1. The solar solenoid valve may become blocked due to various factors, including 1. inadequate maintenance, 2. the presence of debris or sediment, 3. pressure fluctuations, and 4. corrosion and wear over time. Among these reasons, the presence of debris or sediment is significant because it may accumulate within the valve or associated pipes, restricting fluid flow. This blockage can lead to malfunctions, inadequate system performance, and even permanent damage if not identified and rectified promptly.

1. UNDERSTANDING SOLAR SOLENOID VALVES

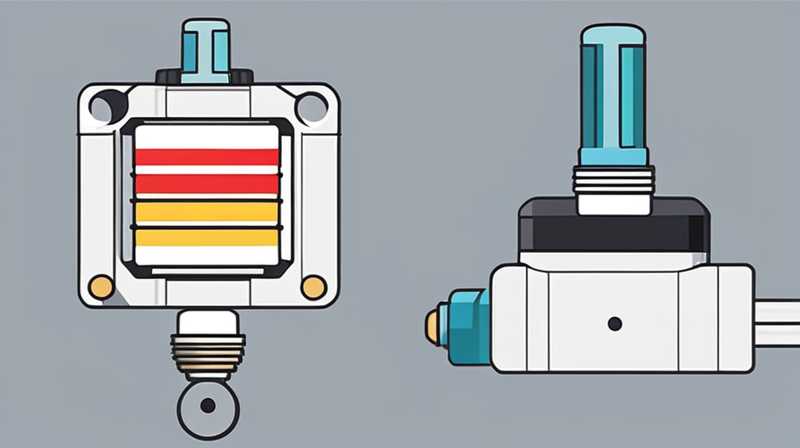

Solar solenoid valves function as critical components in a variety of solar energy systems, including those that manage the circulation of fluids for heating or cooling purposes. They are electromechanical devices, powered by an electric current which activates a coil to either open or close the valve. Understanding their functioning is essential to grasp how and why blockages occur.

A solar solenoid valve can control the flow of liquids, typically water or antifreeze solutions, and is integral in ensuring efficiency within the system. When these valves operate correctly, they help maintain proper flow to collectors or storage tanks, thereby optimizing the system’s overall efficiency. However, operational efficiency drastically decreases when blockages occur.

2. FACTORS CONTRIBUTING TO BLOCKAGES

2.1 INADEQUATE MAINTENANCE

One of the primary contributors to blockages in solar solenoid valves is insufficient maintenance routine. Regular checks are essential to ensure the components are functioning as intended, particularly in systems exposed to environmental factors such as dust, debris, and temperature fluctuations. Neglecting upkeep can lead to the accumulation of dirt and minerals within the valve, causing obstructions.

Furthermore, the lack of scheduled cleaning and inspection can result in the gradual build-up of scale and other contaminants, particularly in regions with hard water. Such scaling can restrict fluid passage and impair the valve’s operational efficiency. Implementing a consistent maintenance plan can significantly mitigate these issues, ultimately prolonging the life of the solenoid valve.

2.2 PRESENCE OF DEBRIS OR SEDIMENT

Another prominent reason for blockages is the presence of fine particles, debris, or sediment within the fluid being controlled. Over time, materials such as sand, rust, or organic matter may enter the system, particularly if filters are not in place or are malfunctioning. As these particulates flow through the system, they can accumulate at various junctions, especially within the valve itself, leading to significant flow obstruction.

Moreover, systems that involve water sourced from lakes, rivers, or other natural bodies can further exacerbate this issue due to the inherent impurities present in these water sources. Implementing pre-filters or sediment traps can help minimize the risk of particulate contamination infiltrating the solenoid valve, thus sustaining optimal performance and prolonging the system’s lifespan.

3. PRESSURE FLUCTUATIONS IN THE SYSTEM

3.1 IMPROPER PRESSURE SETTINGS

Pressure management within a solar thermal system is vital for ensuring the solenoid valve operates smoothly. Improperly set pressure levels can result in inconsistent flow rates, which can lead to turbulent conditions within the pipes, causing vibration and potentially dislodging sediment accumulated in the system. This turbulent activity can create varying levels of stress on the valve components, increasing the likelihood of blockage.

Additionally, over-pressurization can adversely affect the solenoid valve. It may force particulates into tiny gaps, allowing them to lodge within critical areas of the valve. Understanding the importance of fixture and pipe size, along with proper adjustment of pressure relief valves, is crucial for maintaining ideal operating conditions.

3.2 VIBRATION AND THERMAL EXPANSION

Systematic vibrations, as a result of rapid cycling or external mechanical influences, can lead to sediment shifting within the system. This mechanical movement may push accumulated debris into the solenoid valve, thereby increasing the likelihood of blockage. Not only do these vibrations dislodge particles, but they also cause thermal fluctuations that can help/hinder the valve performance, especially if they affect the sealing mechanisms in place.

Thermal expansion can also influence blockage conditions, particularly in systems exposed to varying temperature ranges. If a valve contracts and expands frequently, the gap between the mechanism components may also change, possibly allowing particles that wouldn’t normally fit to escape through to lodge themselves in awkward positions. Understanding the interplay between temperature, pressure, and mechanical dynamics is crucial for maintaining flow through the system.

4. CORROSION AND WEAR OVER TIME

4.1 MATERIAL DEGRADATION

Over extended periods, materials used in the construction of the solar solenoid valves may succumb to corrosion and wear. Various environmental and chemical factors can lead to deterioration, particularly in systems that utilize aggressive fluids or operate under harsh conditions. Corrosion can introduce flaking and particulate matter into the flow, exacerbating any existing blockage issues.

