To locate the refrigerant fill point on solar barrels, several crucial considerations must be explored. 1. Understanding the System, 2. Identifying the Fill Point, 3. Safety Precautions, 4. Tools and Accessories Needed Each of these aspects contributes significantly to the overall process, ensuring both efficiency and safety when recharging the refrigerant in solar barrels.

UNDERSTANDING THE SYSTEM

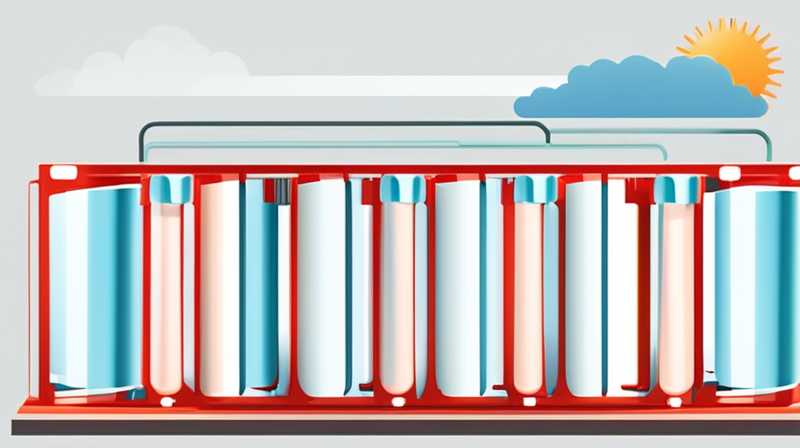

A comprehensive understanding of the refrigeration systems integrated into solar barrels is vital. Solar barrels employ refrigerant to facilitate heat transfer, playing a crucial role in heating water or other fluids using solar energy. The system typically consists of various components such as the compressor, condenser, evaporator, and expansion valve. When the refrigerant circulates through these components, it absorbs heat from the storage medium and transfers it elsewhere, contributing to the overall efficiency of the solar heating process.

The role of refrigerant within this system cannot be overstated. Refrigerants, often in liquid form, evaporate upon absorbing heat and subsequently return to their liquid state, releasing the stored heat. It is this cycle that enhances the thermal performance of solar barrels. Therefore, knowing how to properly add refrigerant is not merely a matter of convenience—failing to recharge adequately may lead to diminished performance, overheating, or even system failure. Understanding the properties of the refrigerant used, along with its compatibility with system components, is essential.

IDENTIFYING THE FILL POINT

Locating the refrigerant fill point requires the ability to distinguish between various parts of the solar barrel. Typically, the fill point is situated on or near the compressor or at a designated valve in the refrigerant lines. Identifying this location is often facilitated by consulting the manufacturer’s manual, which provides a comprehensive overview of the system, including diagrams. Manuals will often include schematics that highlight the refrigerant circuits, making it easier for technicians and homeowners to locate the fill point.

Besides referring to manuals, physical identification can also be made by observing the presence of service ports, which often look like small metal caps on the refrigerant lines. It is important to differentiate between the high-pressure and low-pressure ports, as each serves a different purpose in the overall cycle. The low-pressure port is typically larger, allowing for the addition of refrigerant, while the high-pressure port is meant for pressure readings and diagnostics. Ensuring that one is working with the right port is crucial for the effective charging of refrigerant.

SAFETY PRECAUTIONS

Safety is paramount when adding refrigerant to solar barrels, as mishandling can lead to accidents or equipment damage. Wearing appropriate personal protective equipment (PPE) such as gloves, goggles, and face shields is imperative. These precautions help minimize the risk of exposure to refrigerants, which can be harmful if they come into contact with skin or eyes. Furthermore, ensuring proper ventilation in the workspace is crucial, as some refrigerants can produce harmful fumes when vented into the atmosphere.

Another critical safety consideration involves familiarizing oneself with the properties of the specific refrigerant in use. Different refrigerants have varied characteristics, including flammability and toxicity. For example, R-410A, a common refrigerant, poses specific handling considerations due to its high-pressure nature. Proper training in the use of refrigerants, along with adherence to local and international regulations, ensures that technicians work safely and responsibly. Engaging in safety audits prior to beginning any work not only safeguards individuals but also protects the integrity of the equipment involved.

TOOLS AND ACCESSORIES NEEDED

To effectively add refrigerant to solar barrels, certain tools and accessories are indispensable. The primary tool required is a refrigerant gauge manifold set, which enables technicians to check existing pressures within the system and to determine how much refrigerant is needed. These gauges are marked with color-coded lines: blue for low-pressure and red for high-pressure. Using these gauges allows for precise measurements, which are critical for maintaining the balance of the system.

In addition to gauge sets, one may also require refrigerant tanks, vacuum pumps, and scales for accurately measuring the amount of refrigerant added. A vacuum pump is particularly beneficial for removing air and moisture from the lines before refrigerants are introduced, preventing contamination and ensuring optimal system performance. Lastly, having a set of wrenches and screwdrivers on hand for securing fittings can streamline the process, allowing for efficient handling of the task without unnecessary interruptions.

COMMON TECHNIQUES FOR ADDING REFRIGERANT

There exist a variety of techniques to add refrigerant to solar barrels efficiently. 1. Connect the Manifold Gauges, 2. Evacuate the System, 3. Introduce the Refrigerant, 4. Monitor System Performance Each of these steps must be executed with precision to ensure an effective recharge and optimal system operation.

Initially, one must connect the manifold gauges to the ports identified earlier. The blue hose connects to the low-pressure side while the red hose is secured to the high-pressure side. Opening the valves allows pressure measurements and prepares the system for the next steps. It’s crucial to ensure the manifold gauges are functioning correctly and reading accurately before proceeding to evacuate the system.

