If a solar tube is non-standard, it’s essential to address the issue promptly to ensure optimal performance and longevity. 1. Assess the specifications, 2. Consult the manufacturer, 3. Consider modification options, 4. Seek professional assistance. Understanding the specific discrepancies is paramount. For instance, if the diameter or length deviates from accepted norms, the efficiency of solar light capture may diminish, leading to inadequate illumination indoors. Furthermore, consulting with the manufacturer can provide clarity on warranty coverage or alternatives, ensuring that any adjustments made do not void existing guarantees. Exploring modification options might also allow for seamless integration, depending on the material and structure of the installation site. Lastly, involving professionals can help navigate complex installations or repairs, especially if the issue stems from installation errors. This multi-faceted approach can effectively restore functionality and performance to the solar tube system, maximizing its potential benefits.

1. UNDERSTANDING NON-STANDARD SOLAR TUBES

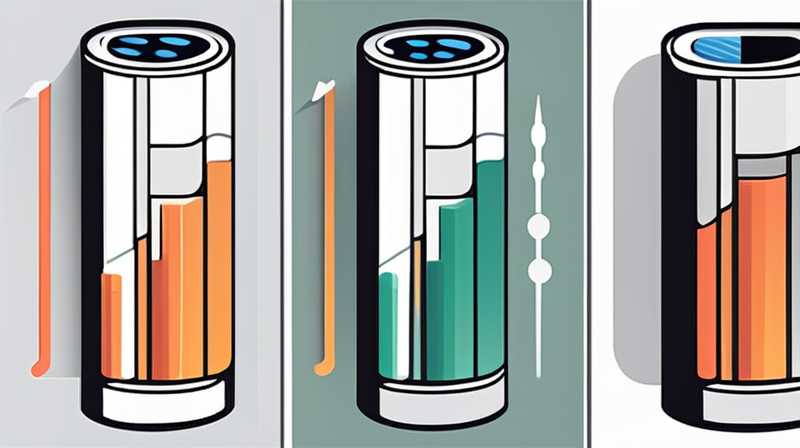

Solar tubes are designed to harness sunlight and direct it into living spaces, offering an energy-efficient alternative to traditional electric lighting. However, challenges arise when these tubes do not conform to established measurements or specifications, referred to as non-standard solar tubes. Such variations can stem from manufacturing defects, inaccurate measurements during installation, or improper selection based on the needs of the space.

Understanding the implications of a non-standard solar tube is crucial. When a solar tube does not meet industry standards, it may lead to inadequate sunlight capture. This inefficiency can result in poor indoor lighting conditions, which subsequently affects overall ambiance and productivity within a space. Moreover, installations that do not comply with specifications can lead to unnecessary costs associated with repairs or replacements. Recognizing these challenges emphasizes the importance of addressing discrepancies immediately to restore effective functionality.

2. EVALUATING THE SPECIFICATIONS

In order to effectively resolve the issue of a non-standard solar tube, a detailed evaluation of its specifications is imperative. First, a comprehensive review of the installation guidelines must be undertaken. These guidelines typically provide specific dimensions, angles, and materials needed for proper solar tube operation. By comparing the actual measurements against these benchmarks, one can identify areas of deviation. For example, if the diameter of the tube is smaller than recommended, light transmission could be severely compromised.

Second, identifying the intended application of the solar tube can guide the assessment process. Different environments—residential spaces, commercial establishments, or industrial settings—may demand distinct specifications for optimal performance. In a residential context, a solar tube may need to channel light into a living room effectively, while in a commercial setting, it might serve a different purpose. Each application necessitates careful consideration of the tube’s design and orientation to ensure maximum light capture and distribution.

3. ENGAGING WITH THE MANUFACTURER

After assessing the solar tube’s specifications, the next logical step involves engaging with the manufacturer. This engagement can unlock vital information about the product and its warranty. Manufacturers might provide valuable insights into whether the non-standard aspects are due to production flaws or if they stem from the installation process. Furthermore, understanding whether the tube is still under warranty is critical, as it can save time and expenses in resolving the issue. Should the product be deemed defective, manufacturers may offer replacements or provide guidance on rectifying the situation.

Additionally, communication with the manufacturer allows for clarification of product guidelines. Asking specific questions about installation methods, operational standards, or acceptable tolerances can ensure that any further actions align with official recommendations. This knowledge not only helps to correct the current problem but also serves as a precaution for future installations or replacements.