Replacing materials with more resistant materials, such as certain grades of stainless steel or PVC, can substantially improve resistance to corrosion. Moreover, frequently scheduled inspections can allow for early detection of wear, enabling proactive measures to be taken before the degradation leads to blockages or system failures.

4.2 IMPACT OF CHEMICALS

The chemistry of fluids utilized in solar thermal systems can also significantly impact the longevity of solenoid valves. For instance, the presence of certain chemicals may lead to chemical reactions resulting in the formation of precipitates that can accumulate over time within the valve, increasing blockage potential. Additionally, any corrosive properties of the fluids involved can catalyze material breakdown further exacerbating the issue.

Maintaining an appropriate chemical balance within the system is pivotal in preventing corrosive damage and subsequent blockages. Conducting regular water quality tests, especially in systems using non-purified water sources, can reveal potential chemical imbalances that may lead to corrosion. Employing chemical treatments can prevent corrosion, thus improving the longevity and functionality of solenoid valves.

5. PREVENTIVE MEASURES TO AVOID BLOCKAGES

5.1 REGULAR INSPECTIONS AND MAINTENANCE

Prioritizing regular inspections and a rigorous maintenance schedule are among the most effective strategies to mitigate blockages in solar solenoid valves. Establishing a routine allows for early detection of potential issues, such as sediment accumulation or material degradation. Prevention is always more efficient than remedial actions, therefore, ensuring valves function at their optimal capacity is crucial.

Moreover, technicians should be trained to recognize signs of deterioration or blockages during routine checks. This knowledge could facilitate swift rectification of any issues detected, preventing unnecessary downtime or extensive damage to the system. Implementing a preventative maintenance program can greatly enhance overall system reliability.

5.2 INSTALLATION OF FILTERS

Installing pre-filters or sediment traps at various points in the plumbing system can drastically reduce the likelihood of debris reaching the solenoid valves. Filters should be selected based on the specific requirements of the system, including the type of fluid used. Regular cleaning and replacement of filters are essential to ensure their effectiveness.

Investing in high-quality filtration systems can yield long-term benefits by reducing maintenance costs and avoiding costly repairs associated with solenoid valve blockages. Employing simple yet effective filtering mechanisms can dramatically improve flow rates and reduce the risk of compromising system integrity.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE COMMON SIGNS OF A BLOCKED SOLENOID VALVE?

Recognizing the early indicators of a blockage in a solar solenoid valve is pivotal for prompt intervention and preventing further complications. Some common symptoms to look for include inconsistent flow rates, where water may not achieve expected pressure or throughput, indicating that fluid circulation is impaired. Similarly, strange noises, such as rattling or vibrations while the valve is in operation, often hint at debris presence and abnormal flow patterns.

Additionally, observing leaks or dripping around the valve can indicate a malfunction, where improper sealing occurs due to blockage. If the valve fails to actuate properly, this may also lead to system shutdown or lack of desired operation. Regular monitoring helps detect these issues early, leading to quicker resolutions and minimal disruption.

HOW CAN I CLEAN A BLOCKED SOLENOID VALVE?

Cleaning a blocked solar solenoid valve requires a series of methodical steps to ensure thorough removal of the blockage without inflicting damage. Initially, the system must be unpressurized and isolated to prevent any accidents during maintenance. Disconnecting power to the solenoid is necessary to avoid inadvertent operation.

Subsequently, disassembling the valve component may reveal the obstruction, particularly if debris is lodged in the seat or orifice area. Using non-abrasive tools, such as soft brushes or cloths, can effectively remove build-up without scratching or damaging the components. After the cleaning, reassembling with care and ensuring all connections are secure is important. Conducting a final inspection for any remaining debris is crucial to guarantee optimal flow, followed by re-pressurizing and testing the system thoroughly.

WHAT MATERIALS ARE SOLENOID VALVES MADE OF?

When it comes to solenoid valves, the material selection is crucial for durability, compatibility, and efficiency under various operating conditions. Common materials used typically include brass, stainless steel, and thermoplastics. Brass is favored for its balance between strength and corrosion resistance, especially in applications involving water or non-corrosive fluids.

Stainless steel offers superior resistance to corrosion and can withstand harsh environments, making it suitable for aggressive chemicals or extreme temperatures. Conversely, thermoplastics may be employed in applications where weight considerations or cost are significant. Understanding the application and fluid compatibility informs the choice of valve materials, affecting performance and longevity.

SUSTAINED DISCUSSIONS ON SOLENOID VALVE BLOCKAGES

In essence, addressing the complexities surrounding blockage in solar solenoid valves requires a multifaceted analysis. Key considerations such as maintenance schedules, awareness of debris potential, and understanding pressure dynamics all play critical roles in ensuring the operational efficiency of these valves.

By focusing on preventive strategies and leveraging knowledge surrounding environmental and operational factors, stakeholders can dramatically reduce the likelihood of experiencing blockages. Empowering users with information about potential symptoms and signs of blockages fosters proactive responses, mitigating risks while ensuring seamless operations in solar systems.

Moreover, educational outreach regarding the influence of valve material and appropriate installation techniques aids in selecting components that sustain longevity and reliability. Advocating for stringent filter systems and prescriptive maintenance will further fortify systems against unexpected failures due to blockages.

Promoting a culture of continuous monitoring, vigilance, and effective communication among users will yield the desired success in maintaining solenoid valves. Keeping abreast of the potential issues surrounding solar solenoid valve blockages empowers parties involved to take informed actions. In this manner, not only is the efficiency of solar energy systems safeguarded, but environmental viability is equally respected, as clean energy harnessing remains an essential pursuit.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/why-does-the-solar-solenoid-valve-get-blocked/