1. The essential valves required for solar separation include: 1) Check valves, which prevent backflow; 2) Shut-off valves, which enable isolation of the system during maintenance; 3) Pressure relief valves, which ensure safety by relieving excess pressure; 4) Flow control valves, which regulate fluid movement within the system. Check valves are crucial because they ensure that fluid flows in one direction, protecting the solar thermal system from damage caused by reverse flow. Their proper installation helps maintain efficiency and prolongs the lifespan of the entire installation.

1. CHECK VALVES

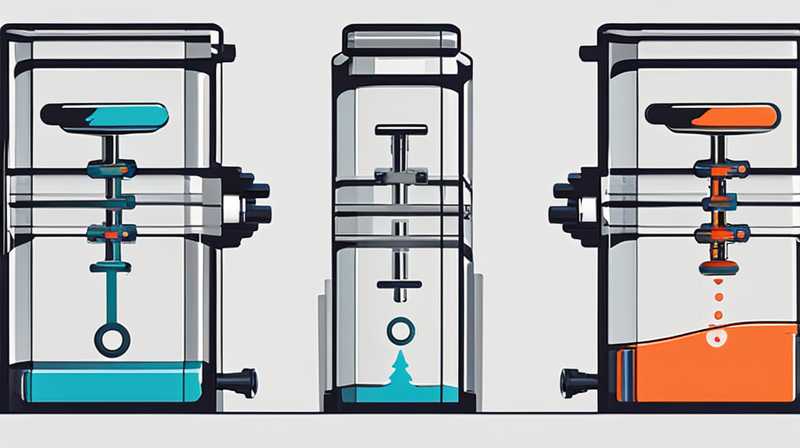

In a solar thermal system where separation is essential, the inclusion of check valves plays a pivotal role. This component serves as a safeguard against backflow, ensuring that the solar fluid travels in the intended direction. The absence of a check valve can lead to complications such as the return of heated fluid, compromising efficiency and potentially damaging the system over time.

The operational integrity of solar collectors hinges significantly on the consistency of fluid movement. Implementing a check valve allows for continuous flow, which maximizes thermal energy capture. Moreover, it minimizes the risk of thermal siphoning, a phenomenon where heat under certain conditions can reverse flow, leading to cooling and inefficiency. A well-placed check valve contributes to a more effective energy transfer in solar heating applications.

2. SHUT-OFF VALVES

Another vital component in solar separation is the shut-off valve. These valves enable technicians or homeowners to isolate specific sections of the solar heating system for maintenance or repairs. The ability to shut off flow without having to drain the entire system is advantageous, allowing for efficient servicing without unnecessary disruptions.

Shut-off valves come in various types, including ball valves and gate valves, each providing specific benefits based on the application within the system. For example, ball valves offer quick operation and reduced pressure drop, while gate valves can handle larger flow capacities. Selecting the appropriate type is significant for ensuring ease of use and maintaining system efficiency, particularly in larger installations. The strategic positioning of shut-off valves not only facilitates maintenance but also enhances safety by ensuring that users can quickly isolate sections in case of emergencies or leaks.

3. PRESSURE RELIEF VALVES

Maintaining optimal pressure levels in a solar thermal system is vital for both efficiency and safety, which underscores the importance of pressure relief valves. These components are crucial for preventing the potential dangers associated with excessive pressure build-up, which can lead to ruptures or system failures. By releasing excess pressure when it exceeds predefined thresholds, these valves safeguard the integrity of the entire system.

The mechanism of a pressure relief valve operates based on a spring-loaded diaphragm or a similar design. When the pressure reaches a certain level, the valve opens, allowing some of the fluid to escape, thus reducing the pressure within the system. This automatic response is essential in scenarios where the solar fluid heats up significantly on sunny days. By controlling pressure dynamically, pressure relief valves help maintain a balance within the system, thereby prolonging the lifespan of solar thermal components while also enhancing safety.

