To determine the appropriate pipe to which a solar pressure relief valve should connect, several factors must be considered. 1. The solar pressure relief valve typically connects to the outlet pipe, ensuring safety in the event of excess pressure. 2. It acts as a critical component in managing the temperature and pressure variations within a solar thermal system. 3. Proper installation is vital, as incorrect positioning can lead to system malfunction or reduced efficiency. 4. Consultation with local building codes and regulations is essential to ensure compliance.

1. UNDERSTANDING SOLAR THERMAL SYSTEMS

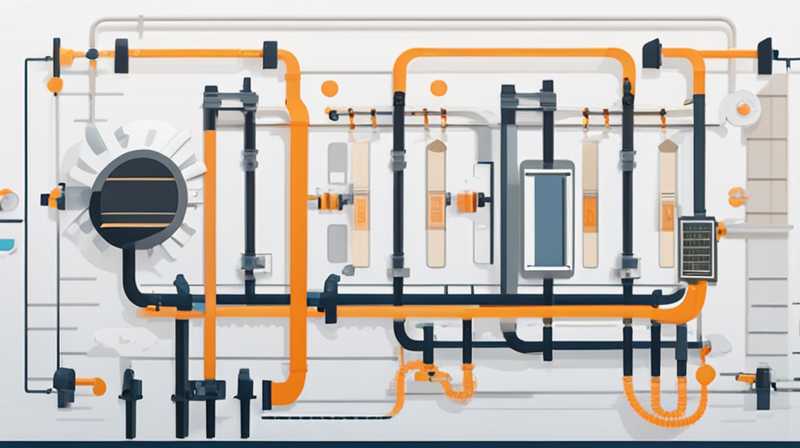

Solar thermal systems convert sunlight into heat, which can be used for various applications such as water heating and space heating. Within these systems, a solar pressure relief valve plays a pivotal role. By regulating pressure, it prevents potential damage to the system caused by thermal expansion or overpressure situations. This valve’s correct installation contributes significantly to the overall safety and efficiency of the solar thermal installation.

The choice of pipe for connecting the solar pressure relief valve involves several considerations. The material of the pipe must withstand high temperatures and pressures commonly found in solar thermal applications. Typically, a situation arises where copper or CPVC pipes are favored, and each type presents unique advantages. Copper pipes provide durability and thermal conductivity, while CPVC offers lighter weight and resistance to corrosion. Assessing the specifics of the system and local environmental considerations will guide the appropriate selection.

2. ROLE AND IMPORTANCE OF THE PRESSURE RELIEF VALVE

The pressure relief valve serves a critical function in safeguarding solar thermal systems from high pressure scenarios. 1. It activates during instances when the internal pressure surpasses safe limits, alleviating excess pressure by releasing hot fluid. 2. This preservation of system integrity mitigates damage to components such as collectors and piping.

Additionally, the response time of the valve is influential in maintaining optimal operation. A properly functioning valve must respond swiftly to changes in pressure, as slow activation can lead to dangerous conditions, potentially resulting in leaks or pipe burst scenarios. Consequently, ensuring the valve is correctly specified for the intended application is integral. This involves selecting a valve with an appropriate pressure rating and characteristics suited for the specific model of the solar thermal system.

3. CONNECTION OPTIONS FOR PRESSURE RELIEF VALVES

Connecting the solar pressure relief valve typically involves considerations around the outlet pipe and its configuration. Various options exist depending on the system design and layout, which may include direct connections to the collector or storage tank. In many cases, the ideal connection is made to the top outlet of the storage tank to effectively manage pressure buildup within the system.

When connecting the valve to the outlet pipe, proper orientation is crucial. Generally, the valve should be installed in a vertical position to allow for efficient flow and minimize the risk of blockage. Additionally, the proximity of the valve to the heat source should be assessed. The greater the distance from the heat source, the greater the risk of thermal expansion causing fluctuations in pressure.

4. REGULATIONS AND STANDARDS

Different regions have specific regulations and standards governing the installation of solar thermal systems, particularly where pressure relief valves are concerned. 1. Compliance with local building codes ensures the safety and viability of the installation. 2. Familiarization with applicable standards, such as those set by the International Plumbing Code or ASTM guidelines, is essential for contractors and system designers.

