If the solar valve cannot be turned, several steps can be taken to diagnose and potentially resolve the issue. 1. Assess the physical condition of the valve and surrounding components, 2. Investigate any blockage or debris that may be obstructing movement, 3. Consider the possibility of mechanical failure or wear, and 4. Consult the manufacturer’s guidelines or seek professional assistance if needed. A thorough examination of the valve’s physical state is crucial; any signs of rust, corrosion, or mechanical obstruction can impede functionality and might require immediate repair or replacement to ensure efficient operation of the solar heating system.

1. UNDERSTANDING SOLAR VALVES

Solar valves play a pivotal role in managing the flow of heat transfer fluids in solar thermal systems. Their primary function is to control the direction of this fluid, ensuring that heat collected from sunlight is efficiently transferred to the storage tanks or the heating systems. This process is essential for optimizing the system’s performance and maintaining the desired temperature levels.

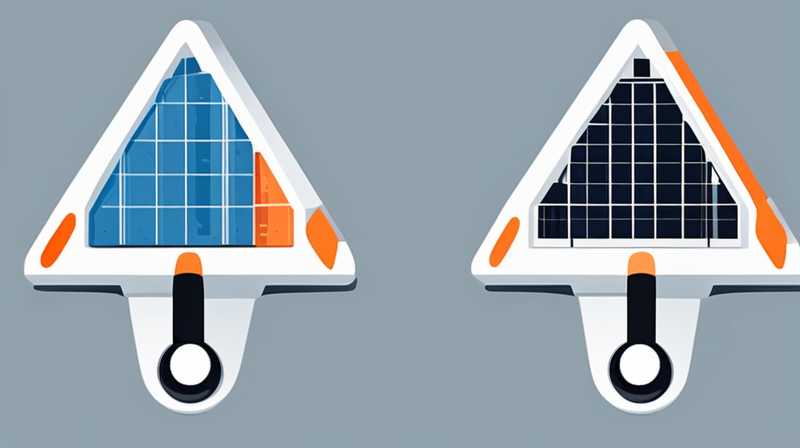

The operation of solar valves involves both manual and automatic control mechanisms. Mechanical components like springs and levers may be included in manual systems, while automatic valves rely on sensors that detect temperature and flow rates. Understanding the operational principles and these components is integral to troubleshooting any operational failures.

Proper attention must be given to valve maintenance. Without routine inspections and necessary repairs, the system’s overall efficiency can drastically decrease, leading to unexpectedly high energy costs and potential damage to the equipment. Regular assessments will help identify early signs of wear and tear that may hinder the valve’s functionality.

2. COMMON CAUSES FOR VALVE MALFUNCTIONS

A variety of factors can contribute to the difficulties encountered when attempting to turn a solar valve. Blockages, mechanical failures, and external influences are three main categories of issues that could impede the valve’s operation. Each cause necessitates a systematic approach to identification and remediation.

BLOCKAGES AND DEBRIS

Physical blockages are often the most immediate concern when a valve cannot be turned. Debris, sediment, or other residues can accumulate around valves due to the continual circulation of heat transfer fluids, especially if the system has not been properly maintained. This accumulation can create enough resistance to inhibit valve movement.

When examining for blockages, it is important to inspect not only the valve itself but also the surrounding pipes and connectors. Common culprits include mineral deposits from hard water, rust particles from aging pipes, and organic materials. Cleaning these elements may restore full functionality.

MECHANICAL FAILURES

In some cases, mechanical failures within the valve itself may be responsible for its inability to turn. Wear and tear on internal components, such as seals and bearings, can lead to a complete breakdown of the valve, making it impossible to operate. Over time, fluctuations in pressure and temperature may exacerbate these issues, leading to deformations or breakage in critical components.

To mitigate mechanical failure, it is recommended to conduct periodic evaluations of the valve’s internal mechanisms. If wear is detected, timely replacements or repairs can prevent more substantial issues down the line. Ignoring these signs may lead to costly repairs or the need for a full valve replacement, which could have been avoided with proper care.

3. TROUBLESHOOTING STEPS

When faced with a solar valve that won’t turn, a structured approach to troubleshooting is essential. This methodical process includes visual inspections, functional assessments, and consultations with expert resources when necessary.

VISUAL INSPECTIONS

Initiate the troubleshooting process with a thorough visual inspection of the valve and its immediate environment. Look for visible signs of corrosion, rust, and structural integrity. In some cases, the issue may lie in the mounting bracket or the connection to the piping. Over time, vibrations and temperature fluctuation can compromise these components.

Checking for leaks around the valve is also critical. A leak can indicate that the valve seal is failing, which may necessitate either repair or replacement. Pay attention to whether the valve handle or actuator appears misaligned, as mechanical misalignment can also prevent turning.

FUNCTIONAL ASSESSMENTS

Once the visual checks are complete, conduct functional tests to assess the mechanical operation of the valve. Attempt to apply gentle pressure to the valve handle to gauge responsiveness. If there is no movement, further inspection is warranted. It is vital to ensure that any attempt to force the valve open does not result in damage, as excessive force can crack or break internal parts.