4. FLOW CONTROL VALVES

Flow control valves are instrumental in regulating the movement of fluids within a solar heating system. These valves enable operators to manage the rate at which the solar fluid travels through the pipes, helping to maintain optimal temperatures and improve system efficiency. By adjusting the flow rate, operators can customize the system based on seasonal changes, allowing for greater flexibility in different environmental settings.

In addition to optimizing performance, flow control valves contribute to energy conservation by preventing over-circulation and reducing the workload on pumps. This capability directly correlates with improved energy efficiency, as it minimizes unnecessary energy consumption. Various designs of flow control valves, including proportional control valves and needle valves, can be employed based on specific requirements of the solar thermal system. Ultimately, the inclusion of such valves represents a proactive approach to enhancing performance and ensuring longevity in solar separation systems.

5. ADDITIONAL CONSIDERATIONS IN VALVE SELECTION

While the fundamental valves discussed are essential for effective solar separation, several additional factors must be considered during the selection process. The compatibility of the valve materials with the solar fluid type is paramount, as some fluids may cause corrosion or wear over time. Understanding the chemical properties of the solar fluid helps in selecting valves that will withstand prolonged exposure without failing.

Another crucial aspect involves ensuring that the valves are rated for the appropriate pressure and temperature ranges anticipated within the solar system. Valves that operate effectively under specified conditions help maintain safety and efficiency. Furthermore, it is vital to consider the ease of installation and maintenance when selecting valves, as these attributes can significantly affect long-term operational success.

Sealing mechanisms and design play pivotal roles in effective valve operation. Ensuring that these components have reliable sealing technology guarantees minimal leakage, thus preserving system performance. Valves should be tested for functionality at a range of pressures and temperatures reflective of actual system operations.

6. EMERGING TECHNOLOGIES IN VALVE DESIGN

The market continues to evolve with advancements in valve design and technology, enhancing the options available for solar separation systems. Innovations aimed at improving energy efficiency, durability, and automation are gaining traction. For instance, actuator technology enables greater precision in valve control, allowing for real-time adjustments based on system feedback. The integration of smart technology can lead to automated systems that can optimize flow patterns, enhancing overall energy capture and utilization.

Emerging materials designed to resist corrosion and fatigue are also promising, as they extend the lifespan of valve components, thereby reducing maintenance costs and resource consumption over time. Staying informed about these advancements can help system designers and operators make choices that significantly improve the operational economy of solar thermal systems.

7. MAINTENANCE AND MONITORING STRATEGIES

Beyond the appropriate selection of valves, ongoing maintenance and vigilant monitoring are critical for ensuring lasting performance of solar separation systems. Routine inspections can identify early signs of wear or malfunction within the valve systems before they escalate into larger issues. This proactive approach not only mitigates risks but also enhances operational reliability, making scheduled maintenance an integral part of solar thermal management.

Monitoring technologies, including pressure sensors and flow meters, contribute to better control of the entire system, allowing for timely interventions when parameters deviate from established norms. Effective and consistent utilization of maintenance protocols, coupled with real-time monitoring, ensures that the solar heating system operates at peak performance, safeguarding the investment in renewable energy technology.

8. REGULATORY AND SAFETY STANDARDS

Adhering to local regulations and safety standards is paramount when installing and implementing valves in solar separation systems. Various building codes and industry standards exist to ensure that not only individual components but also entire systems are safe and reliable. Consulting with professionals who understand these regulations can save time and resources and protect against potential liabilities associated with non-compliance.

Furthermore, educational resources are available through industry organizations that can enhance understanding of best practices related to valve selection and installation. Familiarizing with such guidelines promotes the development of safe, efficient solar heating systems.

9. COST CONSIDERATIONS

Budgeting for a solar separation system entails considering not just the initial costs associated with acquiring the necessary valves but also the long-term economic implications of maintenance, efficiency, and energy savings. Investing in high-quality, durable valves may initially seem more expensive, but the accrued savings from reduced maintenance and improved operational efficiency can lead to significant cost savings over time.

