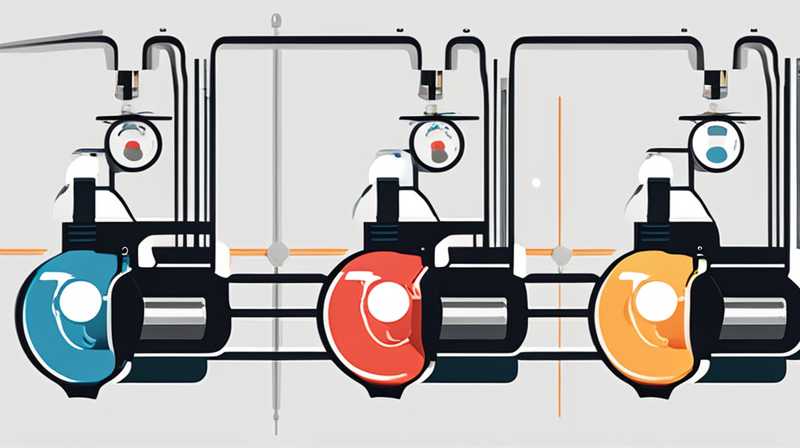

1. Solar manifolds utilize different types of valves, including isolation valves, check valves, and pressure relief valves. Each valve plays a distinct role in maintaining the efficiency and safety of solar thermal systems. 2. Isolation valves allow for maintenance without draining the entire system. This is crucial for the longevity and performance of solar installations. 3. Check valves prevent backflow, ensuring that the fluid circulates properly. They are vital for the optimal functioning of solar thermal applications. 4. Pressure relief valves protect the system from overpressure situations. They are essential for safety, safeguarding the entire system from potential damage due to excessive pressure.

1. ISOLATION VALVES

Isolation valves serve a critical function in solar thermal systems, enabling operators to shut off the flow of fluid without the need to empty the entire system. These components are strategically placed to facilitate easy access for maintenance, repairs, or inspections, thus significantly enhancing the operational efficiency of solar energy installations. The functionality and reliability of isolation valves are paramount in ensuring that any issues can be addressed swiftly without disrupting the entire system.

When selecting isolation valves, several characteristics should be taken into account. Material selection is crucial; options typically include brass, stainless steel, and plastic, each offering different levels of durability and resistance to corrosion. Size and compatibility with the existing plumbing must also be considered to avoid potential leaks and pressure losses. Proper installation and maintenance practices further ensure that isolation valves perform optimally, ultimately extending the lifespan of the solar thermal installation and keeping maintenance costs at bay.

2. CHECK VALVES

Check valves are another essential component in the design of solar manifolds. Their primary function is to allow the flow of a fluid in only one direction, effectively preventing backflow. Backflow can cause significant issues, such as diminished efficiency, potential freezing of fluid during low temperature, and even system damage. The role of check valves becomes even more critical in solar thermal applications, where the fluid’s heat transfer properties must be maintained for optimal energy collection and distribution.

The subtleties of check valve operation can vary depending on their type and design. Spring-loaded and gravity-operated check valves are popular choices, each exhibiting unique opening and closing mechanisms. Furthermore, the construction materials must be resistant to thermal cycling and corrosion. Regular inspection and maintenance are imperative to ensure that these components continue to function correctly, which can prevent costly repairs and replacements. Inadequate performance of check valves can lead to catastrophic system failures to fluid leaks or inefficient heat transfer.

3. PRESSURE RELIEF VALVES

In solar thermal systems, pressure relief valves serve a fundamental safety purpose. These valves are designed to prevent excessive pressure within the system, which can occur due to thermal expansion or operational anomalies. When the pressure exceeds a preset limit, these valves open to release excess fluid, thereby protecting the system’s integrity and ensuring safe operation. This is particularly vital in solar systems, where the riser pipes can heat fluid to high temperatures, causing rapid pressure increases.

Multiple factors influence the proper operation of pressure relief valves. Setting the correct pressure threshold is crucial. If set too high, there may be a risk of pressure build-up, while settings too low can lead to unnecessary rupture or leakage of fluid during normal operation. Regular maintenance checks on the pressure relief valves are necessary to affirm they function accurately and that the seals are intact. Professionals should be consulted for calibrating and testing these components to uphold the safety and efficiency of the entire solar thermal system.

