specifications and quality standards. However, it is paramount to conduct thorough research and select reputable suppliers known for high-quality products. Warranty offerings and customer reviews can be guiding factors in confirming the viability of aftermarket options. Always consult the manufacturer’s guidelines or seek advice from qualified professionals when making decisions about replacement parts.

IS IT POSSIBLE TO REPAIR A VALVE MYSELF?

Self-repair of a solar conversion valve is certainly feasible, contingent on the individual’s experience and comfort level with mechanical tasks. For those familiar with plumbing or mechanical work, especially in a solar or heating system context, undertaking the repair can be a straightforward process. Properly equipped with the right tools, replacement parts, and a detailed understanding of the valve’s operation, many common issues can be addressed effectively.

However, caution is advised. Engaging in valve repairs without sufficient knowledge can lead to further complications or system inefficiencies. If facing significant wear or damage, or if measuring temperature and flow dynamics seems challenging, it may be prudent to consult with a professional. This step assures thorough repairs and optimal functionality. Taking the time to assess one’s skill level in conjunction with the valve’s complexity can guide the decision on whether to undertake the repair independently or seek professional assistance.

Maintenance and timely repairs are vital to the performance and longevity of a solar conversion valve spool. Engaging in proactive inspections and covering repair essentials such as sourcing appropriate parts and understanding valve mechanisms will yield significant benefits. Completing thorough disassembly, careful examination, and vigilant testing post-repair enhances system efficacy. Embracing a routine maintenance schedule helps ensure consistent performance, maximizing both energy efficiency and overall function. This approach fosters sustained energy savings and optimizes the efficiency of solar thermal systems, thereby underscoring the importance of diligence in caring for critical components like the conversion valve spool.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-repair-a-solar-conversion-valve-spool/