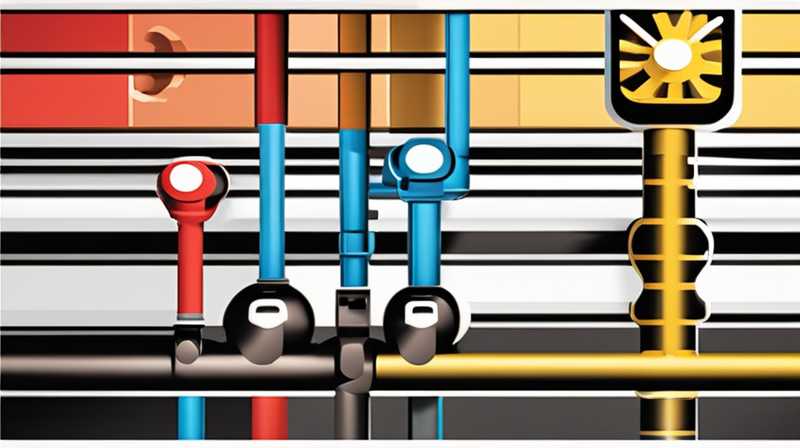

1. Solar thermal systems utilize several types of valves to optimize performance and ensure efficiency. Commonly employed valves include 1. check valves, 2. ball valves, 3. thermostatic valves, and 4. pressure relief valves. Each valve serves a distinct function, contributing to the seamless operation of solar tubes. For example, check valves prevent backflow, ensuring that heated fluid flows in one direction, which is critical for maintaining system integrity. Other valves like ball valves enable easy shut-off and flow regulation, allowing users to effectively manage the fluid circulation. The selection of appropriate valves is essential in enhancing energy efficiency and extending the lifespan of solar thermal systems.

1. CHECK VALVES

Check valves play a pivotal role in solar thermal systems. Their primary function involves preventing backflow in fluid lines, ensuring that the heated fluid moves in a singular, uninterrupted direction. This action is critical in maintaining optimal efficiency in solar tube systems, as any backflow could lead to a decrease in the overall thermal efficiency of the system. If a check valve fails, it can lead to substantial losses in energy, resulting in decreased system performance. Furthermore, the positioning of check valves is also essential; they must be installed in a manner that allows for efficient functioning without obstructions that could complicate fluid movement.

In addition to their operational importance, check valves contribute to the longevity of solar thermal components. By preventing backflow, they mitigate wear and tear on fittings and pipes, potentially saving costs related to maintenance and replacement of parts. When selecting check valves for solar tube systems, considerations such as the material of the valve, its size, and the specific flow requirements are essential. Ensuring compatibility with the fluid type, whether it be water or a glycol mixture, is also critical for effective performance, as improper materials can lead to corrosion or deterioration of the valves. Overall, the implementation of effective check valves ensures that solar thermal systems operate at peak efficiency while minimizing maintenance needs.

2. BALL VALVES

Ball valves are another critical component in managing flow within solar thermal systems. Their design allows for quick on/off control of fluid flow, making them particularly useful during system maintenance or when adjustments to fluid circulation are necessary. The simplicity of ball valves, featuring a spherical disc that rotates within the pipe, provides an effective way to regulate the flow of hot fluid from the solar collector to the storage tank. This functionality plays a significant role in the management of energy transfer processes that characterize solar tube systems.

The importance of ball valves extends beyond mere flow control. Their robust design is well-suited for high-temperature applications often found in solar thermal systems, ensuring durability even under rigorous service conditions. Moreover, the installation of ball valves enhances the safety profile of solar thermal systems. By providing users with a reliable means to shut off flow quickly, ball valves can mitigate risks associated with overpressure or leaks, contributing to a safer operating environment. When selecting ball valves, factors to consider include the valve’s pressure rating, compatibility with the thermal fluid, and resistance to corrosion and damage from UV exposure. The integration of ball valves ultimately brings efficiency, safety, and reliability to solar thermal systems.

