1. Difficulty in pressing the solar leather pad arises from several factors: 1, Material resistance, 2, Design complexity, 3, Resin application, 4, Heat sensitivity. Each of these aspects contributes to the overall challenge experienced when attempting to press such items, primarily due to the intricate balance required between pressure, heat, and timing throughout the process. Material resistance refers to how robust the layers of the leather and solar cells react under pressure, impacting the pressing effectiveness. The design complexity is essential, as solar leather pads often incorporate multiple layers and sensitive components that necessitate precise handling. Understanding these factors is crucial for anyone involved in the production or maintenance of solar leather pads.

1. MATERIAL RESISTANCE

Upon investigation, the characteristics of the materials utilized profoundly influence pressing efficacy. The solar leather pad incorporates several layers, typically composed of both synthetic and organic materials, imparting unique properties to the final product. The resistance of these materials to deformation under pressure is a primary obstacle.

Solar leather pads are often designed to withstand varying temperatures, which may inadvertently affect their responsiveness to applied forces during pressing. Materials such as polyvinyl acetate (PVA) or thermoplastic polyurethane (TPU) might exhibit substantial resistance, necessitating elevated temperatures or extended pressing durations to achieve desired outcomes.

Furthermore, maximizing the efficiency of the pressing process becomes critical, involving a well-calibrated approach to heat and pressure. When insufficient warmth is applied, the inherent stiffness within the materials presents a formidable barrier, complicating the pressing outcome. This necessitates designers and manufacturers to find an optimal balance that minimizes material resistance while preserving structural integrity.

2. DESIGN COMPLEXITY

Navigating through the multifaceted design aspects of solar leather pads can significantly contribute to raising the difficulty level when attempting to press them effectively. The intricate layering and integration of solar cells pose substantial challenges.

When examining these designs, it is crucial to consider the arrangement of various components. Incorporating solar cells alongside leather may involve delicate electrical connections, necessitating utmost precision during the pressing phase. A mismatch of layers or excessive pressure may jeopardize the electrical conductivity, leading to subpar performance or even complete product failure.

Furthermore, the variation in thickness across components hides subtleties within the pressing operation. Different sections may behave dissimilarly under pressure, causing uneven application of force throughout the pad. This discrepancy can lead to weak zones, which compromises the overall durability of the product. Manufacturers must meticulously engineer these designs, paying particular attention to how each layer will respond throughout pressing to mitigate potential failures.

3. RESIN APPLICATION

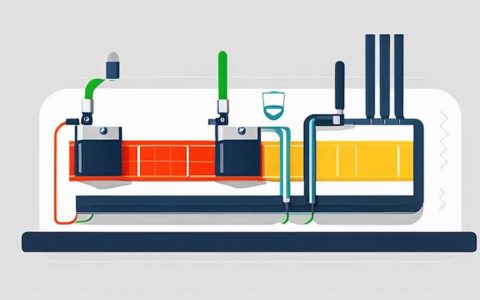

An essential aspect of solar leather pad development includes the application of resins and adhesives that bond the different materials together. The choice of resin can directly impact the pressing procedure. Incompatible resin types can harden under pressure, making it even more challenging to maintain a reliable bond between layers.

Certain types of adhesives require specific curing conditions, such as humidity or temperature ranges. For instance, applying excessive pressure may cause the resin to bubble or warp, compromising the integrity of the solar leather pad. This potential for degradation creates an additional layer of complexity during manufacturing.

Moreover, the timing of the resin application plays a crucial role. Ideally, the application should occur at a temperature that promotes adherence without exceeding the thermal limits of the solar cells or leather materials. This delicate balance becomes even more difficult during mass production, as achieving uniform application across numerous pads becomes a logistical challenge.

4. HEAT SENSITIVITY

When discussing pressing solar leather pads, it’s imperative to recognize the sensitivity of the materials to heat. Excessive heat can lead to deformation or even destruction of sensitive components, particularly solar cells. Each element within these pads is carefully calibrated for performance, making it crucial to control temperature variances meticulously.

Heat sensitivity dictates not only the pressing duration but also the required pressure levels. If the temperature exceeds the tolerance of particular components, they may yield unfavorable results, such as delamination or reduced efficiency. Design teams must factor in these potential heat-related complications early in the development process, ensuring that pressing parameters are tailored to safeguard each material’s properties.

