1. THE FUNCTION OF A SOLENOID VALVE IN SOLAR SYSTEMS

The function of a solenoid valve is pivotal in the management of fluid flow within a solar heating system. This electrically operated valve serves to regulate the movement of water and facilitate the optimal functioning of the entire setup. 2. CONNECTION POINTS FOR WIRING THE SOLENOID VALVE

To properly establish connections for wiring a solar solenoid valve, one must identify the vital points where electrical wires need to be linked. 3. SELECTING APPROPRIATE WIRING MATERIALS

Choosing suitable wiring materials is essential for ensuring longevity and efficiency in the solar solenoid valve system. 4. TROUBLESHOOTING CONNECTION ISSUES

In the event of connection problems, certain troubleshooting steps should be undertaken to rectify the situation efficiently.

Summary

The correct location for connecting the wires of a solar solenoid valve involves 1. identifying the solenoid valve terminals, 2. understanding the power source connections, 3. securing insulated wire connections, 4. ensuring proper grounding. Elaborating on the first point, the solenoid valve typically has two terminals, usually marked as positive and negative, which corresponds to the polarity of the power source. It is crucial to connect the power source correctly to ensure optimal performance and prevent damage to the valve. Proper attachment of the wires promotes uninterrupted operation and enhances the longevity of the solar system’s components.

1. THE FUNCTION OF A SOLENOID VALVE IN SOLAR SYSTEMS

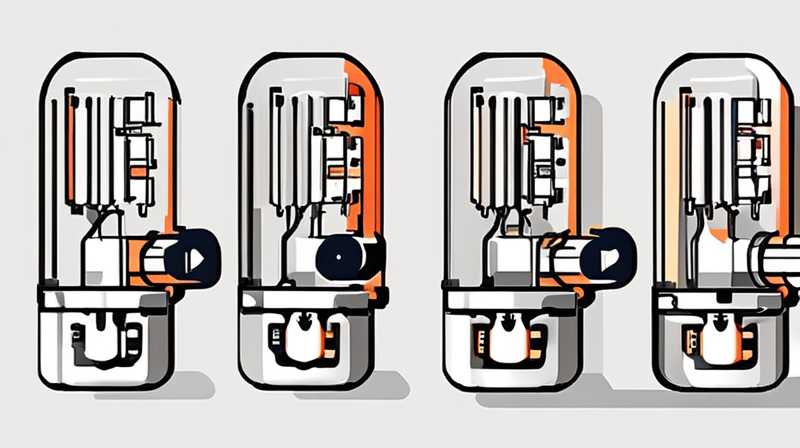

The solenoid valve plays a foundational role in solar heating applications, tasked with controlling the flow of fluids such as water or glycol within the system. Such valves serve not only to allow or prevent fluid flow but also to regulate the pressure and temperature, ensuring the system performs efficiently and safely. When the valve is energized, it opens or closes depending on the energy input, hence managing the distribution of heated fluids.

Proper function is particularly critical in solar heating systems, where the efficiency of energy transfer significantly influences the entire setup’s performance. The objective here is to ensure effective heat exchange within collectors and storage tanks, partitioning energy flow based on operational needs and environmental conditions. By preserving the appropriate fluid flow, solenoid valves ensure that the system operates at peak capacity, optimizing energy collection and minimizing waste.

The importance of this component should not be underestimated. For instance, if a solenoid valve fails or is improperly installed, the thermal dynamics of the solar system can be severely affected, leading to inadequate heating and potential damage to other system components. Understanding how these valves behave in various scenarios enables better decision-making regarding their installation and maintenance.

2. CONNECTION POINTS FOR WIRING THE SOLENOID VALVE

To harness the full functionality of a solar solenoid valve, understanding the connection points for wiring is imperative. The correct arrangement of wires ensures that the valve responds effectively to electrical signals and maintains uninterrupted fluid control.

Identifying terminals on the solenoid valve is the first step. Typically, these valves comprise two terminals labeled as normally open (NO) and normally closed (NC), indicating the valve’s default state when not powered. The terminal linked to the power source provides the energy required for the valve’s operation. For instance, when connected to a solar controller, the output signals from the controller dictate when the solenoid should activate or deactivate, based on temperature differentials or system needs.

Once the terminals have been identified, the next endeavor is to connect the valve properly to a power source. Employing weather-resistant and insulated wires will safeguard against potential environmental damage, ensuring lasting functionality. The gauge of the wire also matters; using wires that are too thin can lead to overheating, causing failure, while excessively thick wires might complicate the installation process. Utilizing color-coding for wires, typically red for positive and black for negative, further simplifies identification during the installation process.

Proper grounding of the solenoid valve is another critical aspect that should not be overlooked. A grounded system minimizes electrical hazards and enhances the safety of operations. This is particularly important in solar applications, where fluctuations in voltage can occur due to varying sunlight and system loads. Grounding helps to divert excess electrical energy away from the valve, thus prolonging its lifespan.

3. SELECTING APPROPRIATE WIRING MATERIALS

Choosing proper wiring materials is crucial for the successful operation of solar solenoid valves. Not only do these materials facilitate electrical connectivity, but they also affect the durability and reliability of the entire system. Understanding the properties of different wiring options will aid in making the best choices for installation.

