1. The process of installing a solar booster pump circuit can be achieved through a series of detailed steps. 1. Understand the components, 2. Gather necessary tools, 3. Install the solar panel, 4. Connect the pump are crucial elements to consider for effective installation. A comprehensive exploration of the components is vital as it includes the solar panel, the booster pump, circuitry, and various connectors. Each of these elements plays a significant role in ensuring the entire system operates optimally. For instance, the solar panel converts sunlight into electrical energy that drives the pump, while the booster pump elevates water pressure for various applications, such as irrigation or household use. Proper knowledge of each component aids in troubleshooting potential issues during installation.

1. UNDERSTANDING THE COMPONENTS OF A SOLAR BOOSTER PUMP CIRCUIT

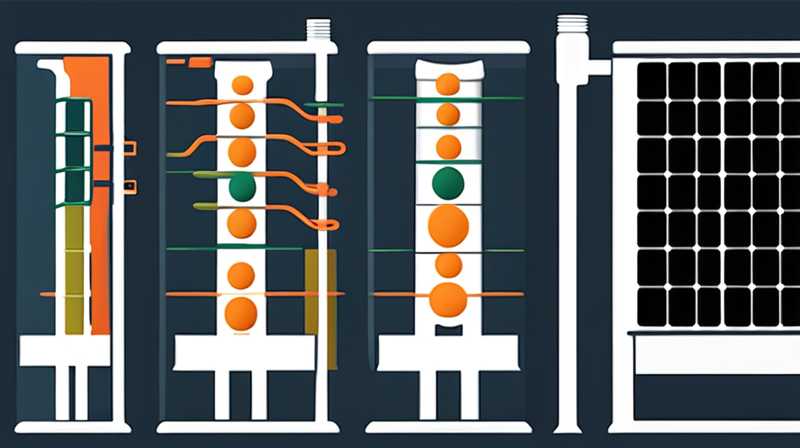

The installation of a solar booster pump circuit necessitates a comprehensive understanding of its components. Solar panels, booster pumps, charge controllers, and power inverters are critical parts of the system. Each component contributes uniquely to the entire configuration, and awareness of their functionality enhances overall effectiveness.

Solar panels harness solar energy, converting it into electrical energy. The photovoltaic cells within the panels work actively to ensure that adequate voltage is generated to power the connected devices. In this case, the operation of the booster pump relies heavily on consistent energy supply. Boosters pumps increase the water pressure necessary for effective distribution, making them indispensable in applications like irrigation.

Charge controllers regulate the amount of energy flowing from the solar panels to the batteries or directly to the pump. Proper installation ensures that the battery charge remains optimal and prevents overcharging, which can damage the system. Power inverters transform direct current (DC) from solar panels into alternating current (AC), if necessary, depending on the requirements of the pump type.

2. GATHERING NECESSARY TOOLS AND EQUIPMENT

Acquiring the appropriate tools and equipment is crucial for a successful installation of a solar booster pump circuit. Essential tools include wrenches, screwdrivers, electrical tape, and wire strippers. Additionally, having a multimeter is highly beneficial for electrical testing purposes. A careful selection of tools ensures that each step of the installation process is executed smoothly, minimizing the risk of mistakes.

When working with electrical systems, safety is paramount. Therefore, having safety gear such as gloves and goggles is advisable. Proper preparation involves gathering all tools beforehand to reduce downtime and enhance efficiency during installation. This methodical approach allows for a focused work environment that promotes careful attention to detail.

Furthermore, sourcing a reliable hybrid solar booster pump is integral to achieving a robust setup. These pumps are specifically engineered to operate efficiently with solar power, making them an excellent choice for this endeavor. Selection should consider performance ratings and energy efficiency, ensuring compatibility with the overall system requirements.

3. INSTALLING THE SOLAR PANEL

The next major step involves the installation of the solar panel. Proper positioning is critical to optimizing solar exposure, which directly influences the energy output. Selecting a location that receives unobstructed sunlight for the majority of the day is integral. The solar panel should be mounted at an angle that maximizes sun exposure, ideally between 30 and 45 degrees.

Once the location is determined, the mounting hardware should be installed securely to withstand environmental conditions. Whether it be on a roof or on a ground mount, ensuring that the solar panel remains stable is essential. This stability minimizes the chances of damage due to wind or other external factors. Special attention should be given during the tightening of screws; using a torque wrench may help achieve the appropriate tightness without damaging the panel.

After securing the panel to its mount, the next phase is to connect it to the booster pump circuit. This requires carefully running the cables from the solar panel to the charge controller or directly to the pump. Utilization of quality connectors is essential to prevent any loss of energy. Proper insulation may also be necessary to protect against weather-related damages that could compromise the system’s efficiency.