3. THERMOSTATIC VALVES

Thermostatic valves function by automatically regulating the flow of heated fluid based on temperature variations, thereby enhancing the efficiency of solar tube systems. By continually monitoring the temperature of the circulating fluid, these valves adjust the flow rate to maintain optimal thermal levels within the system. This function is particularly beneficial in preventing overheating and ensuring that the heat transfer process remains efficient regardless of external conditions, such as fluctuating sunlight.

Installing thermostatic valves reduces energy consumption by allowing the system to work more effectively with varying thermal loads. They automatically opens and closes based on the temperature settings, which aids in balancing the overall energy output of the system. Additionally, these valves can prevent thermal shock, which can occur when hot fluid rapidly enters cooler parts of the system, causing damage or inefficiencies. For this reason, when selecting thermostatic valves for solar thermal systems, it’s imperative to consider their temperature rating, calibration, and compatibility with the fluids in use. Integrating well-functioning thermostatic valves can lead to more consistent and efficient operation within solar thermal installations.

4. PRESSURE RELIEF VALVES

Pressure relief valves are crucial safety devices in solar thermal systems, designed to prevent excessive pressure build-up within the pipes and storage tanks. By automatically releasing excess pressure when predefined limits are reached, these valves ensure that the system operates within safe parameters. Without their presence, a malfunction or blockage could escalate into dangerous scenarios, including pipe bursts or system failures that could compromise safety and performance.

The selection and proper installation of pressure relief valves require careful consideration of the system’s maximum allowable pressure ratings, fluid types, and operational temperatures. Choosing a valve that can withstand the specific conditions of solar thermal systems is essential for effective functioning. Regular maintenance and testing of these valves are paramount to ensure they operate correctly when their pressure thresholds are surpassed. Many systems have added features such as automatic testing or monitoring capabilities that can alert users to potential issues before they escalate. Pressure relief valves significantly enhance the safety, reliability, and overall integrity of solar thermal systems by safeguarding against potential overpressure conditions.

5. COMPARATIVE ANALYSIS OF VALVE TYPES

To effectively determine which valves to incorporate within solar tube systems, understanding the nuances between different valve types can provide clarity. While check valves predominantly focus on preventing backflow, ball valves serve in facilitating immediate flow control for maintenance. Thermostatic valves adjust the flow dynamically, addressing temperature changes, while pressure relief valves act as safety nets during system failures.

The optimal selection may also depend on specific application requirements. For instance, in systems where temperature control is paramount, thermostatic valves may take precedence. Conversely, installations prioritizing safety might emphasize pressure relief valves. Ultimately, a thorough understanding of each valve’s functionality, advantages, and applications enables better design and operational decisions, ultimately improving the efficiency and longevity of solar tube systems.

6. MAINTENANCE OF VALVES IN SOLAR SYSTEMS

Regular maintenance plays an essential role in the sustained performance of valves fitted within solar thermal systems. Preventative measures including routine inspections and prompt repairs can prolong the life of valves, ensuring that they function effectively over time. Maintenance schedules can vary depending on the type of valve and its exposure to operational stresses; however, general practices include checking for leaks, ensuring proper alignment, and verifying the functionality of mechanisms.

In addition to scheduled maintenance, users should remain vigilant regarding any unusual signs of wear or performance issues. For instance, a ball valve may have difficulty turning, indicating that the mechanism may be getting jammed or corroded. Recognizing these symptoms early on can allow for timely interventions that prevent more significant failures. Restoration work often involves replacing seals, lubricating mechanisms, and ensuring that any dirt or contaminants are fully cleaned from the valve area. Adopting practices that emphasize valve health not only enhances system performance and reliability but also minimizes unplanned downtime and reduces overall maintenance costs.

3.

FREQUENTLY ASKED QUESTIONS

WHAT IS THE ROLE OF CHECK VALVES IN SOLAR SYSTEMS?