Insulation material plays a significant role in deciding wire suitability. Insulated wires prevent electrical shocks and short circuits. Popular insulation materials include PVC, rubber, and thermoplastic elastomers; each possesses different properties suited for various environments. For solar applications, it is advisable to select UV-resistant and temperature-hardened insulation to withstand outdoor exposure and extreme temperature fluctuations.

Another essential consideration is the wire gauge. The American Wire Gauge (AWG) system dictates that lower numbers represent thicker wires, which can handle more current without overheating. Choosing an appropriate gauge ensures that the wires can support the electrical load imposed by the solar solenoid valve without posing any risks of damage. Thinner wires may lead to high resistance and energy loss, while excessively thick wires may be unnecessarily costly and cumbersome to install.

Mechanical durability of wiring materials is also imperative in environments prone to physical stress or adverse weather conditions. Outdoor installations face threats from wind, rain, and debris, necessitating wires that can endure such conditions without deteriorating. Wire harnesses or conduits can provide additional protection, ensuring extended longevity.

4. TROUBLESHOOTING CONNECTION ISSUES

Connection problems can arise in any system involving electrical components, and solar solenoid valves are no exception. When issues occur, taking a systematic approach can help identify and resolve the underlying causes.

The initial step in troubleshooting is to inspect the connections visually for signs of wear, corrosion, or loose fittings. Over time, exposure to moisture can create rust on terminals or damage insulation on wires, leading to connectivity issues. Disconnecting power to the system before inspection ensures safety. After a thorough examination, re-tightening connections or replacing damaged components can restore functionality.

If physical inspections do not yield answers, a multimeter can be valuable for diagnosing electrical issues. This device can test for continuity between the wires, ensuring that no breaks exist within the circuit connecting the solenoid valve. Additionally, checking voltage levels at the valve terminals ensures the proper power supply is reaching the valve, indicating whether the problem lies within the valve itself or the connected controller.

The solenoid valve can become stuck due to debris or sediment accumulation in the valve itself, potentially leading to malfunction. In such instances, disassembly and cleaning the internal components might restore proper function rather than outright replacement. Regular maintenance on these components can prevent many issues associated with dirt and debris.

FAQS

WHAT IS A SOLENOID VALVE AND HOW DOES IT WORK?

A solenoid valve is an electromechanical device used to control fluid movement within various systems, including solar heating applications. It consists of a coil, which, when energized, creates a magnetic field that shifts a plunger or armature to open or close the valve. Depending on the design, a solenoid valve can be normally open (NO) or normally closed (NC). In solar systems, solenoid valves regulate the flow of heated fluids between collectors and storage tanks, optimizing heat transfer efficiency. By providing real-time control over fluid movement, solenoid valves contribute significantly to the overall effectiveness of solar thermal systems.

HOW DO I KNOW IF MY SOLENOID VALVE IS FUNCTIONING PROPERLY?

To ascertain whether a solenoid valve is operational, several diagnostic steps can be undertaken. First, observe for any signs of mechanical failure, such as unusual noises or vibrations during operation. Listening for clicks indicates that the valve is attempting to activate. Secondly, utilize a multimeter to measure voltage at the terminals during operation, checking if it corresponds to the specifications. Finally, if feasible, verify the flow of fluid through the valve while it is activated; stagnant or low flow may suggest internal obstructions or mechanical failure. If problems persist even after these examinations, professional evaluation might be necessary to determine the valve’s condition fully.

CAN I INSTALL A SOLENOID VALVE MYSELF, OR SHOULD I HIRE A PROFESSIONAL?

Installing a solenoid valve can be a feasible task for individuals with reasonable electrical and plumbing skills. However, several factors influence whether self-installation is advisable. Those with basic knowledge of electrical systems, fluid dynamics, and safety practices may successfully perform the installation. That said, hiring a licensed professional is recommended for complex systems or if one is unfamiliar with handling electrical components. A qualified technician will ensure compliance with local building codes and best practices, enhancing safety and overall functionality of the solar system.

The functionality of solar solenoid valves is paramount for ensuring efficient fluid management in solar heating systems. Proper wiring connections, suitable materials, and proactive troubleshooting approaches are critical for maintaining operational efficacy. Mastering terminal identification and adhering to durable wiring standards safeguards the system’s integrity, while regular assessments can prevent malfunctions. With a thorough understanding of these components, both DIY enthusiasts and professionals can achieve optimal results in their solar applications. Mastery of these elements ultimately translates to enhanced operational efficiencies, prolonged equipment lifespan, and increased susceptibility to changing environmental conditions. By ensuring each of these aspects is resolved satisfactorily, success in establishing reliable and efficient solar energy collection systems can be attained. Embracing these methodologies not only enhances the functionality and efficiency of your system but also contributes positively to the sustainable energy movement. By investing time and resources into understanding and managing each component, solar energy remains a powerful, renewable energy resource that can lead to significant energy savings and environmental benefits.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/where-to-connect-the-wires-of-solar-solenoid-valve/