Where is the solar solenoid valve pressed?

The solar solenoid valve is pressed at the connection point between the valve and the solar panel system or hot water storage tank, pivotal for regulating the flow of fluids. 1. This pressing occurs during installation and maintenance, ensuring watertight seals are achieved. 2. Proper pressing techniques are essential for preventing leaks and ensuring operational efficiency. 3. The pressing process is often accompanied by guidelines and specifications which must be followed meticulously. 4. This mechanism plays a critical role in optimizing solar energy systems by enabling or disabling fluid flow in response to temperature changes.

1. FUNCTIONAL OVERVIEW OF SOLENOID VALVES

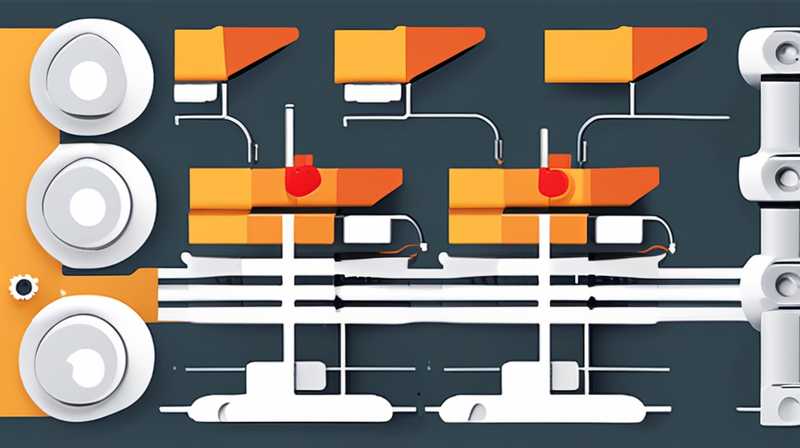

Delving into the fundamental aspects of the solar solenoid valve, it becomes apparent that these devices serve an indispensable role in solar energy systems. The primary function of a solenoid valve is to act as an electromechanical switch, controlling the flow of fluids within a circuit. These valves are especially vital in solar water heating systems, where they help manage the circulation of heat transfer fluids, such as water or antifreeze. The integration of solenoid valves allows for efficient regulation of temperature and flow rates, critical for optimizing the performance of solar thermal systems.

The design of the solar solenoid valve typically features a coil that, when energized, creates a magnetic field, prompting the valve to either open or close. This design ensures rapid and efficient operation, allowing for the precise control of fluid pathways. Their ability to function under varying electrical conditions showcases the versatility of these valves, making them suitable for various applications, including residential, commercial, and industrial solar systems.

2. PRESSING IN INSTALLATION

When installing solar solenoid valves, the pressing technique is a critical step that requires attention to detail. During installation, the valve must be firmly pressed into the designated connection points, typically at the junctions with the piping system or the hot water tank. Ensuring a secure connection prevents leaks, which can compromise the entire solar system’s efficiency. The manual or automated pressing techniques used can significantly affect the long-term durability of these connections.

Moreover, the equipment used for pressing, such as hydraulic or pneumatic tools, determines the pressure exerted on the valve connections. Application of adequate pressure is crucial; too little pressure may lead to insufficient sealing, while excessive force could damage the valve or surrounding components. Thus, following manufacturer specifications during pressing, including torque settings and sealing methods, is paramount in achieving optimal installation results.

3. PRESSING DURING MAINTENANCE

Routine maintenance of solar solenoid valves involves periodic assessment of the pressed connections to ensure their integrity. Leaking connections often necessitate re-pressing or reseating the valve, prompting technicians to reevaluate the conditions that led to the failure. Understanding and identifying the typical wear and tear that affects valve connections during maintenance is essential for long-term system reliability.

Furthermore, the maintenance schedule must align with the solar system’s overall health. Regular inspections can pinpoint issues early, allowing for timely interventions that may include resealing or complete replacement of valves. The use of non-destructive testing methods can assist in identifying hidden problems without necessitating disassembly, thereby facilitating smoother maintenance routines.

4. OPTIMIZING SOLAR SYSTEM PERFORMANCE

The overall performance of a solar energy system can be significantly influenced by the efficiency of its solenoid valve. Properly functioning valves enable greater control over fluid flow, which translates to enhanced heating capacity and improved energy efficiency. This efficacy ensures that the solar system can deliver hot water consistently, ultimately resulting in lower operational costs and higher returns on investment.

Furthermore, advancements in smart technology are paving the way for solenoid valves that can be monitored remotely. Integration with smart home systems enables real-time tracking of valve performance, providing data that can lead to improved system management. As technology continues to evolve, the relationship between solenoid valves and solar performance will likely grow even more intertwined, pushing for innovations that further enhance sustainability.

FAQs

WHAT IS A SOLENOID VALVE AND WHY IS IT IMPORTANT?

A solenoid valve is an electromechanical device that controls the flow of fluids in a system by using an electromagnetic coil to open or close a valve. The significance of solenoid valves extends to their various applications across industries, including irrigation, HVAC systems, and solar energy systems. In the context of solar energy, solenoid valves play a vital role in managing fluid dynamics to optimize energy efficiency and fluid movement. This capability is crucial, as improper fluid flow can lead to heat loss or inadequate heating, severely affecting system performance. Their importance also lies in facilitating automation, allowing systems to react dynamically to changing conditions, such as temperature variations in solar thermal applications.

HOW DOES THE INSTALLATION PROCESS OF SOLENOID VALVES WORK?

The installation process of solenoid valves involves several steps to ensure proper function. Initially, careful consideration is given to the placement of the valve to guarantee optimal flow direction and ease of access for maintenance. Once positioned, the valve is typically connected to the piping using appropriate fittings, which may include pressed connections. The pressing technique must be executed meticulously to form a secure joint. Additionally, any electrical wiring necessary to power the solenoid must be installed, ensuring that connections are insulated and protected from environmental factors. Following installation, system functionality should be tested to confirm that the solenoid valve operates correctly, as this verifies proper sealing and flow control.

WHAT MAINTENANCE DOES A SOLENOID VALVE REQUIRE?

Maintenance of a solenoid valve entails regular inspections to evaluate both the mechanical and electrical components. A visual examination for signs of leaks or corrosion at the pressing points is crucial, along with checking for functionality by activating the valve and ensuring it opens and closes promptly. Any discrepancies detected during these checks may necessitate addressing the pressing or replacing components as needed. Routine cleaning and lubrication of the valve mechanism can further prevent blockages and assist in maintaining free movement. Additionally, understanding the manufacturer’s maintenance guidelines enables effective scheduling of service interventions, aligning with overall system upkeep to ensure sustained performance.

In summary, pressing solar solenoid valves is a critical aspect that directly impacts the efficiency and functioning of solar energy systems. Adequate pressing during installation ensures secure connections that prevent leaks and support the system’s overall integrity. Routine maintenance, which includes assessing the pressed connections, guarantees that any issues are identified and rectified in a timely manner, thus prolonging the lifespan of the valve and the entire system. The growing integration of smart technologies provides further opportunities to optimize solenoid valve performance through real-time monitoring and data analysis, promising a future of enhanced efficiency in solar applications. As solar technology continues evolving, the emphasis on pressing techniques and their significance within overall system performance will only amplify, underscoring the necessity for adherence to industry standards and maintenance best practices.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/where-is-the-solar-solenoid-valve-pressed/