What to do if the solar thermal insulation bucket is broken?

1. Ensure immediate assessment of the damage, 2. Check for leaks or cracks, 3. Evaluate repair options, 4. Consider replacement if necessary. If the solar thermal insulation bucket is broken, prompt action can mitigate further damage and restore functionality. A thorough inspection is essential; begin by identifying the nature of the damage: this includes looking for visible cracks, assessing insulation effectiveness, and checking for any resulting leaks. These inspections help determine the proper steps to address the issue. If repair is feasible, utilize appropriate materials suited for such repairs; however, if the damage is extensive or the bucket is significantly compromised, opting for a new unit may be the most efficient course of action for long-term use.

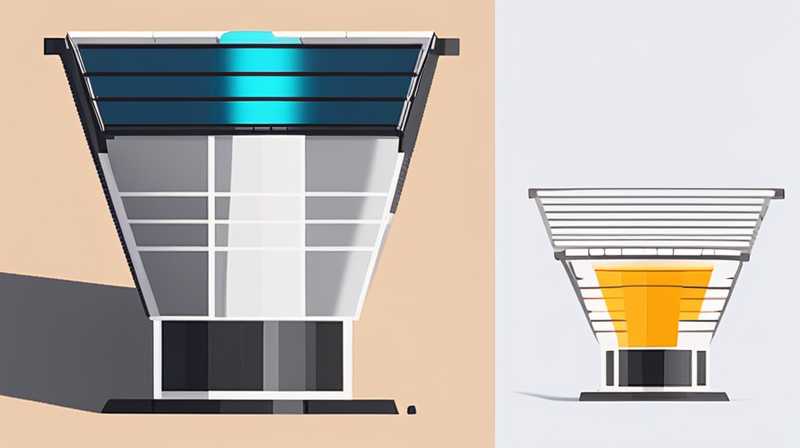

1. UNDERSTANDING SOLAR THERMAL INSULATION BUCKETS

Solar thermal insulation buckets are integral components in solar energy systems. They function by storing heated water, acting as a buffer between solar collectors and the distribution system. The necessity for these buckets stems from their ability to maintain temperature while minimizing heat loss. Understanding how they operate is vital for effective maintenance and troubleshooting when issues arise.

The construction of these buckets often involves robust materials designed to withstand high temperatures and pressure. However, various factors such as weather conditions, mechanical wear, and installation errors can lead to damage. Recognizing potential points of failure requires both technical knowledge and vigilant observation. Enhanced material composition and innovative designs are continuously evolving to improve longevity and efficiency, making it crucial for owners to stay informed about advancements in the field.

2. IDENTIFYING DAMAGE IN THE BUFFER SYSTEM

A broken solar thermal insulation bucket can present a host of problems, primarily associated with leaks and loss of insulation properties. Upon identifying an issue, the first task is to conduct a thorough examination of the component. One should look for visible signs of damage, including bulging, cracking, and leaks. These indicators are often straightforward but may sometimes require intricate detection methods to unveil hidden issues.

The underlying reasons for such damage can vary. Environmental factors, such as temperature extremes or exposure to harsh weather conditions, can play a significant role in the deterioration of bucket materials. Additionally, improper installation or maintenance routines may contribute to failure points. Thus, a careful evaluation of the installation process and maintenance protocols is essential for understanding how to prevent future occurrences.

3. REPAIR OPTIONS FOR SOLAR THERMAL INSULATION BUCKETS

Once damage is recognized, a concise plan of action is necessary. Should repairs appear viable, numerous materials and techniques can be employed to restore the insulation bucket. For minor cracks or small leaks, utilizing specialized sealants or adhesives may prove effective in ensuring the integrity of the system. It is vital to select products that can withstand high temperatures and are compatible with the bucket’s material.

In addition to sealants, reinforcing the damaged areas with additional layers of insulation can enhance the bucket’s performance post-repair. This process requires careful application to avoid compromising the effectiveness of the insulation. Conversely, if a repair is deemed impractical due to the extent of the damage, considering a complete replacement of the insulation bucket may be the most prudent decision. Selecting a higher-quality replacement unit might be an opportunity to upgrade the system’s overall effectiveness.

4. PERFORMING A REPLACEMENT

When opting for a replacement, it is imperative to choose the right size and specifications to match the existing system. Investigating alternative products on the market can lead to discovering improved options that may enhance efficiency. During the selection process, considerations such as energy efficiency, material durability, and compatibility with your current setup are fundamental.