4. ADDITIONAL COMPONENTS

Beyond isolation, check, and pressure relief valves, solar manifolds may also incorporate various additional components that enhance performance and reliability. Flow meters, thermostatic mixing valves, and air vent valves are among these ancillary elements, each contributing unique advantages. Flow meters regulate the fluid’s movement through the system while providing critical data on performance metrics. This data may inform operational adjustments, ensuring that solar energy is harvested as efficiently as possible.

Thermostatic mixing valves play a significant role in optimizing temperature levels in the fluid being circulated. By blending hot and cold fluids, they help maintain ideal operational temperature and prevent overheating. Air vent valves allow for the expelling of entrapped air, which can hinder fluid movement and cause operational inefficiencies. Together, these interconnected components work in harmony to create an effective, comprehensive solar thermal system.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE DIFFERENT TYPES OF VALVES USED IN SOLAR MANIFOLDS?

Solar manifolds employ several valve types: isolation, check, pressure relief, flow control, and thermostatic mixing valves. Isolation valves control the flow, enabling maintenance without draining the system. Check valves prevent backflow, ensuring fluid flows in one direction. Pressure relief valves safeguard against excessive pressure buildup. Flow control valves regulate fluid speed and distribution, enhancing efficiency. Lastly, thermostatic mixing valves adjust fluid temperature to prevent overheating. Each valve type is vital in maintaining optimal performance and safety in solar thermal systems.

HOW OFTEN SHOULD VALVES IN SOLAR MANIFOLDS BE MAINTAINED?

Regular maintenance of valves in solar manifolds is crucial to ensuring optimal performance. A recommended practice is to conduct thorough inspections at least once a year, although systems exposed to extreme weather conditions or frequent usage may require more frequent checks every six months. Essential maintenance tasks include verifying pressure settings, checking for leaks, testing functionality, and cleaning to prevent mineral build-up. Professional assessments are beneficial in identifying those components requiring replacement or adjustment. Proper maintenance ultimately prolongs system lifespan and minimizes potential operational issues.

WHAT HAPPENS IF A VALVE IN A SOLAR MANIFOLD FAILS?

Valve failure in a solar manifold can lead to significant operational challenges, including backflow, pressure build-up, or system leaks. Such issues may result in inefficient heat transfer, leading to inadequate heating of the fluid, which in turn affects overall system efficiency. In severe cases, failure may compromise safety, potentially leading to fluid discharge, increased risks of component damage, or even system shutdown. Comprehensive, proactive maintenance and prompt repairs or replacements are essential in mitigating potential problems arising from valve failure and maintaining optimal operational levels.

SIGNIFICANCE OF VALVES IN SOLAR MANIFOLDS

Understanding the intricate roles that various valves play within solar manifolds is paramount for anyone involved in the maintenance or installation of solar thermal systems. Isolation valves permit necessary access without draining the entire system, while check valves ensure the correct flow and prevent backflow. Pressure relief valves are crucial in safeguarding against potential overpressurization that could threaten the system’s integrity. Without these valves functioning properly, the efficiency and safety of the system may be severely compromised.

The implications of neglecting routine maintenance and the intricacies involved in managing these components cannot be overstated. Expert oversight can translate theoretical knowledge into practical effectiveness, ensuring that solar thermal systems are both safe and efficient. By keeping these systems running optimally, operators can maximize their investment in solar technology, harnessing the sun’s renewable energy in a sustainable and energy-efficient manner.

The world increasingly leans toward renewable energy sources; thus, awareness around the significance of each component in systems like solar manifolds is essential. Whether one is an installer, operator, or consumer, a comprehensive understanding of the various valves used, alongside their individual roles and benefits, can lead to informed decisions, enhanced safety, and greater efficacy in adopting solar technology. Through diligence and focused attention to the integral functions of isolation, check, and pressure relief valves, the promise of solar energy can be realized far beyond mere theory.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-valves-are-used-for-solar-manifolds/