1. The appropriate valve for installation on a solar barrel depends on various factors. 2. Considerations include the purpose of the barrel, types of fluids involved, and environmental conditions. 3. Common choices include ball valves for simple flow control and check valves to prevent backflow. 4. For high-temperature solar applications, a rated valve compatible with thermal expansion must be used. A detailed analysis of specific scenarios and valve types provides clarity on making suitable selections.

1. UNDERSTANDING THE SOLAR BARREL CONTEXT

When considering the appropriate valve for a solar barrel, it’s essential to grasp the operational context of this unique system. Solar barrels, typically utilized in solar water heating systems, serve as storage tanks for heated water collected through solar energy. The selection of a valve can significantly impact the efficiency, safety, and longevity of the system, thus emphasizing the need for careful consideration of the type to be installed. Different valves serve various functions, from controlling flow to preventing backflow, making the selection process crucial for optimal performance.

Selecting the right valve involves understanding both the function and the environment in which these systems operate. Solar heating systems often face unique challenges, such as high temperatures and pressures, meaning that the valve chosen must withstand these conditions without compromising efficacy. Moreover, the fluid being stored or transported also plays a role in determining the most suitable valve type. Therefore, a comprehensive understanding of the operational needs of the solar barrel is paramount in ensuring a proper valve installation.

2. VALVE TYPES AND THEIR FUNCTIONS

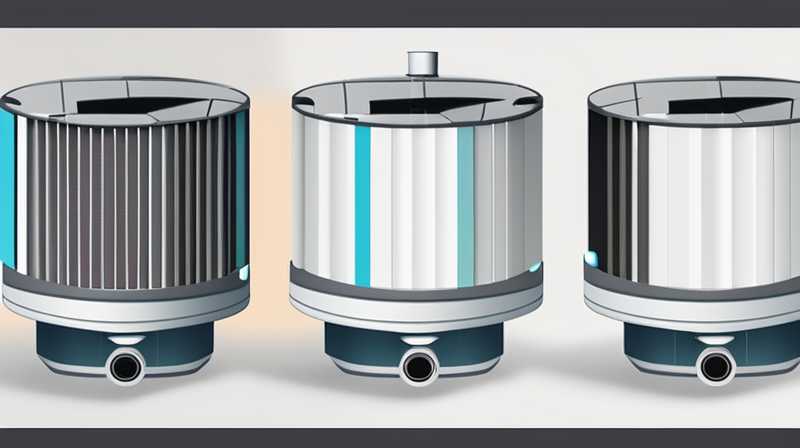

Various types of valves can be employed in solar barrel installations, each designed for specific purposes. Among the most common are ball valves, check valves, gate valves, and globe valves. Understanding the basic functions and advantages of each type can help in making informed decisions.

BALL VALVES

Ball valves feature a spherical disc that functions as a stopcock, allowing for smooth flow control. This type of valve is often favored in solar barrel applications due to its durability and reliability in providing a sealed closure. The quick operation and low friction of these valves enable them to open and close quickly, making them suitable for systems requiring frequent cycling, such as those tied to solar collectors.

Beyond their operational characteristics, the construction materials of ball valves are often resistant to corrosion, especially vital in systems dealing with water that may contain various dissolved minerals. Such resilience ensures a lengthy lifespan, reducing maintenance costs over time while also safeguarding the integrity of the solar water system. Furthermore, ball valves offer adaptability in terms of size and connection types, making them versatile options for diverse installations.

CHECK VALVES

Another essential type of valve commonly associated with solar barrels is the check valve, which primarily serves to prevent backflow within the system. By permitting fluid to flow in only one direction, check valves are vital in maintaining system pressure and preventing potential damage to the solar heating components. Their installation is crucial in scenarios where gravity systems or pump failures might pose risks of reverse fluid movement.

The functioning of check valves can vary; options include spring-loaded, swing, and lever-operated designs, each suitable for different environmental conditions and flow requirements. Utilizing a check valve can help maintain the efficiency of a solar heating system, ensuring that once heated water exits the barrel for use, it does not return to cool the entire system down. As such, installing a properly chosen check valve in a solar barrel not only enhances system safety but also boosts performance.

3. SPECIAL CONSIDERATIONS IN SELECTION

When selecting a valve for installation on a solar barrel, several unique considerations must be acknowledged beyond just function and type. Factors such as temperature and pressure ratings, compatibility with the fluid being transported or stored, and the environmental conditions at the installation site all play crucial roles in determining the most appropriate valve choice.

TEMPERATURE AND PRESSURE RATINGS

Solar heating systems can experience significant temperature fluctuations due to solar input, particularly during peak sunlight hours. Valves used in these systems must possess adequate ratings to withstand both the operational and maximum thermal conditions. Failure to account for temperature limits can lead to leaks, premature wear, or even catastrophic failure of components.

Pressure considerations are equally vital. In a solar barrel, pressure can fluctuate depending on various factors, including water height and heating rates. As such, selecting a valve whose specifications align with these pressure ranges is paramount. Always refer to manufacturer specifications and recommendations to ensure the chosen valve can adequately handle the expected pressures within the system.

FLUID COMPATIBILITY

The type of fluid within the solar barrel also influences valve selection. Most commonly, water is utilized, but systems using antifreeze solutions or other mixtures may necessitate specific valve materials and designs to avoid corrosion or compatibility issues. For example, rubber components within a valve may degrade more rapidly when in contact with certain chemical mixtures.