Understanding these regulations aids contractors in making informed decisions regarding the selection of materials and the appropriate configuration for the pressure relief valve. Failure to adhere to these standards can lead to serious legal and safety ramifications, so comprehensive research and possibly consultation with local building authorities should be considered before beginning any installation processes.

5. MAINTENANCE OF PRESSURE RELIEF VALVES

Maintaining the solar pressure relief valve is crucial for ensuring longevity and functionality. Regular inspections should focus on detecting signs of wear or malfunction, which can be indicated by leaks or reduced responsiveness during pressure fluctuations. If detection occurs, appropriate procedures must be taken to repair or replace the valve to avoid system failures.

Moreover, a schedule for routine maintenance can be beneficial in industrial and residential solar installations. Setting predetermined intervals for inspections can promote long-overlooked care and operational readiness of the valve and the entire system it protects, contributing to more reliable thermal performance.

FREQUENTLY ASKED QUESTIONS

WHAT IS THE FUNCTION OF A PRESSURE RELIEF VALVE IN SOLAR THERMAL SYSTEMS?

A pressure relief valve in solar thermal systems serves to protect the system from exceeding safe pressure limits. When the internal pressure surpasses a set threshold, typically due to thermal expansion during heating, the valve opens to release excess pressure either through a connected outlet or back into the system. This action helps prevent damage to pipes, tanks, and collectors, ensuring the longevity and operational integrity of the system. Proper functioning of the pressure relief valve plays a vital role in maintaining safety during temperature fluctuations, preventing dangerous situations that could lead to leaks or bursts. Regular examination and maintenance are recommended to ensure the valve operates effectively.

HOW DO I KNOW WHICH PIPE MATERIAL TO USE FOR MY PRESSURE RELIEF VALVE CONNECTION?

Choosing the right pipe material for connecting a pressure relief valve involves considering several factors including temperature and pressure stability. Common materials like copper and CPVC are widely accepted; while copper offers excellent thermal conductivity and durability, CPVC is favored for its resistance to corrosion and lower weight. Your selection should align with the specifications of the solar thermal system and local building codes, which may dictate certain material use. Additionally, assessing cost and installation ease can also help inform your decision. Consulting with a system designer or a licensed contractor can further offer insights that ensure the selected pipe material is safe and compliant with relevant standards.

WHAT ARE THE DANGERS OF INCORRECTLY INSTALLING A PRESSURE RELIEF VALVE?

Improper installation of a pressure relief valve can expose the solar thermal system to significant risks including system failure or damaging component rupture. If positioned incorrectly, the valve may not activate as intended during pressure spikes, leading to hazardous conditions such as leaks or explosions. Additionally, mistakes in orientation or distance from the heat source extend the potential for thermal expansion issues, potentially risking the entire installation’s integrity. Adherence to manufacturer specifications, professional installation guidelines, and local regulations is crucial in mitigating these dangers, ensuring that the pressure relief valve operates reliably and effectively throughout the lifespan of the solar thermal system.

SIGNIFICANT INSIGHTS INTO PRESSURE RELIEF VALVE CONNECTIONS

Installation of a solar pressure relief valve is a critical aspect of solar thermal systems that merits careful consideration to ensure safe and efficient operation. Each decision surrounding the selection of pipe materials, the valve’s placement, regulatory adherence, and maintenance practices directly impacts the long-term functionality of the system. Recognizing the importance of connecting the valve to the outlet pipe is essential, as it facilitates the management of pressure fluctuations resulting from thermal dynamics.

Furthermore, understanding the various materials available for connection, such as copper and CPVC, allows for the selection of the best option suited to specific environmental conditions of use. Thoroughly evaluating local codes and regulations is fundamental not only for compliance but also quality assurance of the installed system.

By maintaining a schedule for regular inspections, users can ensure the pressure relief valve continues to function optimally, thereby protecting against potential system failures and bolstering overall operational reliability. Investing in education and professional guidance when installing solar thermal systems emphasizes the importance of proper pressure management, ultimately extending system longevity and enhancing performance.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/which-pipe-should-the-solar-pressure-relief-valve-be-connected-to/