To ensure the proper functioning of a solar solenoid valve, specific connections are crucial. 1. Connect to the power supply, 2. Connect the solenoid’s ground, 3. Use weather-resistant wiring, 4. Ensure polarity is correct. All wiring should be conducted with care to prevent malfunctions. For example, the connection to the power supply must match the voltage specifications of the valve to ensure operational integrity. Additionally, using weather-resistant wiring is imperative in protecting the connections from environmental elements, which can lead to corrosion or short circuits.

1. UNDERSTANDING SOLENOID VALVES

In the realm of irrigation and fluid control systems, a solar solenoid valve serves a pivotal role in automating the flow of water. This type of valve operates by using an electric solenoid, a coil of wire that generates a magnetic field when an electric current passes through it. The key function of the solenoid valve is to open or close the flow of water, controlled by an electrical signal from a solar-powered source. Understanding how these components work together is essential for effective installation and operation.

A solar solenoid valve typically integrates with systems that harness solar energy, thereby offering an eco-friendly alternative to traditional electric systems. These valves contribute to energy efficiency, particularly in remote areas where conventional power sources may not be readily available. When installed correctly, a solar solenoid valve can greatly enhance the efficiency of irrigation systems, allowing for better water management and conservation.

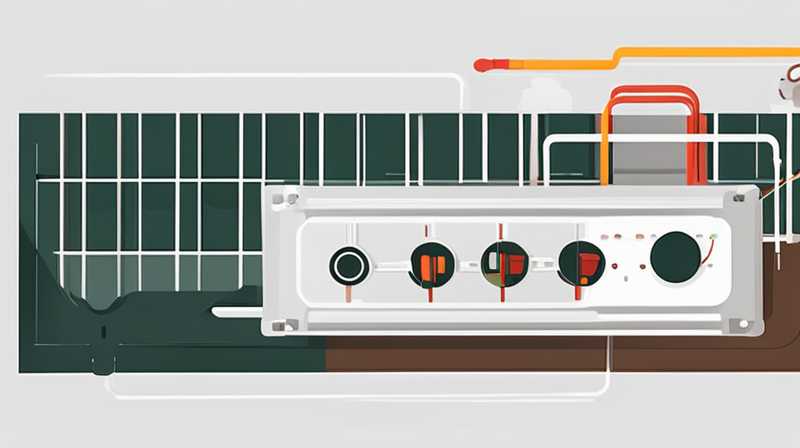

2. CONNECTIONS REQUIRED

Connecting the wires to a solar solenoid valve entails a precise understanding of both electrical requirements and the valve’s operational necessities. Proper wiring ensures the solenoid receives the correct voltage and operates reliably. Inappropriately connected wires can lead to malfunctions, reduced efficiency, or even permanent damage.

The first connection involves the power supply. Users must ensure that the voltage supplied matches the specifications outlined by the valve’s manufacturer. For instance, many solar solenoid valves operate on 12V or 24V systems, depending on the design. Next, it is imperative to ground the solenoid, which helps in preventing electrical shock and improves operational stability. The grounding process safeguards all components of the system, preventing erratic behavior and unexpected failures.

Weather-resistant wiring is another critical aspect of connecting a solar solenoid valve. Given that many of these systems are exposed to outdoor elements, using durable wiring prevents issues stemming from moisture, UV rays, and temperature fluctuations. Additionally, maintaining correct polarity in the wiring connections is vital since reversing the connections can cause the solenoid to malfunction.

3. TROUBLESHOOTING COMMON ISSUES

Despite careful installation, issues may still arise with solar solenoid valves. Common problems include failure to engage, inconsistent flow rates, and responsiveness to solar power fluctuations. Understanding how to troubleshoot these issues allows for effective maintenance and long-term reliability of the system.

One prevalent issue is the failure of the solenoid valve to activate. This can often be attributed to improper wiring, specifically the power supply connection or the grounding wire. To troubleshoot, users should first verify that the power connection is secure and that the solar panel is receiving adequate sunlight. If the solenoid does not activate, checking the continuity of the wiring with a multimeter can pinpoint the failure point.