Additionally, the cost of downtime due to maintenance issues or system failures should be factored into financial planning. Effective valves contribute extensively to system uptime and reliability, enhancing the return on investment associated with renewable energy systems. Therefore, adopting a comprehensive approach to budgeting can significantly influence the sustainability and profitability of solar thermal installations.

10. FUTURE TRENDS IN VALVE TECHNOLOGY

As solar energy technologies progress, the valves used in these applications will also continue to evolve. The trends toward increasing automation and integration with smart home systems promise to reshape how valves are designed, selected, and operated. New materials being developed aim to offer better resistance to environmental factors, thus extending the lifespan and performance of these components.

Ultimately, staying abreast of technological advancements and emerging trends will empower system designers and operators to make informed decisions, optimize performance, and ensure that their solar separation systems deliver both efficiency and reliability over their intended lifespan.

FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF VALVES ARE MOST COMMONLY USED IN SOLAR SEPARATION SYSTEMS?

The most frequently utilized valves in solar separation systems include check valves, shut-off valves, pressure relief valves, and flow control valves. Check valves are fundamental for preventing backflow, ensuring fluid flows in one direction. Shut-off valves allow for the isolation of portions of the system for maintenance, which is vital for both safety and functionality. Pressure relief valves play a crucial role in safeguarding the system against excessive pressure that can lead to catastrophic failure. Flow control valves are utilized to manage fluid movement, optimizing efficiency and energy use within the solar system. Understanding the roles of these various valve types is essential for effective system design and maintenance.

HOW OFTEN SHOULD VALVES IN A SOLAR SYSTEM BE INSPECTED?

The frequency of inspections for valves in a solar thermal system largely depends on various factors, including system size, type of fluid used, and specific operational conditions. As a best practice, a quarterly inspection is recommended to ensure valves are functioning properly. During these inspections, technicians should examine each valve for signs of wear, leaks, and proper operational mechanics. Should pressure readings or flow measurements indicate irregularities, immediate investigation and potential maintenance would be warranted. Implementing a rigorous inspection protocol ensures timely identification of issues, thereby enhancing the system’s longevity and minimizing downtime. Proactive monitoring contributes significantly to the overall performance and efficiency of solar thermal installations.

WHAT IS THE AVERAGE LIFESPAN OF VALVES USED IN SOLAR SEPARATION SYSTEMS?

The average lifespan of valves utilized in solar separation systems can vary widely based on several factors, such as the environment, type of valve, material quality, and maintenance practices. Typically, high-quality valves may last between 10 to 20 years under optimal conditions, but this can fluctuate based on proper care and operational pressures. Regular maintenance checks help identify any issues early, potentially extending the lifespan of these components. For example, using corrosion-resistant materials and ensuring seals remain intact can significantly reduce wear and tear. Ultimately, investing in quality valves and implementing a proactive maintenance schedule is essential for achieving maximum lifespan and performance from your solar heating system.

Choosing the right valves for solar separation systems is a critical aspect that can ultimately influence the overall efficacy, safety, and longevity of the installation. Understanding the pivotal roles of check valves, shut-off valves, pressure relief valves, and flow control valves lays the groundwork for a robust solar thermal application. Integrating these components with care will ensure that the solar system operates optimally, capturing the maximum amount of energy while minimizing the risk of malfunctions or failures. Furthermore, considering future trends in technology and proactively addressing maintenance will enhance system performance and reliability significantly. By being informed and diligent in every step—from component selection to installation and ongoing monitoring—system designers and operators can capitalize on the transformative capabilities of solar energy, fostering a sustainable future powered by renewable sources. Valves are not merely mechanical components; they are integral to the holistic performance of solar thermal systems. The right valve selection, backed by understanding and adherence to appropriate standards, will enable the successful harnessing of solar energy, thus contributing to a greener, more sustainable world.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-valves-are-needed-for-solar-separation/