Once the gauges are attached, the next step is to evacuate the system. Utilizing a vacuum pump removes any air and moisture trapped in the lines. Failure to adequately evacuate can lead to serious system efficiency problems, including freezing and compressor failure. Monitoring the vacuum gauge is essential here; a perfect vacuum will indicate that most contaminants have been drawn out. After achieving a robust vacuum, one can proceed to introduce the refrigerant.

Obtaining the correct quantity of refrigerant is vital. It is advisable to refer to the manufacturer’s specifications, as systems vary in refrigerant requirements. Opening the refrigerant tank while observing the manifold gauges will facilitate introducing the refrigerant into the system. Be meticulous during this phase, as excessive refrigerant can also lead to inefficiencies and system malfunction.

After the refrigerant has been charged, careful monitoring of system performance is necessary. Observing gauge pressures and operational temperature will confirm whether the system is functioning correctly. If readings are abnormal, revisiting previous steps or making necessary adjustments is advisable. Conducting a thorough final inspection of the entire system, coupled with ensuring there are no leaks or performance issues, guarantees long-term operation.

MAINTENANCE CONSIDERATIONS POST-REFRIGERANT ADDITION

Following the introduction of refrigerant, maintenance plays a pivotal role in sustaining system performance. Developing a regular maintenance schedule enables homeowners and technicians to identify any potential issues that may arise, ensuring that the system operates effectively. This will typically include checking refrigerant levels, inspecting for leaks, and verifying functionality of key components like the compressor and evaporator.

Regular maintenance helps maintain the longevity of the solar barrel system. Inspecting connections and seals routinely is essential as wear and tear can compromise system efficiency over time. Additionally, ensuring the cleanliness of components such as the condenser coils will help prevent overheating and aid in heat exchange efficiency. By consistently addressing these areas, the overall operational health of the entire system will improve, maximizing its efficiency.

Furthermore, advancements in technology offer tools and systems that can assist in maintaining optimal performance. Smart sensors and automated systems now exist that provide real-time monitoring of operating parameters. Incorporating such technology into maintenance routines can provide valuable insights, allowing for preemptive measures and reducing the likelihood of unexpected operational failures. Keeping abreast of technological advances related to solar barrels and refrigerant management is crucial for achieving the best system performance.

FREQUENTLY ASKED QUESTIONS

HOW OFTEN SHOULD REFRIGERANT BE ADDED TO SOLAR BARRELS?

Maintaining the right amount of refrigerant in solar barrels is key to sustaining operational efficiency. The frequency of adding refrigerant primarily depends on the system’s design, usage patterns, and the presence of any leaks within the system. Generally speaking, it is advisable to conduct a thorough inspection of refrigerant levels at least once a year. During this inspection, technicians can check for leaks, verify proper functioning of key components, and assess overall system performance.

If leaks are detected, it is crucial to address them promptly before recharging with refrigerant. Continuous leakage can distort system performance, leading to increased energy consumption and dampened efficiency. In some cases, systems that are predominantly subject to fluctuating temperatures might lose refrigerant faster, necessitating more frequent checks. By implementing a proactive approach to refrigerant management, potential failures can be minimized, preserving the longevity and effectiveness of the solar barrel system.

WHAT SHOULD I DO IF MY SOLAR BARREL IS LOW ON REFRIGERANT?

Detecting low refrigerant levels in a solar barrel is a matter that requires immediate attention. The first step is to stop using the system to prevent further damage, as operating a refrigeration system with insufficient refrigerant may lead to compressor failure or other mechanical issues. Once the system is turned off, it’s wise to conduct a thorough leak inspection. Utilizing soapy water to check connections and seals for bubbling can help isolate sources of leakage.

If no leaks are readily apparent, enlisting the services of a qualified technician may be necessary. Refrigerant addition is not a do-it-yourself endeavor; it demands knowledge of the system, adherence to safety protocols, and specialized equipment. Technicians can assess the situation more accurately and can provide insights into potential problems or upgrades that may enhance the system’s performance. Proper documentation of any repairs or maintenance conducted will also ensure optimal functionality in the future.

CAN I USE ANY REFRIGERANT FOR MY SOLAR BARREL SYSTEM?

Solving the dilemma of choosing the right refrigerant is paramount when it comes to solar barrel systems. The compatibility of refrigerants varies significantly; therefore, verifying the manufacturer’s specifications is vital. Using the wrong refrigerant may compromise performance and even void warranties, leading to significant financial consequences in the long term.

Most systems are designed for specific types of refrigerants, such as R-410A, R-134A, or others. Substituting these with other variants can lead to chemical incompatibilities that result in operational inefficiencies or system damage. Hence, it is advisable to only use refrigerants explicitly recommended by the manufacturer of the solar barrel. By sticking to prescribed standards, one ensures that the system performs at an optimal level, prolonging its life and improving energy efficiency.

A comprehensive understanding of where to add refrigerant to solar barrels encompasses several crucial aspects including system knowledge, identification of access points, essential safety precautions, and the necessary tools for recharging. Addressing these key elements ensures both an efficient and safe approach to the refrigeration process. It is fundamental to familiarize oneself with the specifics of the refrigerant in use and to adopt a proactive mindset towards maintenance and performance assessment. Regular checks paired with the right techniques not only enhance the longevity of the system but also ensure its robust functionality. Ultimately, informed usage of refrigerants and adherence to best practices contribute significantly to sustainable energy management in solar heating systems, yielding benefits that extend to the efficiency and environmental impact of renewable energy solutions.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/where-to-add-refrigerant-to-solar-barrels/