Inconsistent flow rates can occur due to debris clogging the valve or improper sizing of the valve for the intended application. Routine maintenance, such as cleaning the valve and ensuring that it is appropriately sized, contributes significantly to mitigating this issue. Taking time to inspect the valve routinely ensures that any wear and tear is addressed before it affects performance.

4. SAFETY PRECAUTIONS AND RECOMMENDATIONS

When working with electrical systems, safety should be the paramount concern. Users must adhere to specific safety practices to avoid electrical hazards, especially when connecting a solar solenoid valve. Ensuring the system is powered down during installation and following manufacturer guidelines are key aspects of safe installation.

Proper installation is not solely a matter of connecting wires; it also involves understanding local codes and regulations regarding electrical installations. Consulting with local electricians or experts knowledgeable about solar installations can provide valuable insights and ensure compliance with safety standards. Always use components designed for outdoor use to prevent hazards related to water exposure.

Another essential recommendation is to create an accessible installation setup. This practice allows for easy maintenance and checks, ensuring that any potential issues can be addressed swiftly without dismantling larger sections of the setup. Including easy-access installation can save time and ensure that the solar solenoid valve remains in optimal working condition.

5. INSTALLATION TIPS

For those keen on installing a solar solenoid valve effectively, certain practices can enhance the overall experience and outcome of the installation. Planning the setup beforehand is crucial, as it allows for a systematic approach to wiring and placement. Such foresight can facilitate the proper alignment of the valve, ensuring it operates seamlessly.

When planning the installation, it is advisable to consider the proximity of the valve to the solar panels. The distance between the two components affects power delivery, as longer runs can result in voltage drops. Keeping the electronic connections as direct as possible will not only enhance performance but also reduce potential points for failure.

Moreover, users should invest in quality materials. Using high-grade wiring and connectors will withstand environmental factors, thereby increasing the longevity of the installation. It may seem tempting to cut costs on wiring or auxiliary components, but quality often dictates the durability and reliability of the entire installation.

FREQUENTLY ASKED QUESTIONS

WHAT IS A SOLENOID VALVE, AND HOW DOES IT WORK?

A solenoid valve is an electromechanical device used to control the flow of fluids. It consists of a solenoid (a coil of wire) and a valve element. When current flows through the solenoid, it creates a magnetic field that either opens or closes the valve, allowing or stopping fluid flow. These valves are prevalent in irrigation systems, HVAC systems, and various industrial applications, providing precise control over fluid movement through the actuation of an electrical signal. The operation is typically quick and can be automated, making solenoid valves integral to many systems.

HOW CAN I EFFECTively MAINTAIN MY SOLAR SOLENOID VALVE?

Regular maintenance is crucial to the longevity and reliability of a solar solenoid valve. Begin by routinely inspecting the electrical connections to ensure they remain secure and free from corrosion. Cleaning the valve itself can prevent blockages that interfere with its operation. Additionally, checking the solar panel’s condition and ensuring it receives adequate sunlight can contribute positively to the overall function of the valve. Finally, conducting periodic checks on the system’s performance may help in identifying any inefficiencies before they escalate into significant issues.

CAN I INSTALL A SOLAR SOLENOID VALVE MYSELF?

Indeed, many individuals choose to install solar solenoid valves independently, particularly those with a basic understanding of electrical systems and irrigation setups. However, it is essential to follow manufacturer specifications and safety protocols closely. Reading installation guides and consulting resources can significantly improve the chances of successful installation. If doubt arises, enlisting the services of a professional is recommended to ensure the installation is both safe and effective.

Attention to detail plays a fundamental role in ensuring the reliable operation of solar solenoid valves. By meticulously connecting the appropriate wires and adhering to installation guidelines, one can foster a system that enhances efficiency and sustainability. The wiring connections must align with the specifications provided by the manufacturer. Ensuring the power source and ground connection are secure, alongside using weather-resistant materials, are all pivotal elements. Recognizing potential pitfalls during the installation can lead to a smoother process and prevent future issues. Thus, taking the time to research, plan, and implement best practices is vital to achieving optimal performance in solar solenoid systems.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-wires-should-be-connected-to-the-solar-solenoid-valve/