To effectively address the query of shutting off the solar tube valve, it is crucial to consider several aspects of the solar heating system’s functionality and maintenance. 1. Understanding the Components, 2. Identifying the Location, 3. Assessing the Conditions, 4. Following Safety Protocols. One of the most vital elements relates to understanding the specific model of the solar heating system being utilized. By comprehending the configuration and plumbing in relation to the valve, one can better assess the appropriate approach for closing it while ensuring the system’s integrity.

1. UNDERSTANDING THE COMPONENTS

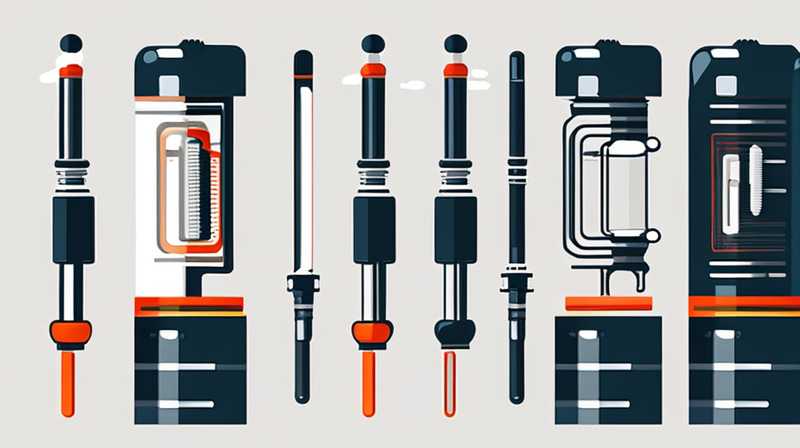

In any solar heating system, comprehending the various components is paramount to effective operation and maintenance. Solar tubes, valves, pumps, and controllers all play critical roles in the system’s functionality. Each component interacts with the others to deliver optimized heating of water, thus making it essential to understand how they function individually and collectively.

Solar tubes harness sunlight and convert it into heat energy, which is then transferred to the fluid circulating in the system. The valve regulates this flow, controlling the amount of heated fluid that enters the storage tank or the designated area for intended use. Without a solid grasp of each component’s purpose, effectively addressing the valve and making adjustments can be challenging.

In addition to solar tubes and valves, one must be informed about other parts of the system. Understanding the pump’s role in circulating fluid not only affects heating efficiency but also impacts how, when, and how much water is heated. If adjustments to the valve are made without consideration for the pump’s operation, it could inhibit overall system performance.

2. IDENTIFYING THE LOCATION

Locating the solar tube valve is essential for efficient maintenance and operation. Typically, valves are situated within close proximity to the solar collectors or connected piping. Depending on the design of the system, they may also be found in less obvious areas, making it crucial to consult the specific system diagram typically provided by the manufacturer.

To find the valve, start by inspecting the pipe runs emerging from the solar tubes, leading to the water storage tank or wherever the heated fluid is being directed. It is common for the valve to be positioned at an accessible height, allowing for straightforward operation.

Once the valve is located, ensure that it’s marked clearly to avoid confusion during future maintenance. Using color-coded labels or maintaining a detailed schema of the entire system may enhance efficiency, particularly for larger installations where components may be interconnected in complex ways. Documenting where the valve is found establishes a roadmap for any necessary interventions.

3. ASSESSING THE CONDITIONS

Prior to closing the valve, it is pertinent to assess the current state of the solar heating system. Identifying if the system is under pressure or heated is essential for a proper and safe shutoff. Checking gauges, inspecting the water temperature, and observing the flow rates can provide essential insights into the conditions of the system before any adjustments are made.

If the water temperature is significantly elevated, ensuring proper cooldown before manually engaging the valve enhances safety and avoids potential injuries or equipment damage. Furthermore, examining any pressure buildup is necessary because high pressure may lead to failures or leaks if the valve is closed abruptly. In such conditions, a gradual approach may be recommended to allow the system’s pressure to equalize before complete closure occurs.

Proper assessment involves more than just looking at gauges and indicators. Listening for any noises and monitoring the performance continuity of the entire system also serves as indicators of malfunction. Such signs, like unusual sounds or irregular flow patterns, should prompt further investigation before proceeding with any manipulations to the valve.

4. FOLLOWING SAFETY PROTOCOLS

Adhering to safety protocols is non-negotiable whenever dealing with a solar heating system. This is especially pertinent when distracting the flow of heated fluids involves potential hazards. Wearing protective gear, such as gloves and goggles, ensures safety against accidental spills or splashes while operating components like valves.

Preparation before making any modifications also includes shutting off any power supply to connecting pumps, ensuring no automated attempts on pressurized fluid circulation. Understanding the entire operation of the solar heating system involves being aware of all associated risks.

In addition to personal safety, one must examine the implications for the system’s integrity during valve adjustments. Sudden changes—like quickly closing a valve—can lead to ruptures due to thermal expansion or mechanical strain. Following cautionary measures during this process ensures that both individual safety and system longevity are prioritized.

FAQs

WHERE IS THE SOLAR TUBE VALVE LOCATED?

The valve associated with the solar tube is typically located in proximity to the solar collectors or water storage tanks. Its primary purpose is to regulate the flow of fluid through the system. Checking the installation manual provided by the manufacturer can help pinpoint its exact location. Furthermore, observing the piping layout around the collectors may reveal the valve’s placement. Given that systems can vary widely in design, if you are having difficulty locating the valve, seeking professional assistance or referring to user guides is advisable.

WHAT SHOULD I DO IF THE VALVE IS STUCK?

If you encounter a stuck valve, first assess whether it may be due to thermal expansion or corrosion. Applying gentle force can often free it, but be cautious not to damage the valve or connecting pipes. Lubricating agents like silicone spray may be beneficial; however, ensure they are suitable for plumbing applications. If the valve remains inoperable, it may need to be replaced entirely. Always shut off the system pressure before attempting any repairs or replacements to avoid hazardous situations.

HOW OFTEN SHOULD I MAINTAIN THE SOLAR TUBE VALVE?

Regular maintenance is crucial for the longevity of a solar tube system. It is generally advised to inspect valves every three to six months during routine system checks. Ensure that the valve opens and closes smoothly without any obstruction. Additionally, checking for leaks and wear on seals guarantees effective operation. If any issues arise, address them immediately to prevent more significant problems down the line. Documentation of these inspections can assist in maintaining a proactive approach toward overall system health.

The implications of operating a solar heating system hinge on understanding its intricate components and functionality. By recognizing the specific components, locating the valve, assessing conditions, and adhering to safety protocols, the procedure for closing the solar tube valve becomes more straightforward and effective. A systematic approach ensures not only personal safety but also promotes the longevity and efficiency of the solar heating system. The interconnectedness of each component plays a large role in maintaining optimal operation. Therefore, maintaining awareness of environmental conditions and operational mechanics is essential. Engaging in regular inspections, preventive measures, and knowing when to reach out for professional assistance significantly contribute to the sustainability of the system in the long run. It is crucial to be well-informed and prepared when handling the solar tube valve, ensuring both the operator’s safety and the entire system’s integrity. Following these practices establishes an effective, responsible approach to managing solar heating systems.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/where-to-close-the-solar-tube-valve/