Check valves primarily serve the function of preventing backflow within solar thermal systems. When heated fluid circulates through the system, check valves ensure that the fluid only moves in one direction—typically from the solar collector to the storage tank. This function is crucial for maintaining efficient energy transfer and preventing energy losses that can occur if hot fluid flows back into the collector or other parts of the system. The effectiveness of check valves minimizes wear and tear on system components by preventing corrosive backflow and maintaining the intended flow direction.

Additionally, it is important to select check valves that are compatible with the specific thermal fluids in use, whether they be water or other heat transfer fluids. Ensuring that the materials used in the valve’s construction can withstand the temperatures and pressures generated in a solar thermal system is essential for reliable performance. Proper installation and regular maintenance checks are also necessary to identify any potential issues before they can impact system efficiency or reliability.

HOW DO BALL VALVES IMPROVE CONTROL IN SOLAR THERMAL SYSTEMS?

Ball valves enhance the control and management of fluid flow within solar thermal systems by providing easy on/off functionality. This immediate flow regulation is vital during system adjustments, maintenance, or when isolating sections of the system for servicing. Because ball valves feature a spherical disc that rotates to control flow, they can provide a quick response when users need to shut off fluid movement, helping prevent leaks or accidents.

Furthermore, the robust design and ability to handle high-pressure and high-temperature applications make ball valves a strong choice for solar thermal systems. Users appreciate their simplicity and efficiency, which translates to less downtime during maintenance activities. Installation considerations include ensuring that the ball valve is suitable for the operating pressure and temperature conditions of the system and that it can withstand exposure to various thermal fluids. Overall, using ball valves can significantly improve control and safety within solar thermal applications while optimizing energy transfer processes.

WHAT MAINTENANCE PRACTICES SHOULD BE FOLLOWED FOR VALVES IN SOLAR SYSTEMS?

Maintenance of valves in solar thermal systems is crucial to ensure their optimal functioning and longevity. Regular inspections should be conducted to check for leaks, signs of corrosion, and proper alignment. Users should also verify that the valves operate smoothly without any resistance. If any issues are detected—such as difficulty in turning or noticeable wear—it is important to address them before they escalate into more significant failures.

Additionally, maintenance practices may involve lubricating moving parts for ball and thermostatic valves, replacing seals, and ensuring that dirt or debris is removed from valve areas. For pressure relief valves, periodic testing and ensuring that they are functioning correctly can prevent catastrophic failures in the system. Incorporating a routine maintenance schedule that considers the specific needs of each type of valve will minimize unexpected downtime and repair costs while maintaining the overall efficiency and reliability of the solar thermal system.

- Incorporating appropriate valve types into solar tube systems significantly influences their efficiency, safety, and performance. Effective management of fluid circulation is accomplished through the use of **1. check valves, 2. ball valves, 3. thermostatic valves, and 4. pressure relief valves, each with distinct functions and advantages. Check valves prevent backflow, maintaining consistent fluid direction, while ball valves facilitate easy flow regulation and quick shut-off. Thermostatic valves dynamically adjust the flow based on temperature, thereby optimizing energy usage, and pressure relief valves safeguard the system against overpressure conditions, ensuring safety during operation.

The selection and maintenance of valves are integral to maximizing the energy efficiency and longevity of solar thermal systems. Proper consideration of factors such as compatibility with thermal fluids, installation technique, and regular maintenance can significantly affect performance outcomes. The intricacies of each valve type and their respective roles mean that careful analysis must be applied when designing and implementing solar thermal systems.

Additionally, the importance of routine maintenance cannot be overstated. Engaging in preventative practices allows users to identify potential issues early, minimizing system downtime and prolonging the lifespan of essential components. By fostering an understanding of the unique roles of different valve types and adhering to best maintenance practices, users can achieve reliable and efficient solar thermal installations while contributing to sustainable energy goals.**

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-valves-are-used-for-solar-tubes/