When considering the suitability of materials for solar thermal applications, aluminum tubes have distinct advantages over copper tubes, 1. Weight efficiency and ease of handling, 2. **Cost-effectiveness and affordability, 3. **Resistance to corrosion, 4. **Thermal conductivity and efficiency. Particularly, the weight efficiency of aluminum tubes not only facilitates installation but also reduces overall transportation costs, proving advantageous in scenarios where large quantities are involved. Aluminum’s lightness ensures easier handling without compromising structural integrity.

1. MATERIAL PROPERTIES AND PERFORMANCE

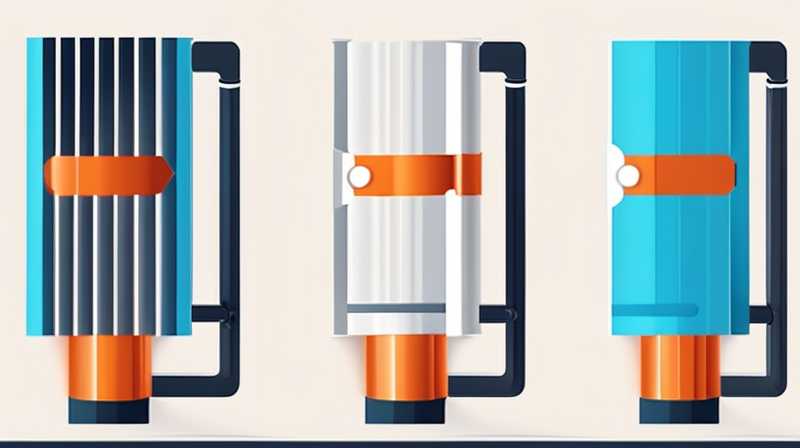

Within the realm of solar energy technology, evaluating various materials for components like tubes necessitates a deep understanding of their unique properties. Specifically, aluminum and copper demonstrate contrasting attributes that influence their performance in solar applications. Aluminum exhibits a lower density compared to copper, making it significantly lighter. This factor enhances the overall structure’s ease of installation, particularly in rooftop settings. Also, the handling of solar panels equipped with aluminum tubes becomes more practical, particularly when large arrays are deployed.

Copper, on the other hand, is known for its superior thermal conductivity, enabling efficient heat transfer in solar thermal systems. This property can lead to higher energy collection efficiencies. However, the increased weight of copper tubes poses challenges in practical applications. Installers must consider the structural support and reinforcement necessary for heavier installations, which may inadvertently increase project costs and complexity.

As the market leans towards renewable energy solutions, the material choice reflects both performance expectations and practical functionality. While copper’s thermal efficiency is often celebrated, the structural and logistical benefits of aluminum cannot be overlooked. The decision between them requires careful consideration of specific project demands.

2. COST ANALYSIS AND ECONOMIC IMPACT

Economic factors weigh heavily in the selection process for suitable materials for solar applications. Aluminum tubes generally present a lower initial investment compared to their copper counterparts, making them a more appealing option for many homeowners and businesses seeking cost-effective solar solutions. The price difference is primarily attributed to the abundance of aluminum resources, which leads to relatively lower manufacturing costs.

Furthermore, maintenance costs for solar systems can accumulate over time. Aluminum’s resistance to corrosion enhances durability and longevity, thus reducing the need for frequent replacements or repairs. In contrast, copper, although durable, can succumb to corrosion when exposed to certain environmental conditions. This vulnerability necessitates added maintenance efforts, leading to higher long-term expenses.

In addition to initial investment and maintenance costs, the total lifetime cost of solar installations must consider energy savings generated over time. Both aluminum and copper tubes contribute to energy production, but aluminum may provide higher net savings due to its affordability and low maintenance. By analyzing these economic variables comprehensively, stakeholders can make informed decisions regarding the material best suited for maximizing return on investment.

3. CORROSION RESISTANCE AND DURABILITY

The issue of corrosion resistance plays a significant role in the longevity and effectiveness of solar thermal systems. Aluminum, noted for its excellent resistance to various environmental factors, tends to withstand corrosion better than copper, especially in humid or saline conditions. This resistance is crucial for solar applications that often face fluctuating weather patterns and harsh outdoor environments.

