To address the issue of repairing a hole in a solar panel, it is recommended to employ 1. specialized adhesive solutions, 2. epoxy-based adhesives, 3. silicone sealants, 4. appropriate patch materials. Each of these choices offers distinct advantages depending on the size and type of damage encountered. Specialized adhesive solutions are engineered specifically for solar panels and can provide the most reliable results.

When it comes to epoxy-based adhesives, they are generally available and provide a robust bond, but they require careful application and curing. For smaller holes or cracks, silicone sealants can effectively prevent moisture ingress and are flexible enough for various conditions. Additionally, choosing the appropriate patch materials based on the solar panel’s construction type can greatly enhance the repair’s effectiveness. These considerations ensure a proper fix that extends the lifespan and efficiency of the solar energy system.

UNDERSTANDING THE REQUIREMENTS FOR REPAIRING SOLAR PANELS

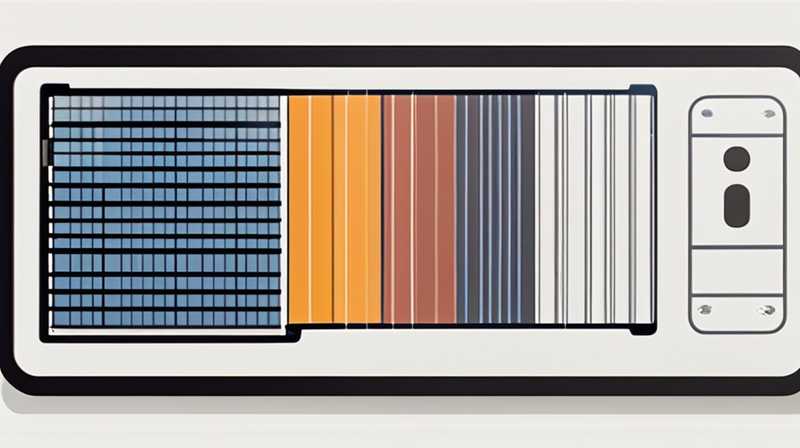

Repairing a solar panel involves several considerations. Initially, one must identify the root cause of the damage and ascertain the extent of the impairment. Understanding the intricacies involved in solar panel technology can illuminate the best methods for effective repairs. In this particular case, a hole can lead to reduced efficiency, potential short circuits, or even moisture infiltration. Thus, a systematic assessment of the damage is crucial before embarking on corrective measures.

The materials chosen for the repair process play a vital role in determining the longevity of the fix. Different adhesives and sealants have varying properties, strength levels, and curing times. Furthermore, the repair method must ensure that it does not void any warranty associated with the solar panel itself. Selecting a repair technique that is safe and compliant with industry standards is essential for maintaining system integrity. Understanding these factors will allow for a comprehensive approach to solar panel repairs.

ADHESIVE TYPES FOR SOLAR PANEL REPAIRS

- SPECIALIZED ADHESIVE SOLUTIONS

Subsequent to identifying the hole or crack in the solar panel, evaluating specialized adhesive solutions becomes paramount. These products are explicitly formulated for solar applications, ensuring optimal performance and durability. They often contain UV-resistant properties that help prevent degradation from sun exposure. Furthermore, they can also cope with temperature fluctuations, ensuring long-term adhesion.

Utilizing specialized adhesives often provides ease of application, as many come in user-friendly packaging with clear instructions. This attribute significantly lowers the risk of improper application, which can lead to further complications. Moreover, the chemistry involved in these adhesives may be designed to work specifically with common solar panel materials, ensuring a strong bond that doesn’t compromise the existing structure. Investing in these adhesives not only guarantees better performance but also prolongs the effectiveness of the panel itself.

- EPOXY-BASED ADHESIVES

Epoxy-based adhesives stand out for their strength and versatility. Formulated from a resin and a hardener, these adhesives create tough bonds that can endure substantial stress and environmental conditions. The primary advantage of epoxy is its ability to fill gaps, making it extraordinarily effective for repairing holes in solar panels. When properly cured, epoxy can transform into a solid, water-resistant substance that significantly enhances the structural integrity of the repair.