4. CONSIDERING MODIFICATION OPTIONS

In certain instances, the non-standard attributes of a solar tube might not be easily rectified through exchanges or warranties. As such, exploring modification options becomes a viable solution. One potential approach is to use adapters or extensions that can be customized to fit the existing tube. Such accessories can compensate for size discrepancies, allowing for improved light capture without necessitating a full replacement of the solar tube system. Moreover, modifications can often be performed without extensive renovations to the existing structures.

Another avenue for modification involves altering the installation angle or positioning of the solar tube. Adjusting the angle at which the tube is installed can enhance solar absorption, particularly if it helps align with optimal sunlight exposure throughout different times of the year. While performing these modifications, care must be taken to ensure that structural integrity and safety are not compromised during the adjustment process.

5. SEEKING PROFESSIONAL ASSISTANCE

Engaging with professionals for non-standard solar tube issues is a highly prudent choice, particularly when technical expertise is required. Experts in solar installations possess the requisite understanding of specialized tools and equipment. Their experience not only ensures that repairs or replacements are carried out correctly but also minimizes the risk of future complications. Professionals can conduct a thorough assessment, pinpoint failures, and devise solutions tailored to individual circumstances.

Additionally, professional assistance is invaluable for individuals who may lack familiarity with solar technology. In some cases, attempting adjustments without adequate knowledge may lead to improper installations or potential hazards. Professionals can guide through the complexities of solar installations, ensuring compliance with safety protocols and regulatory standards. The investment in professional services can ultimately lead to longer-lasting solutions, optimizing the solar tube system’s performance over time.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE COMMON CAUSES OF NON-STANDARD SOLAR TUBES?

There are several reasons for the emergence of non-standard solar tubes. Manufacturing defects might be one potential cause. In instances where production processes do not meet quality control standards, the dimensions or functionalities of solar tubes can be compromised. Additionally, inaccurate measurements taken during installation can lead to improper fitting, resulting in inconsistencies. Environmental factors, such as changes in temperature or structural modifications to the building, can also contribute to misalignment or physical deformation of the tube over time.

Other causes might stem from incorrect selection of solar tube types based on the specific needs of a building. For example, using a model not designed for particular weather conditions or geographical areas may result in failure to meet lighting expectations.

HOW CAN A NON-STANDARD SOLAR TUBE AFFECT ENERGY EFFICIENCY?

A non-standard solar tube can significantly impede energy efficiency within a building. When these tubes do not conform to appropriate specifications, the capture of solar light may be unnecessarily reduced. As a result, occupants are compelled to resort to artificial lighting, thereby increasing electricity consumption. This contradiction undermines the primary purpose of solar tubes—namely, to reduce reliance on traditional energy sources.

Furthermore, if a solar tube is unable to disperse light effectively, it may lead to an uneven distribution throughout the area, resulting in dark spots and other inefficiencies. Consequently, the overall impact on energy costs can be profound, negating any potential savings promised by the use of solar technology.

WHAT STEPS SHOULD BE TAKEN IF MODIFICATIONS ARE REQUIRED?

If modifications are deemed necessary, several important steps should be followed to ensure a smooth process. Initially, a thorough evaluation of the existing solar tube system is required to ascertain the extent of modification needed. This assessment should involve measuring dimensions, analyzing angles, and reviewing installed components to identify areas for adjustment.

Subsequently, the involvement of qualified professionals can facilitate the process, ensuring modifications adhere to industry standards and are performed safely. If applicable, acquiring necessary materials such as adapters or extensions should occur next. Finally, implementing the modifications should proceed with caution, ensuring that all structural elements remain intact, and thorough testing of the system follows to confirm optimal performance.

If a solar tube is non-standard, immediate action is essential to mitigate negative impacts. Analyzing specifications, consulting with manufacturers, exploring modification avenues, and enlisting professional help creates a comprehensive framework to restore functionality and efficiency. By addressing these issues proactively, it is possible to transform a non-standard solar tube into a valuable asset for any building, serving its intended purpose of effective light transmission and enhancing energy efficiency. The benefits of utilizing properly functioning solar tubes extend beyond mere illumination; they enhance living spaces, reduce electricity costs, and contribute to broader sustainability goals.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-to-do-if-the-solar-tube-is-non-standard/