To determine the appropriate pipe for the installation of a solar solenoid valve, there are several key considerations to keep in mind. 1. Material selection is crucial, for instance, CPVC or PEX are preferred for their resistance to corrosion and UV degradation, 2. Diameter must be suitable to accommodate water flow without restriction, 3. Pressure rating should match or exceed the system requirements, and 4. Proper insulation is essential to prevent heat loss in solar applications. Among these, the choice of material deserves particular attention, as it directly influences the longevity and efficiency of the system. For example, CPVC is widely favored in solar applications due to its thermal resistance and lightweight properties, which make installation easier while ensuring durability.

ANALYSIS OF PIPE MATERIALS FOR SOLAR SOLENOID VALVES

1. MATERIAL INTEGRITY AND DURABILITY

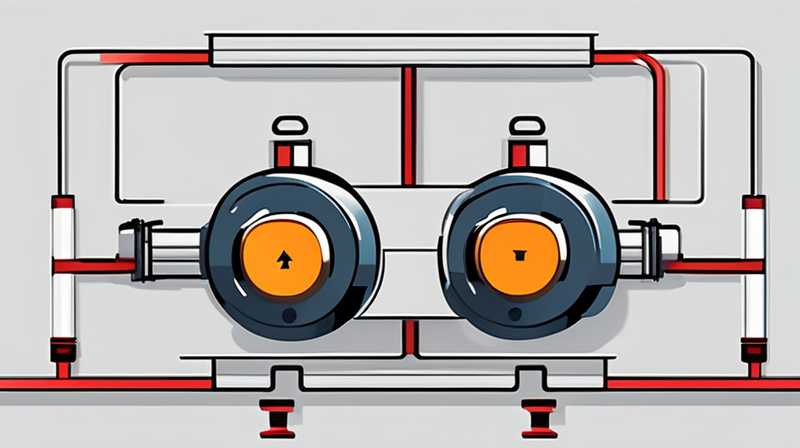

When it comes to selecting the appropriate pipe materials for solar solenoid valves, material integrity and durability stand out as paramount factors. A variety of materials are available, yet CPVC (Chlorinated Polyvinyl Chloride) and PEX (Cross-Linked Polyethylene) have consistently gained popularity among installers and engineers. CPVC pipes are particularly appreciated for their resistance to ultraviolet rays and hot water, rendering them ideal for solar applications where temperature fluctuations are commonplace. This material is lightweight, which simplifies the installation process, and it possesses a strong structural integrity that prevents leaks over extended periods. In comparison, PEX offers flexibility and ease of installation. This characteristic allows for quick changes in direction without requiring additional fittings, ultimately reducing potential points of failure.

Moreover, it’s critical to recognize the importance of thermal resistance, especially in solar applications. Pipes endure significant temperature variations from environmental heat and fluid movement through the system, leading to thermal expansion and contraction. Both CPVC and PEX can handle these temperature offsets, provided they are appropriately rated. Therefore, when assessing these materials, it is crucial to consider regions impacted by intense sun exposure. Installing materials resistant to UV radiation can prolong the life of the system and minimize maintenance efforts.

2. DIAMETER AND FLOW CHARACTERISTICS

The issue of pipe diameter is equally significant in the context of a solar solenoid valve installation. Determining the correct diameter is essential to ensure proper water flow and prevent pressure loss. While many installers prefer to use standard diameters such as two-inch or one-inch, the specific requirements of the system should dictate the selection. Small diameter pipes may lead to excessive pressure buildup, risking potential ruptures, while overly large pipes can reduce water velocity, leading to sediment accumulation and reduced efficiency over time.

Flow dynamics can drastically alter system performance, making it vital to conduct a thorough analysis of the water demand and solenoid valve specifications before finalizing pipe diameter. Hydraulic calculations and simulations may provide insight into various scenarios, allowing installers to preemptively address any potential flow-related issues. When examining diameter specifications, industry standards and manufacturer guidelines must be factored into the decision-making process, ensuring compatibility throughout the system.

3. PRESSURE RATINGS AND SYSTEM REQUIREMENTS

Pressure rating plays a foundational role in ensuring the efficacy and safety of the solar system. In most solar applications, pipes face high-pressure outputs, necessitating a thorough assessment of their pressure ratings. The chosen pipes should ideally handle pressures exceeding system demands to allow for pressure fluctuations, which are common in solar applications during fluctuating sunlight conditions or sudden valve actuation.

In addition to pressure ratings, one must also consider the temperature ratings provided by manufacturers. Solar systems often experience fluctuations in thermal energy, leading to increases in internal pressure. Thus, selecting pipes with higher pressure and temperature ratings guarantees the system’s robustness against unforeseen conditions. For instance, CPVC has a pressure rating of up to 400 psi at a maximum temperature of 200°F, making it well-suited for various solar configurations. PEX materials, on the other hand, also have commendable pressure ratings while offering flexibility adequate for dynamic installations.

4. INSULATION AND HEAT RETENTION

Insulation serves as a critical component in maintaining efficiency in solar installations, particularly concerning solenoid valves. Proper insulation techniques enhance heat retention, minimizing energy losses during water transportation. This characteristic is particularly vital in systems that utilize heated water for various applications. Insulating pipes can prevent heat loss, ensuring optimal performance by maintaining the desired temperatures when water travels from solar collectors to storage tanks or final delivery points.