However, one must consider the application process, as epoxy requires precise mixing and application within a defined time frame before it begins to cure. Its adhesive properties become activated through an exothermic reaction, leading to its hardening. This quality emphasizes the importance of carefully following instructions to ensure the correct mixture. In addition, epoxy can be sanded and painted once dried, allowing for aesthetic improvements or further protective coatings if necessary.

- SILICONE SEALANTS

Utilizing silicone sealants can serve as a mitigative approach for smaller holes or cracks present in solar panels. Characterized by their flexibility and durability, silicone creates a watertight seal, thus effectively fending off moisture and preventing electrical faults. These qualities make them ideal for scenarios where the damage does not compromise the panel’s overall structural integrity.

In the application phase, silicone exhibits a forgiving nature, allowing for easy manipulation before curing. The straightforward application process often appeals to users who may not be experienced in complex repairs. Moreover, silicone sealants are resistant to high temperatures and adverse weather conditions, ensuring long-term protection in various environments. This resilience, coupled with straightforward application, positions silicone as an attractive option for solar panel repair under specific conditions.

- PATCH MATERIALS

Choosing the appropriate patch materials is vital for effectively sealing the hole and reintegrating the structure of the solar panel. Often made from similar materials as the panels themselves, these patches should blend well to maintain integrity. Transparent patches are beneficial, especially when light transmission is paramount to the panel’s function.

Various manufacturers offer patches that are already adhesive-backed, simplifying the application process. For repairs involving large holes or fractures, a combination of adhesive and patching material may be necessary. This compromise allows the repair to effectively restore the panel’s functionality while ensuring a seamless finish. Selecting the right patch material is essential for ensuring optimal energy production and extending the lifespan of the solar panel.

ENVIRONMENTAL CONSIDERATIONS

- IMPACT OF ENVIRONMENTAL FACTORS

When perhaps contemplating the repair of a solar panel, one must also factor in the environmental conditions that could affect the chosen method. For instance, extreme temperatures can influence adhesive performance, durability, and curing times. Humid conditions or prolonged exposure to moisture can also affect the integrity of certain adhesives, making it imperative to take the locale into account before proceeding.

Different types of adhesives respond differently to environmental conditions. For instance, while silicone sealants offer excellent water resistance, they may not bond exceptionally well under extreme heat. On the other hand, epoxy may harden too quickly in high temperatures, requiring swift application techniques. Engaging with a repair method that recognizes these variables is crucial for achieving a successful outcome.

- LONG-TERM SOLUTIONS

Choosing the right approach can significantly influence energy production in solar panels in the long run. Conventional repair methods might yield short-term fixes but fail to provide comprehensive solutions to recurring issues. Incorporating eco-friendly materials and contemporary best practices can promote longevity and efficiency, ensuring that repairs do not need to be reapplied frequently.

In this context, selecting high-quality adhesives that withstand environmental challenges while retaining performance over time becomes essential. Repairing a solar panel is not just about fixing a defect but also about enhancing its overall capability to generate energy effectively. Considering long-term ramifications results in more sustainable practices and investment.

MAINTAINING SOLAR PANELS AFTER REPAIRS

- REGULAR INSPECTIONS

Post-repair, regularly assessing the solar panel’s condition is essential to ensure the continued efficiency of the repairs implemented. Conducting periodic checks allows for early detection of potential issues that may arise after a repair. This vigilance helps to ensure that future damage can be managed before escalating into more significant problems.

In the context of preventive maintenance, these inspections should include looking for moisture accumulation, cracking, or any signs of adhesive failure. By actively monitoring the performance of repaired panels, individuals can respond promptly to the signs of deterioration or damage. This approach fosters a proactive attitude toward solar panel repair and maintenance.

- PROPER CLEANING AND CARE

Following a repair, proper care assumes greater importance for the lifespan of the panel. Keeping the solar surface clean will not only enhance efficiency but also help prevent new issues from arising. Dust, debris, or grime can impede the function of solar panels, so regular cleaning is an essential part of post-repair care.

The method of cleaning significantly matters as well, particularly around newly repaired areas. It is wise to avoid abrasive materials or harsh chemicals that can degrade adhesives and sealants. Using gentle, approved cleaning solutions in combination with soft cloths can promote the longevity of both the solar panel and the patches or adhesives applied during repair.

