Where is the spring of the solar solenoid valve

1. The spring of a solar solenoid valve is typically located within the valve assembly, integrated into the internal mechanism designed for regulating fluid flow. 2. It functions by providing the necessary force to either open or close the valve in response to electrical signals. 3. Understanding its position and role is critical for maintaining optimal operation and preventing malfunctions. 4. The precise location may vary depending on the design and manufacturer, but it usually resides adjacent to the plunger within the solenoid body. 5. This component’s performance impacts the overall efficiency of the solar water heating system, emphasizing the importance of regular inspection and maintenance.

1. UNDERSTANDING SOLENOID VALVES

Solenoid valves play a crucial role in various applications, particularly within solar energy systems. These electrically controlled valves manage the flow of fluids, ensuring proper circulation in heating systems. The fundamental principle behind solenoid valves revolves around an electromagnetic coil, which, when energized, generates a magnetic field. This magnetic field acts upon a movable plunger or armature, triggering the opening or closing of the valve.

The construction of a solenoid valve typically includes several key components: the solenoid coil, the valve body, a plunger, and a spring. The combination of these elements enables efficient operation. In solar applications, effective control of fluid flow is vital, as it directly influences system performance and energy efficiency. With the increasing adoption of solar technology, knowledge of solenoid valve mechanisms becomes increasingly important for manufacturers, installers, and end-users alike.

2. THE ROLE OF THE SPRING IN SOLENOID VALVES

At the heart of a solenoid valve’s operation lies the spring, which is a critical component responsible for ensuring that the valve returns to its default position when the electric current is removed. The spring’s design and material can significantly influence the valve’s responsiveness and durability. Generally, springs are made from high-quality steel or other materials that provide both strength and resilience, allowing them to withstand repeated cycling.

When the solenoid coil is energized, it generates a magnetic force that pulls the plunger upward, overcoming the tension in the spring. As the plunger moves, it either opens or closes an orifice that allows or restricts fluid flow. Once the electrical signal is turned off, the spring takes over, pushing the plunger back into its original position, thus re-establishing the flow path or stopping fluid movement. This action highlights the importance of the spring’s functionality in facilitating efficient operation in solar systems, underlining the need for meticulous engineering and design.

3. LOCATING THE SPRING IN THE VALVE ASSEMBLY

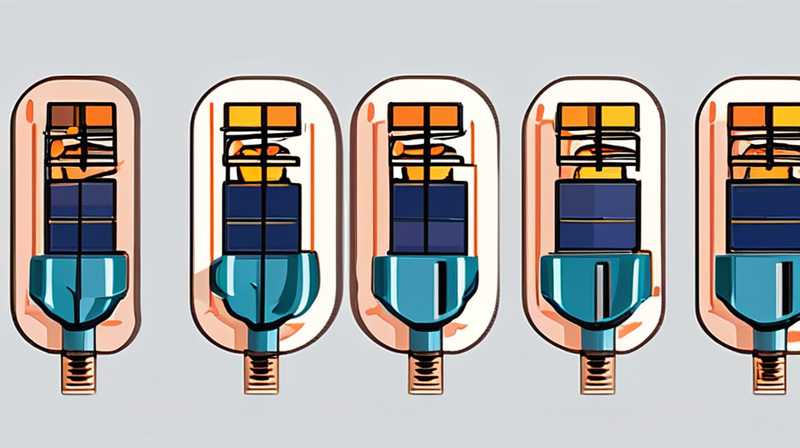

When examining a solar solenoid valve, identifying the position of the spring is essential for troubleshooting and maintenance. The spring is typically situated within the solenoid assembly, directly connected to the plunger. To visualize the arrangement, consider the valve body housing the solenoid coil, with the plunger residing inside. The spring is placed under the plunger, allowing it to compress and expand as the coil is energized and de-energized.

In many designs, the spring is enclosed within the solenoid housing, specifically designed to ensure that it remains properly aligned and functioning. Some advanced solenoid valves offer modular construction, enabling easier access for maintenance and repairs. Recognizing the spring’s position helps technicians diagnose issues effectively, should the valve exhibit problems such as failure to open or close properly.