Material selection becomes essential in ensuring long-lasting performance. Brass, stainless steel, and certain plastics can provide options that resist corrosion and physical damage, allowing for prolonged service lives even under the demanding conditions encountered in solar systems. Careful evaluation of the fluid type will guide the proper selection of materials based on their compatibility.

4. INSTALLATION AND MAINTENANCE TIPS

Ensuring the smooth functioning of valves in a solar barrel is not solely reliant on selection; correct installation and routine maintenance are equally crucial. Taking adequate measures in these areas contributes significantly to the longevity and efficacy of the solar heating system.

INSTALLATION GUIDELINES

Proper installation is the backbone of functionality in any valve system. Specific guidelines exist for each valve type, and it is imperative to follow these to prevent future complications. Careful attention must be paid to the flow direction marked on the valve, ensuring that it aligns with the intended movement of fluids within the system.

Additionally, the sealing methods used during installation, such as Teflon tape or thread sealant, can affect the performance of the valve. Ensuring that all connection points are watertight can prevent leaks which might lead to significant heat loss or system inefficiency. Consulting professional services for installation may often prove beneficial, particularly in complex systems requiring detailed configurations.

ROUTINE MAINTENANCE

Regular checks on valve integrity are necessary to ensure systems continue to work efficiently. Inspect valves for signs of wear, corrosion, or leaks. Early identification of issues allows for timely repairs or replacements, which can save on costly downtime and repairs in the long run.

Maintenance steps should include removing any debris from the valve body and ensuring that the handle operates freely without obstruction. Annual inspections during a slow season are an ideal time to conduct thorough evaluations, thus placing the system in good stead as it enters heavier use periods. Investing time in these maintenance practices can drastically improve the reliability and performance of a solar barrel system.

FREQUENTLY ASKED QUESTIONS

WHAT IS THE PURPOSE OF A VALVE IN A SOLAR BARREL?

Valves in solar barrels serve critical functions related to flow control and system integrity. Primarily, they allow for the management of fluid movement within the solar heating system. By controlling the inflow and outflow of water, valves ensure that heated water is efficiently directed to usage points, while also maintaining pressure within the system. Additionally, backflow prevention mechanisms safeguard against potential operational failures that could lead to significant inefficiencies in the heating process.

Another key aspect of valves is their role in maintenance. During system repairs or modifications, certain valves can be closed to isolate sections of the plumbing, permitting safe work without draining the entire solar barrel. This ability to isolate sections is paramount, especially for systems requiring continuous operation, as it allows for necessary maintenance or troubleshooting without compromising the entire system.

Investing in the correct type and quality of valves is therefore fundamental to both the functioning and safety of solar barrel systems, influencing overall efficiency and longevity.

HOW DOES TEMPERATURE AFFECT THE CHOICE OF VALVE?

Temperature plays a vital role in the selection of valves for use in solar systems due to the extreme conditions these systems often encounter. Traditional valves may not withstand the elevated temperatures generated by solar energy collection, potentially leading to failure or inefficiency. Therefore, the selection of materials with high-temperature ratings becomes crucial for ensuring the ongoing functionality of the system.

For example, plastic valves may become soft and lose their sealing capabilities when exposed to high temperatures, which can occur in solar systems during peak operating times. In contrast, metal valves, particularly those rated for high-temperature applications, are usually more suitable. Selecting materials or design types that can endure these arduous conditions will mitigate the risks of leaks or valve failures, thus preserving the integrity of the entire system.

Consequently, any decision regarding valve installation must incorporate careful analysis of expected temperature ranges, ensuring chosen materials and design types can meet these demands.

WHAT MAINTENANCE SHOULD BE PERFORMED ON SOLAR BARREL VALVES?

Routine maintenance of solar barrel valves is essential for ensuring continued operation and efficiency over time. First, it is crucial to conduct inspections that include examining for leaks, corrosion, or any signs of wear, as early detection is key to preventing larger system failures. Regular checks should include verifying that the valve opens and closes smoothly, and that there are no obstructions hindering its operation.

Cleaning is another vital aspect of valve maintenance. Debris buildup can affect performance, so removing sediment or foreign materials that may accumulate around the valve is important. Additionally, operators should consider periodic manual checks to ensure the valve operates optimally and that seals remain intact. Timely intervention can prevent far-reaching complications in solar heating performance, thus enhancing the reliability of the energy system.

By upholding these maintenance practices, users can prolong the life of valve components within their solar barrel systems, ensuring efficiency and reducing the risk of premature system failures.

The selection and installation of the appropriate valve for a solar barrel are pivotal for ensuring efficiency, safety, and longevity in solar heating systems. A clear understanding of various valve types and their functionalities lays the groundwork for making informed choices tailored to specific operational demands. Factors such as temperature, pressure ratings, and fluid compatibility must be taken into account, as these elements significantly influence both performance and durability.

Proper installation, paired with routine maintenance, enhances the resilience of the solar heating system while mitigating risks associated with valve failure and inefficiencies. Engaging with reputable materials and experienced professionals during installation can provide the necessary support for developing a robust system. Ultimately, focusing on these aspects fosters a greater investment in the overall performance and dependability of solar water heating applications, aligning with sustainable energy goals.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-valve-should-be-installed-on-the-solar-barrel/