COMMON ISSUES RESULTING FROM IMPROPER REPAIRS

- ELECTRICAL MALFUNCTION

Engaging in repair methods that compromise proper adhesive performance can result in unwanted electrical malfunctions. If a hole is not effectively sealed, moisture can infiltrate and damage the solar panel’s internal circuitry. This scenario can lead to costly repairs, increased energy inefficiency, and, in some cases, complete system failure.

Understanding the technical aspects of solar panel construction becomes critical to successfully executing repairs. It is far better to consult professionals rather than risk exacerbating the issues by attempting DIY methods that fail to address fundamental concerns effectively.

- REDUCED EFFICIENCY

Similarly, poor repair techniques can considerably diminish the efficiency of solar panels. If the adhesive bond fails over time, energy production may decrease significantly, impacting overall effectiveness. Such a scenario negates the economic and environmental benefits of installing solar energy systems in the first place.

A comprehensive repair approach that accounts for multiple facets of the solar panel system can mitigate these risks. Understanding the importance of secure, durable, and high-performance repairs ensures that the solar panel continues to function optimally.

FAQS

WHAT MATERIALS WORK BEST FOR REPAIRING A HOLE IN A SOLAR PANEL?

The best materials for repairing holes in solar panels include specialized adhesive solutions, epoxy-based adhesives, silicone sealants, and appropriate patch materials. Specialized adhesive solutions are often formulated for solar applications, ensuring that they are durable and effective. Epoxy-based adhesives provide robust bonding abilities and flexibility, making them suitable for more significant repairs. Silicone sealants serve as effective water barriers, suitable for minor damages while allowing for natural thermal movements. Finally, using patch materials that match the solar panel’s original construction can help maintain the panel’s integrity and efficiency.

HOW CAN I IDENTIFY THE SIZE OF THE DAMAGE ON MY SOLAR PANEL?

Identifying the size and extent of the damage on your solar panel can often be accomplished through visual inspection. Look for noticeable cracks, holes, or discoloration on the surface, as these are clear indicators of potential issues. Additionally, reviewing the system’s performance—through monitoring energy output—can help detect underlying problems. If the energy production appears to decrease significantly, it may hint at undetectable damage. For more detailed inspection, employing tools like infrared thermography can reveal hidden issues such as micro-cracks and inefficient areas that may not be visually apparent. Consulting professionals for complex cases is also a prudent option.

WHAT ARE THE POTENTIAL RISKS OF NOT REPAIRING A SOLAR PANEL HOLE PROMPTLY?

Neglecting to address a hole in a solar panel can lead to several potential risks that could compromise the system’s overall functionality. One major risk is moisture infiltration, which can cause electrical shorts or corrosion, leading to unpredictable system failures. Additionally, environmental factors like dust or debris accumulating in the hole can exacerbate problems, resulting in lower energy production. Over time, even small damages can escalate, leading to more extensive repairs or, in worst-case scenarios, the need for complete panel replacement. Addressing repairs promptly is key to ensuring the longevity and efficiency of the entire solar energy system.

REPAIRING A SOLAR PANEL IS NOT JUST A TEMPORARY FIX; IT HOLDS SIGNIFICANT IMPLICATIONS FOR LONG-TERM FUNCTIONALITY AND EFFICIENCY. The choices made regarding adhesive application, sealant selection, and patch material can dramatically impact energy production, durability, and overall performance. By selecting high-quality materials and methods tailored to the specific context of the damage and operational conditions, individuals can promote sustainable practices that benefit both the environment and their energy costs.

It is crucial to maintain a proactive approach, ensuring that periodic inspections and proper maintenance are integrated into the solar panel’s lifecycle. By fostering this habit, one can avoid unexpected system failures, maximize efficiency, and prolong the lifespan of the solar panel installation. Engaging with professional services for significant repairs or ongoing challenges can also offer peace of mind and specialized knowledge that may be lacking in the DIY realm. When approached with care and consideration, repairing holes in solar panels can become an effective endeavor, safeguarding the integrity and productivity of renewable energy systems into the future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-to-use-to-glue-the-hole-in-the-solar-panel/