Consider the possibility of a stuck actuator. Some solar systems utilize electric or pneumatic actuators, which can fail due to power loss or internal faults. Checking the power supply, as well as confirming that control signals are appropriately transmitted, may be necessary if the valve is electronically controlled. These logical steps will help in narrowing down the problem area.

4. PREVENTIVE MEASURES

Preventive strategies can extend the lifespan and enhance the efficiency of solar valves. Developing a comprehensive maintenance plan with regular intervals for inspection, cleaning, and required replacements is essential to maintain optimal performance.

ROUTINE MAINTENANCE PRACTICES

Implementing systematic maintenance practices is one of the most effective ways to minimize malfunction risks. This includes inspecting the valve and associated components for signs of wear, corrosion, and blockages at least once a year. Flush the system to remove settled debris and monitor the fluid quality, as poor-quality fluids can contribute to degradation over time.

Regular lubrication of mechanical parts within the valve can also prevent seizure and enhance operability. Utilizing high-quality lubricants suitable for the operational environment will ensure that the concerned components move freely, extending their functionality significantly.

EDUCATION AND TRAINING

Raising awareness among personnel responsible for operating and maintaining solar heating systems is crucial. Providing comprehensive training on how to recognize early signs of valve malfunctions will empower users to take precautionary action before significant failures arise. With knowledge of the system’s trouble-spots, operators can respond quickly to any issues and implement corrective actions.

Proactive engagement and education will ultimately contribute to the overall reliability and efficiency of the solar heating system, creating a more sustainable energy solution.

5. WHEN TO SEEK PROFESSIONAL ASSISTANCE

Despite best efforts, there may be scenarios where professional intervention becomes necessary. Complex mechanical failures, an identified gas leak, and systematic electrical issues indicate potential concerns that exceed individual competence. Recognizing when to call a professional can save both time and money in the long run.

COMPLEX MECHANICAL FAILURES

If following a series of troubleshooting steps does not yield any results or if the problem is identified but beyond your capability to remedy, engaging a professional service provider is an advisable course of action. They will have specialized knowledge, tools, and techniques to handle difficult repairs, and extensive experience with various solar valve models ensures they can act swiftly and accurately.

Such experts can conduct an in-depth analysis to determine the root of the operational failures, provide recommendations for parts that need replacement, and guarantee that any repairs made will adhere to industry standards.

IDENTIFIED LEAKS OR ELECTRICAL ISSUES

In cases where leaks are suspected or if issues persist that relate to the solar system’s electrical components, do not attempt to resolve these problems independently. Safety should be a priority, and specialized skills are requisite in executing such repairs efficiently. Seeking a trained technician will ensure that the system operates safely and minimizes the risk of damage to the equipment or the property.

FREQUENTLY ASKED QUESTIONS

WHAT KIND OF MAINTENANCE DOES A SOLAR VALVE REQUIRE?

Regular maintenance for a solar valve is essential to ensure it operates effectively. Yearly inspections should be conducted to check for any signs of rust, wear, or blockage. Keeping the valve clean and free of debris encourages smooth operation. Furthermore, lubricating moving parts can prevent mechanical failure. If any unusual noises or irregularities are detected during operation, further investigation is warranted immediately. Timely maintenance helps extend the life of the valve and enhance the overall efficiency of the solar heating system.

HOW CAN I TELL IF MY SOLAR VALVE IS STUCK OR BROKEN?

Determining whether a solar valve is stuck or malfunctioning involves a few steps. First, check if any physical obstructions or debris are preventing movement. Attempt to turn the valve gently; if it resists and there are no visible blockages, mechanical failure is likely. Listening for grinding or unusual noises can also provide insight into a possible internal problem. If issues persist after troubleshooting, it may be time to consult a professional. These experts can accurately diagnose the problem and recommend appropriate next steps.

IS IT SAFE TO ATTEMPT REPAIRS MYSELF?

While some minor repairs may be manageable for experienced individuals, safety is paramount. Many valves involve pressurized systems, which can be dangerous if mishandled. If encountering complex mechanical failures or electrical issues, enlisting professional assistance is highly recommended. Trained technicians have the expertise and tools necessary to navigate potential risks and ensure the correct repairs are made. Always prioritize safety and the integrity of the solar heating system when considering repairs.

In summation, addressing the challenges posed by a solar valve that cannot be turned requires a methodical approach encompassing careful inspection, functional assessments, and timely interventions. Engaging in routine maintenance practices significantly enhances the longevity and performance of solar thermal systems. Identifying root causes and applying corrective measures fosters a reliable energy solution that leverages renewable resources efficiently. Should individuals encounter persistent issues beyond their expertise, reaching out to professionals is imperative to ensure safety and effectiveness. Ultimately, by blending personal vigilance with professional resources, one can maximize the benefits derived from solar technologies.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-to-do-if-the-solar-valve-cannot-be-turned/