Copper can corrode, particularly in the presence of certain chemicals or environments, which opens a conversation about long-term sustainability. Solar systems utilizing copper tubes may require additional protective measures, such as coatings or specialized materials, to ensure longevity, increasing complexity and cost in maintenance. On the flip side, aluminum’s inherent properties facilitate a more straightforward approach to installation, allowing operators to prioritize reliability without extensive protective requirements.

Moreover, the impact of corrosion on both materials extends beyond mere aesthetics. Degrading tubes can lead to inefficiencies in energy collection, forcing users to invest in repairs or replacements. The durability of aluminum tubes provides peace of mind for owners, who can expect sustained performance without frequent interventions.

4. THERMAL EFFICIENCY AND ENERGY OUTPUT

The quest for optimal efficiency in solar energy systems drives the analysis of thermal conductivity among different materials. Copper unmistakably holds an advantage here, boasting a thermal conductivity rating higher than that of aluminum. This characteristic allows copper tubes to transfer heat more swiftly from absorbed sunlight to the working fluid within the solar thermal system, potentially leading to higher energy output.

However, it is essential to recognize the advancements in thermal management technologies that have allowed aluminum to enhance its thermal performance. The effectiveness of solar tubes is not solely dependent on the material’s conductivity but also on the overall design and operational parameters of the system. Specific coatings and structural designs can optimize aluminum’s performance, thus narrowing the efficiency gap in practical applications.

When evaluating the systematic performance in energy output, factors such as temperature fluctuations, system orientation, and energy storage methods also play a critical role. Consequently, the choice between aluminum and copper tubes must be seen as part of a larger framework that encompasses the entire solar thermal system.

FAQs

WHAT IS THE MAIN DIFFERENCE IN THERMAL PERFORMANCE BETWEEN ALUMINUM AND COPPER TUBES?

The primary distinction in thermal performance relates to the thermal conductivity of copper, which is superior to that of aluminum. Copper’s ability to transfer heat quickly and efficiently enables solar systems using copper tubes to typically achieve higher temperatures more swiftly. However, advancements in thermal management and coating technologies have allowed aluminum tubes to close this performance gap considerably. In designing solar systems, the choice between the two materials may depend on specific application requirements, including budget considerations and handling preferences. Consequently, while copper may be ideal for certain high-efficiency needs, aluminum’s advancements offer viable alternatives for various solar applications.

HOW DOES CORROSION AFFECT THE CHOICE OF TUBING MATERIALS FOR SOLAR SYSTEMS?

Corrosion represents a critical factor influencing material selection for solar tubing materials. Aluminum is specifically designed for high resistance to corrosion, enabling it to endure varied environmental challenges. In contrast, copper tubes are susceptible to corrosion, especially in humid or chemically reactive conditions, which can lead to significant deteriorative impacts on performance. As a result, systems that prioritize longevity and lower maintenance are often better suited to aluminum applications. By assessing the environmental conditions of installation sites, stakeholders can navigate the material choice intelligently, considering potential corrosion risks.

WHAT ARE THE COST IMPLICATIONS OF CHOOSING ALUMINUM OVER COPPER TUBES FOR SOLAR INSTALLATIONS?

The cost implications are notably favorable towards aluminum when evaluating initial purchasing prices. Typically, aluminum tubes come at a lower cost than copper tubes, which can significantly reduce the upfront expenses for solar system installations. In the context of maintenance, aluminum’s corrosion resistance translates into reduced long-term costs associated with repairs and fluctuations in performance due to wear and failure. In contrast, opting for copper may incur greater ongoing organizational costs, attributed to potential repairs, replacements, or protective treatments due to susceptibility to corrosion. As such, a thorough cost analysis should incorporate both initial expenses and ongoing operational costs alongside the performance of each material to arrive at a comprehensive financial assessment.

The decision between aluminum and copper tubes for solar applications is nuanced, powered by a multitude of factors. Each material carries inherent advantages and disadvantages, necessitating a thorough exploration of conditions under which they will be used. While copper boasts unmatched thermal conductivity, aluminum’s lightweight nature, resistance to corrosion, lower initial investment, and decreased maintenance demands render it an appealing alternative in many solar projects. Determining which material reigns supreme largely depends on specific project needs, environmental considerations, and long-term economic implications. Ultimately, stakeholders must weigh these dimensions thoughtfully, ensuring optimal outcomes for energy efficiency, performance reliability, and cost assessments.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/which-is-better-for-solar-aluminum-tubes-or-copper-tubes/