Additionally, achieving uniform heat distribution during the pressing process stands as another significant concern. Hot spots may effectively deform certain areas while leaving others inadequately processed. Engaging with refined machinery capable of delivering consistent heat applications becomes essential. Ensuring that pressing systems are adequately calibrated to meet those specifications can dramatically enhance the success rate of producing solar leather pads.

FREQUENTLY ASKED QUESTIONS

WHAT IS A SOLAR LEATHER PAD?

A solar leather pad integrates solar technology into a flexible, leather-like material designed for various applications. This product harnesses solar energy through embedded photovoltaic cells, converting sunlight into usable power. The innovation primarily aims to provide a lightweight and aesthetically pleasing solution for energy generation, useful in contexts ranging from wearable technology to portable solar chargers.

The construction of such pads typically includes layers of leather or leather-like material bonded with synthetic substrates and solar cells. This layering process creates a functional yet stylish product, appealing to consumers and industries aiming to embrace renewable energy solutions without sacrificing design elements.

While their primary function revolves around energy collection, solar leather pads may also incorporate additional features, such as weather resistance or enhanced durability, making them suitable for outdoor and dynamic environments. Nevertheless, effective pressing of these pads remains a challenge, as discussed earlier.

HOW DOES PRESSING AFFECT THE PERFORMANCE OF SOLAR LEATHER PADS?

Pressing plays a vital role in determining the effectiveness of solar leather pads, influencing both structural integrity and operational functionality. Various factors come into play, including the distribution of pressure, the application of heat, and the material’s characteristics. A successful pressing operation encapsulates these critical elements and is aimed at optimizing the pads’ performance.

Should the pressing process be ineffective—whether due to inadequate temperature control, uneven pressure application, or incompatible materials—the resultant product may suffer from compromised efficiency. This may manifest in diminished energy output or shortened operational life for solar leather pads, ultimately impacting their practicality or market appeal.

In essence, ensuring that pressing aligns with the design goals is paramount to delivering a functional and reliable product. Manufacturers must conduct extensive testing and iterations throughout the development process to refine their methods and achieve the desired quality in pressing solar leather pads.

WHAT ARE THE BENEFITS AND LIMITATIONS OF USING SOLAR LEATHER PADS?

In evaluating solar leather pads, numerous benefits become apparent, alongside notable limitations that warrant consideration. One of the primary advantages includes the integration of renewable energy technology in a lightweight and versatile format. This distinct feature positions solar leather pads as attractive options for sustainable solutions in modern applications.

Moreover, the flexibility of this configuration allows for creative designs and innovative usage across multiple contexts. Their aesthetic appeal aligns well with consumer preferences, ensuring that renewable energy products can find a broader market reach without compromising style.

However, certain limitations also necessitate acknowledgment. Challenges faced during the pressing process, as previously highlighted, can diminish the effectiveness and reliability of solar leather pads. Temperature sensitivity and material compatibility require manufacturers to invest meticulously in developing methods that appropriately address these concerns.

Ultimately, navigating the balance between benefits and limitations becomes fundamental for the ongoing advancement of solar leather pads. Manufacturers must endeavor to innovate continually to enhance their products’ reliability and effectiveness while addressing pressing challenges.

Effective pressing of solar leather pads emerges as a multifaceted challenge requiring adept understanding and mastery of various factors. Engaging with material resistance, design complexity, resin application, and heat sensitivity allows for deeper insight into the difficulty associated with this process. Addressing these challenges will be pivotal in driving feasible innovations within the realm of renewable energy technology.

Manufacturers determined to elevate their production methodologies must focus on comprehensive testing and evaluation techniques that accommodate each aspect influencing pressing efficacy. Striking a balance among these considerations ensures that the end product maintains its integrity, functionality, and appeal within the competitive landscape.

As the demand for sustainable energy solutions continues to grow, so does the urgency to refine pressing techniques for solar leather pads. A commitment to enhancing manufacturing processes, leveling material challenges, and optimizing designs will solidify solar leather pads’ standing as a leading choice in renewable energy applications. The journey toward mastering pressing technology is not solely an academic pursuit but a critical pathway to advancing both technologies and eco-conscious consumer habits.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/why-is-it-difficult-to-press-the-solar-leather-pad/