4. CONNECTING THE BOOSTER PUMP

The connection of the booster pump is a pivotal aspect of the installation process and requires meticulous attention to detail. The chosen pump should be compatible with the voltage output generated by the solar panel. This compatibility ensures that the booster can function without any interruptions, maintaining a steady flow of pressure to the water source.

To initiate the connection, the wiring must be executed with precision. Each wire type corresponds to either positive or negative connections, which should be clearly marked. This is crucial to prevent reverse polarity, which can inadvertently damage the pump or the solar circuitry. Wiring must be secured firmly but not overly tight, allowing for potential expansion and contraction due to temperature fluctuations.

Testing the connections with a multimeter prior to powering on can potentially uncover any inconsistencies. Once verified, the booster pump can be powered up for operation. It’s also advisable to check the water flow rate after installation to confirm that the system is operating at an optimal level. A well-functioning solar booster pump will lead to efficient irrigation practices or water supply solutions.

5. FINAL CONFIGURATIONS AND TESTING

Once the primary installation is completed, conducting a series of tests is imperative to ensure everything operates as intended. The final configurations might include adjusting the pressure settings of the pump and fine-tuning the solar panel’s angle for maximal performance. One should take time to familiarize themselves with the parameters of the booster pump, as various settings may optimize it for different applications.

After final adjustments, the system should be monitored during a trial run. Checking for any leaks or irregularities in the water pressure helps confirm that everything is functioning harmoniously. The integrity of the entire setup hinges upon minor details, making ongoing observation during initial usage essential to ongoing reliability and performance.

Once a satisfactory test run is completed, proper maintenance guides can be reviewed and applied to ensure the longevity of the solar booster pump circuit. This phase includes routine checks on solar panels for cleanliness, as dirt or debris can substantially reduce efficiency. Maintaining the pump and electrical connections is crucial for sustained operation and preventing future complications.

FAQS

WHAT IS A SOLAR BOOSTER PUMP?

Solar booster pumps are specialized devices designed to use solar energy to enhance water pressure. These pumps convert sunlight into electrical energy through solar panels, power the pump, and subsequently increase the efficiency of water delivery systems. Notably, these pumps are beneficial in various applications including irrigation in agricultural settings, supplying water for residential use, as well as in water feature installations. The efficiency of these pumps can significantly enhance water flow rates, facilitating better management of water resources. A major advantage resides in their sustainability; they harness renewable energy, thereby lowering operational costs and reducing carbon emissions.

HOW DO I CHOOSE THE RIGHT BOOSTER PUMP?

Selecting an appropriate booster pump requires careful consideration of several factors including the desired flow rate, the total dynamic head (TDH), and the specific application requirements. It’s essential to identify the volume of water needed, which will determine the flow rate required from the pump. Equally paramount is understanding the total dynamic head, which is the combination of vertical lift and any friction losses within the system. This understanding helps in determining the necessary pressure ensuring the booster pump operates effectively. Furthermore, ensuring proper compatibility with existing systems and evaluating energy efficiency can lead to choosing a model that not only meets technical specifications but also promotes sustainability over time.

WHAT MAINTENANCE DOES A SOLAR BOOSTER PUMP REQUIRE?

Routine maintenance is essential for the effective performance of solar booster pumps. Regular inspections should be conducted to identify any visible signs of wear or mechanical failure. Key components, such as the solar panels, should be kept clean, as dirt can obstruct sunlight, potentially reducing efficiency. Checking electrical connections periodically will help prevent operational failures that may stem from corroded or loose wires. Additionally, ensuring the booster pump is free of debris and that filters are cleaned frequently helps maintain optimal flow rates. Creating a maintenance schedule will facilitate planned inspections and keep the system running efficiently, thereby extending its operational lifespan and reducing the likelihood of unexpected breakdowns.

The effective installation of a solar booster pump circuit enhances water management through harnessing clean energy. This intricate process involves thorough knowledge of the components, proper tool selection, and precise connections to ensure efficiency and reliability. An effective configuration of solar panels and the booster pump culminates in sustainable solutions for both industrial and residential applications. Practicing routine maintenance and undergoing frequent checks can prolong the system’s lifespan while optimizing performance. Furthermore, sustainable energy practices, like utilizing solar energy, reduce ecological footprints, aiding global efforts toward environmental conservation. As water demand escalates globally, solar booster pumps present a proactive solution, not only addressing immediate water supply needs but also contributing positively toward a more sustainable future. Engaging professionals or seeking further education on installation and maintenance can provide a deeper understanding and ensure successful implementation. Clear documentation accompanies these systems, highlighting the specifications and guidelines necessary for optimum functionality.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-install-solar-booster-pump-circuit/