1. The evaluation of different solar aluminum tubes leads to several noteworthy conclusions: 1) Material quality significantly influences performance, 2) The diameter affects energy absorption, 3) Coating type determines efficiency, and 4) Cost should always align with longevity. Each component plays a role in the overall effectiveness, but material quality stands out as a critical factor. Aluminums known for their strength and corrosion resistance often ensure longer-lasting and more efficient solar tubes.

1. MATERIAL QUALITY

The significance of material quality cannot be overstated when selecting solar aluminum tubes. It directly impacts the tube’s durability, resistance to environmental factors, and overall energy efficiency. High-quality aluminum with optimal alloy compositions offers superior strength while remaining lightweight. This combination fosters effectiveness in various weather conditions, particularly in regions prone to extreme temperatures or heavy precipitation.

Moreover, the manufacturing process employed can affect the fine balance between weight and sturdiness. Manufacturers utilizing advanced techniques produce solar tubes that minimize defects, ensuring uniformity in thickness and integrity throughout the structure. Specialized coatings applied during production can further enhance resistance to oxidation and corrosion, extending the lifespan of these tubes significantly.

2. DIAMETER SELECTION

The diameter of a solar aluminum tube holds considerable sway over its capacity to absorb sunlight and subsequently convert it into thermal energy. A larger diameter allows a greater surface area to capture solar radiation, which might be beneficial in specific installations, particularly in climates with extended sunlight exposure. Conversely, smaller diameters may yield advantages in situations where space is limited.

Selecting an appropriate diameter also interrelates with the intended application of the solar tube. For instance, residential systems may favor larger tubes to maximize energy production, while commercial enterprises might opt for compact designs that harmonize with their architectural aesthetics. Furthermore, the interplay between diameter and insulation properties is notable, as well. Adequate insulation enhances the efficiency of energy transfer by reducing heat loss, making careful diameter selection critical for optimal performance.

3. COATING TYPES

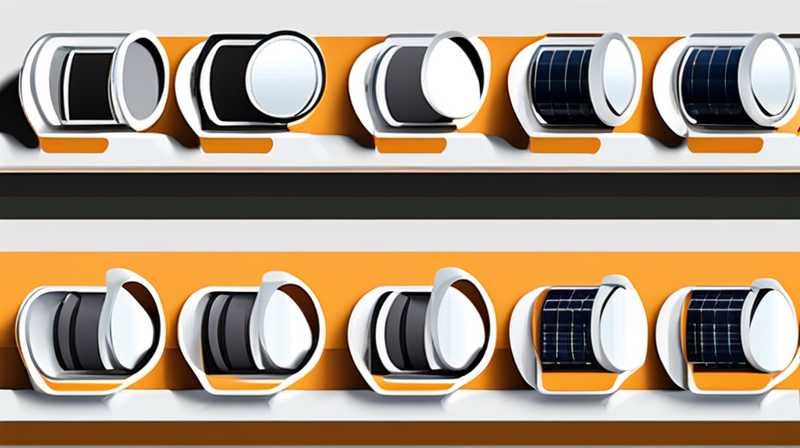

Coating types manifest crucial differences in efficiency and energy conversion. For instance, selective coatings are specifically designed to maximize absorption while minimizing re-radiation of thermal energy. These coatings often utilize advanced materials such as black nickel or copper-based compounds, which are highly effective at capturing solar radiation.

Understanding the characteristics of various coatings can also help in choosing the ideal solar aluminum tube for different environmental conditions. In sunny climates, tubes with superior absorption properties might significantly outperform others, while in overcast or cooler regions, considerations must shift to coatings that maintain high performance even under fluctuating conditions. Product longevity correlates tightly with the quality of the coating applied, sometimes even more so than the aluminum base material itself.

4. COST AND LONGEVITY

Economic factors play an integral role in decision-making. The relationship between cost and longevity needs careful consideration. While initial expenses may be a primary determining factor for many buyers, enduring savings derived from high-quality, durable products warrant thoughtful evaluation. Cheaper tubes might offer short-term affordability; however, they often incur higher maintenance costs or necessitate premature replacements, thereby negating initial savings.

Investing in quality solar aluminum tubes represents a long-term commitment to energy efficiency. By proactively addressing maintenance and replacement challenges, consumers can realize substantial financial benefits over time. The longevity of well-constructed tubes, alongside their efficiency contributions, can ultimately lead to a lower total cost of ownership and heightened return on investment.

FAQs

WHAT IS THE OPTIMAL MATERIAL FOR SOLAR ALUMINUM TUBES?

Selecting the best material for solar aluminum tubes often revolves around aluminum alloys known for strength and resistance to environmental degradation. Alloys like 6061 and 6063 are often preferred due to their excellent mechanical properties and corrosion resistance. These materials provide durability against weather extremes, ensuring longevity under expansive temperature fluctuations. Additionally, the production process plays a role; tubes manufactured using extrusion techniques can yield a more uniform and robust product.

Beyond mechanical properties, thermal conductivity also falls under consideration. Aluminum, by nature, has commendable thermal conductivity, allowing for efficient energy transfer. However, the coating applied to the aluminum is equally important, as high-quality coatings enhance energy absorption while reducing heat loss. In summary, a blend of high-quality aluminum alloy and sophisticated coatings ensures the best performance of solar aluminum tubes.

HOW DOES DIAMETER INFLUENCE ENERGY EFFICIENCY?

The diameter of solar aluminum tubes impacts energy absorption capabilities significantly. A larger diameter increases the surface area available for sunlight capture, enhancing potential energy output. This aspect becomes vital in sunny environments where maximizing solar collection is pertinent, as larger tubes can produce more thermal energy. However, tube diameter also influences other design factors, including installation space and potential heat loss characteristics.

Conversely, opting for smaller diameter tubes can result in savings on materials and space, making them suitable for applications where aesthetic considerations or physical space limitations are paramount. Each choice entails trade-offs between size, energy efficiency, and installation parameters, necessitating a thorough analysis based on specific project needs and environmental conditions.

WHAT IS THE IMPACT OF COATING ON SOLAR TUBES?

The coating applied to solar aluminum tubes dramatically influences their efficiency and performance. Selective coatings are particularly valued for their ability to absorb solar energy while reducing heat re-radiation, which significantly enhances overall efficiency. Coatings like black nickel offer high absorptivity levels, effectively capturing solar radiation to convert into thermal energy.

In colder climates, the right coating keeps heat loss at bay, ensuring that solar energy collected maintains its usefulness. The choice of coating determines not only energy efficiency but also the durability of the tubes. Quality coatings protect against corrosion and environmental degradation, preserving the tube’s integrity over time. This strategic selection between various types of coatings ultimately determines how effectively solar aluminum tubes perform in diverse conditions.

In summary, selecting the most effective solar aluminum tube entails meticulous evaluation across multiple attributes such as material quality, diameter, coating types, and extended cost versus longevity analysis. Each of these characteristics impacts performance and long-term efficiency goals, proving the importance of strategic decision-making in the solar energy sector. Moreover, continual innovation in manufacturing processes and material enhancements offers promise for the future of solar technologies. By closely examining these facets, consumers can ensure an informed investment in solar aluminum tubes that meet specific needs while maximizing energy yield. Strategic considerations pave the way for sustainable decisions that contribute positively to both personal and broader environmental outcomes, ensuring that renewable energy solutions remain accessible and efficient for future generations.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/which-solar-aluminum-tube-is-better/