Furthermore, ensure proper installation follows the guidelines provided by manufacturers. Inadequate installation can lead to further issues, so investing time and resources into this stage is crucial. Whenever possible, enlist professionals who are experienced in solar thermal systems. Their expertise can save time and resources in the long run, ensuring that the new insulation bucket is correctly fitted and operates as intended.

5. MAINTENANCE TO PREVENT FUTURE ISSUES

Once a repair or replacement has been implemented, emphasizing routine maintenance cannot be overstated. Regular inspections can aid in the early identification of potential issues before they develop into serious problems. Observing how the insulation bucket performs over time offers insights into its longevity and effectiveness.

Additionally, maintaining the entire solar thermal system, including solar collectors and pumps, contributes to the overall performance and lifespan of the insulation bucket. Implementing best practices in maintenance helps ensure sustained efficiency and minimizes the risk of future failures. Staying proactive in these areas not only preserves functionality but also enhances the energy output and savings provided by solar thermal systems.

6. ENVIRONMENTAL IMPACT AND SUSTAINABILITY

The functioning of solar thermal insulation buckets relates closely to the broader context of environmental sustainability. By efficiently collecting and retaining solar energy, these systems play a crucial role in reducing reliance on fossil fuels. A breakdown in system components can undermine these environmental benefits, making it essential to prioritize repairs or replacements.

Additionally, choosing sustainable and reliable materials for replacements can further decrease the ecological footprint of the setup. As innovation continues in the field of renewable energy, integrating green technologies and resources will be critical for fostering environmental stewardship. The commitment to efficient energy solutions not only benefits individual households but also contributes to global efforts in mitigating climate change.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE SIGNS OF A BROKEN SOLAR THERMAL INSULATION BUCKET?

The signs indicating a broken solar thermal insulation bucket can vary depending on the nature and extent of the damage. Generally, one might observe visible cracks or leaks, which are the most straightforward indicators of trouble. Additionally, one may experience a decrease in heating efficiency, which might manifest as lower water temperatures despite adequate sunlight exposure. A broken insulation bucket can lead to increased heat loss, so if there’s a noticeable rise in energy consumption without any change in usage patterns, that could also point to a malfunction. Furthermore, inspect for bulging or warping of the bucket material, as this can indicate internal pressure build-up or material fatigue. If any of these signs are present, immediate attention is recommended to assess the situation properly.

HOW CAN I REPAIR A SOLAR THERMAL INSULATION BUCKET?

Repairing a solar thermal insulation bucket requires careful assessment and the use of appropriate materials. For minor cracks, specialized sealants designed to withstand high temperatures can be applied. Begin by cleaning the damaged area to remove any debris, grease, or moisture. After preparing the surface, apply the sealant according to the manufacturer’s instructions. If the damage is more extensive, reinforcement with additional insulation materials may be necessary to restore optimal performance. In some cases, using fiberglass mats for reinforcement can be beneficial. If repairs seem impractical or the damage is significant, replacing the entire unit may be the best option to ensure reliable operation.

WHEN SHOULD I CONSIDER REPLACING A BROKEN INSULATION BUCKET?

Replacement should be considered when the damage to the solar thermal insulation bucket is beyond simple repairs or when the integrity of the system is compromised. If the bucket has significant cracking, extensive leaks, or material degradation, trying to repair it could result in further issues down the line. Assess the cost of repairs versus the investment in a new unit; if repairs are frequent or costly, it may be more economical to opt for replacement. Additionally, purchasing a newer model that boasts improved features, enhanced durability, and greater energy efficiency could yield better long-term benefits compared to continually repairing an aging unit.

In summary, if the solar thermal insulation bucket is broken, various steps can be taken to address the situation effectively. Regular inspections and maintenance can significantly reduce the likelihood of severe damage. A thorough evaluation will typically involve assessing the extent of the damage, exploring repair options, or considering a replacement when necessary. Furthermore, adopting sustainable practices and high-quality materials contributes not only to the efficiency of solar thermal systems but also to broader environmental initiatives. Ensuring that all components operate optimally ultimately aids in the efficient harnessing of renewable energy, which is essential for both households and the planet.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-to-do-if-the-solar-thermal-insulation-bucket-is-broken/