4. IMPACT OF SPRING TENSION ON PERFORMANCE

The tension of the spring directly affects the responsiveness of the valve. A spring with insufficient tension may lead to delayed operation, causing the valve to remain partially open or closed even when electrical signals are applied. In contrast, an overly tight spring can cause excessive wear on the plunger and solenoid components, leading to premature failure. Finding the right balance is crucial for ensuring reliable performance, particularly in solar applications where efficiency is paramount.

Furthermore, the spring’s material properties can influence its longevity and performance consistency. Environmental factors such as temperature and humidity may also impact spring performance. Therefore, selecting high-quality materials and designing for variable conditions are essential considerations for engineers and manufacturers working with solar solenoid valves.

5. MAINTENANCE OF SOLENOID VALVES

Regular maintenance of solenoid valves, including attention to the spring, is vital to ensuring optimal performance and longevity. Technicians should conduct periodic inspections to check for signs of wear and tear, corrosion, or other damage that could affect valve function. One key area of focus should be the spring, as failure to detect a weakened or malfunctioning spring could lead to valve failure.

Lubrication is another important aspect of maintaining solenoid valves, including the spring mechanism. Proper lubrication reduces friction, allowing the plunger to move freely and efficiently. However, care should be taken to use appropriate lubricants that do not adversely affect the valve materials. Developing a maintenance schedule that incorporates these checks will help prevent costly repairs and downtime in solar heating systems.

FAQs

WHERE CAN I FIND A REPLACEMENT SPRING FOR A SOLAR SOLENOID VALVE?

To obtain a replacement spring for a solar solenoid valve, it is advisable to contact the manufacturer of the valve directly. Many companies offer spare parts for their products through official websites, customer service departments, or authorized distributors. Additionally, HVAC supply stores and online platforms specializing in solenoid valves may carry compatible springs. Before purchasing, ensure that you have the specific model number and specifications to guarantee compatibility with your existing valve. If unsure about the correct part, consult the original equipment manufacturer (OEM) or refer to the product manual for guidance.

HOW DOES THE SPRING AFFECT THE VALVE’S OPERATION?

The spring significantly influences the operation of a solenoid valve by controlling the closing and opening mechanisms. Once the electrical current is removed from the solenoid coil, the stored tension in the spring pushes the plunger back into its default position, thereby stopping or allowing the flow of fluid. If the spring tension is inadequate, the valve may not close fully, leading to leaks or inconsistent flow. Conversely, a spring that is too tight can hinder the plunger movement, risking valve malfunction. Therefore, the spring’s design, material, and tension are vital for optimal valve performance, particularly in solar heating applications where efficiency is essential.

WHAT SIGNS INDICATE A PROBLEM WITH THE SPRING IN A SOLENOID VALVE?

Several indicators may suggest a problem with the spring in a solenoid valve. Common signs include failure of the valve to open or close completely, intermittent operation, or a delayed response when the valve is activated. Additionally, unusual noises during operation, such as grinding or excessive vibration, may indicate that the spring is either damaged or misaligned. In some cases, physical examination of the spring for signs of corrosion, breakage, or deformation is necessary. Regular maintenance inspections can help identify these issues before they lead to greater system failures, allowing for timely repairs and ensuring continued system performance.

Certainly, delving into the intricacies of a solenoid valve, particularly in relation to solar applications, sheds light on a critical component often overlooked. Grasping its operation, especially the function and location of the spring, is pivotal. Maintaining this part not only ensures the efficiency of the valve but also enhances the overall performance of solar energy systems. As solar technology advances, an intricate understanding of every component becomes essential for achieving energy efficiency and sustainability. Adopting best practices for monitoring and maintenance ensures that systems run smoothly, preventing issues that could result in energy loss. In light of rising energy needs and environmental concerns, focusing on robust technology that integrates efficient fluid dynamics is paramount.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/where-is-the-spring-of-the-solar-solenoid-valve/