Various insulation materials are suitable; however, selecting a combination that excels in thermal performance while withstanding environmental conditions is a complex decision. Closed-cell foam insulation is often preferred for its excellent thermal resistance and water repellency, minimizing moisture intrusion that can degrade pipe integrity. Additionally, reflective materials help maintain heat by shielding pipes from direct sunlight, further enhancing energy efficiency. The overall approach to insulation should emphasize not only thermal performance but also material longevity in outdoor installations.

5. REGULATORY COMPLIANCE AND STANDARDS

Navigating through the intricacies of regulatory compliance and applicable standards forms a significant part of pipe selection for solar solenoid valve installations. Adhering to relevant industry guidelines ensures not only the longevity and efficiency of the system but also aligns with safety protocols necessary for lawful installations. It is of paramount importance that the materials comply with local building codes, health standards, and certification requirements.

Additionally, installers should be aware of the distinctions among national and international standards. A comprehensive understanding of these regulations allows for the proactive identification of potential noise caused by pipe installation, facilitating necessary adjustments. Furthermore, proper certification guarantees that the materials pose no risk regarding toxic elements, which is crucial when piping water systems intended for human consumption or environmental discharge. Thus, consultation with regulatory bodies and continuous monitoring of updates in compliance requirements are essential practices.

6. THE ROLE OF PROFESSIONAL INSTALLATION

Ultimately, the process of selecting and installing pipes for solar solenoid valves should not solely rely on material and technical specifications; the expertise of professional installation cannot be discounted. Well-trained professionals bring valuable knowledge regarding installation techniques, potential pitfalls, and innovative solutions tailored to specific system needs. The installation phase can make or break the effectiveness of the entire solar system, highlighting the importance of engaging skilled technicians who understand the intricacies of solar technology.

Expert advice is particularly valuable during the design phase, where system deficiencies can be identified early on. Professionals can also provide insights into the latest advancements in pipe technology and installation techniques, ensuring that the solution implemented aligns with cutting-edge practices. Their experience helps mitigate common installation errors such as improper sealing, inadequate support, or misguided pipe routing, which can lead to leaks or system failures.

FREQUENTLY ASKED QUESTIONS

WHAT MATERIALS ARE PREFERRED FOR SOLAR SOLENOID VALVE PIPES?

When considering materials for solar solenoid valve pipes, CPVC and PEX are commonly favored due to their unique properties. CPVC stands out for its thermal resistance and durability against environmental elements, making it ideal for representing solar applications. On the other hand, PEX provides flexibility, allowing for easier installation, especially in intricate layouts. Both materials also possess high-pressure ratings, which are essential in ensuring the system functions effectively without risk of failure.

Moreover, alternative materials such as PVC may also find application, yet they often fall short in terms of thermal properties. The enduring nature, coupled with resistance to UV degradation, makes CPVC an unparalleled choice for longevity. In grass-root designs, considerations about local codes and regulations can further dictate suitable options, with some regions advocating for specific materials to comply with safety and sustainability measures.

HOW DOES PIPE DIAMETER AFFECT SYSTEM PERFORMANCE?

The diameter of pipes plays a pivotal role in determining system performance, most notably influencing factors such as flow rate, pressure maintenance, and overall efficiency. Choosing an inappropriate diameter can result in either constricted flow or excessive pressure drop, both of which hinder operational efficiency. Smaller pipes may lead to significant friction losses, while larger pipes could render water flow sluggish, increasing the time required for systems to respond actively.

Moreover, the selection process must consider the specific requirements of both the solar solenoid valve and the system it serves. It’s vital to conduct thorough hydraulic calculations to ascertain the optimal diameter suited for both input and output flows. This assessment becomes even more critical in systems requiring precise control over flow rates for effective temperature management within solar applications.

WHAT INSULATION OPTIONS ARE AVAILABLE FOR SOLAR PIPE INSTALLATION?

Insulating pipes effectively is crucial for preserving energy efficiency in solar installations. A multitude of insulation options exists, primarily categorized into rigid and flexible materials, each suited for specific application requirements. Rigid insulation options such as fiberglass provide excellent thermal resistance, while flexible forms like closed-cell foam offer ease of installation and adaptability to various shapes and sizes.

The choice of insulation also often hinges on regional climates and environmental exposure conditions. For instance, in areas facing extreme temperature fluctuations or prolonged sunlight exposure, employing dual layers – a thermal barrier along with reflective shielding – can help maximize heat retention. Engaging professionals to assess insulation needs based on localized factors can significantly augment system efficiency and lifespan.

In summary, determining the right pipe material for solar solenoid valve installation entails thorough consideration of multiple factors impacting system performance. A careful selection of materials, considering the specific environmental demands, flow dynamics, pressure ratings, and installation practices alongside compliance with regional codes, will significantly enhance efficiency and durability. Effectively, choices such as CPVC or PEX offer valuable properties, empowering users to create sustainable solar applications contributing to energy efficiency. Mentoring and professional input can play an invaluable role in achieving successful installation, ultimately shaping long-term satisfaction and system reliability, enhancing the overall experience within the solar landscape.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/which-pipe-should-be-installed-for-solar-solenoid-valve/