1. A solar solenoid valve can produce noise due to several factors, with potential solutions including: 1) ensuring proper installation, 2) checking for debris or obstructions, 3) adjusting pressure settings, and 4) evaluating the electrical connections. A prevalent cause of the noise stems from mechanical issues or air in the line, which can affect the valve’s operation. Addressing these concerns promptly ensures optimal functionality and prolongs the system’s lifespan.

1. UNDERSTANDING SOLENOID VALVE FUNCTIONALITY

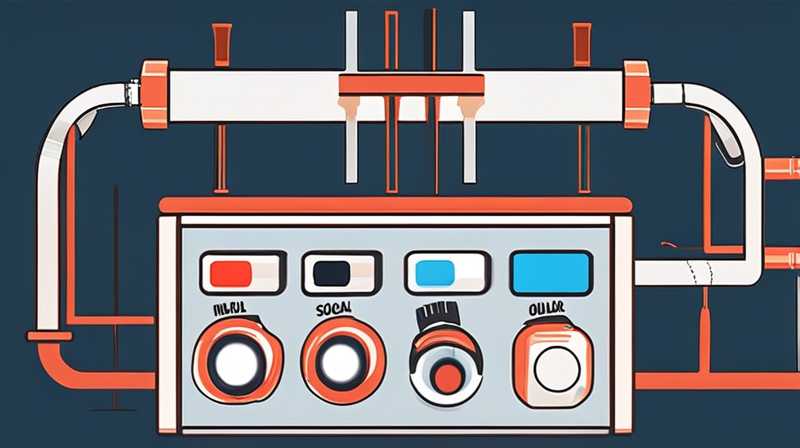

A solar solenoid valve is an essential component in many solar irrigation and heating systems. It operates by controlling the flow of water or fluid through the system using an electromagnetic mechanism. The solenoid consists of a coil that generates a magnetic field when electricity flows through it. This magnetic field then actuates a plunger that opens or closes the valve, allowing or preventing the passage of fluid.

When these valves function correctly, they are typically silent. However, various factors can lead to noise production, which often indicates underlying issues. Understanding the solenoid valve’s operation is vital in troubleshooting noise problems effectively. The sound may be a simple indication of mechanical malfunction or improper installation.

2. MECHANICAL ISSUES LEADING TO NOISE

Mechanical issues are often at the heart of noise problems in solar solenoid valves. Components such as the plunger and spring may wear out over time, leading to abnormal sounds when the valve operates. Additionally, if the valve is not securely mounted, it may vibrate or rattle during operation, producing annoying noise.

The plunger within the solenoid must move freely without obstruction. Dust, dirt, or mineral buildup can impede its motion. Regular maintenance, including cleaning the valve housing and inspecting all moving parts, is essential for ensuring the smooth operation of the valve. Neglecting these aspects can exacerbate noise and lead to more significant failures.

3. THE IMPACT OF AIR IN THE LINE

Air trapped within the fluid line of a solar system can also contribute to noise emanating from the solenoid valve. When air is present, it may create pressure fluctuations as fluid flows, leading to a chattering sound as the plunger opens and closes irregularly. This condition not only produces noise but also affects the efficiency of the entire system.

To resolve this issue, it’s necessary to bleed the system. Bleeding involves releasing trapped air through specific valves until water flows steadily, removing all air pockets. Ensuring that your system is completely filled with fluid will eliminate air-related noise and enhance overall performance.

4. WORN OR DAMAGED COMPONENTS

Over time, wear and tear can lead to damaged components within the solenoid valve. Common issues include corrosion, which can occur in harsh environments or with poor-quality materials. Corrosion compromises the integrity of the valve, resulting in unusual noises during operation.

If components are worn or damaged, replacing them is crucial rather than attempting temporary fixes. Investing in high-quality replacement parts ensures durability and reliability, reducing the likelihood of future noise complaints.

5. ADJUSTING PRESSURE SETTINGS

Improper pressure settings can lead to excessive noise during valve operation. If the pressure is too high, it can cause the solenoid to strain, creating vibrations and rattling sounds. Conversely, if the pressure is too low, it may prevent the valve from opening completely, which can also lead to noise as the solenoid struggles to function correctly.

Adjusting the pressure to the recommended settings outlined by the manufacturer can mitigate these issues. Regularly checking and calibrating pressure gauges will ensure that the system operates efficiently, reducing both noise and risk of mechanical failure.

6. EVALUATING ELECTRICAL CONNECTIONS

Electrical connections play a pivotal role in a solar system’s operation. Loose or corroded electrical connections can create poor conductivity, resulting in noise as the solenoid struggles to receive adequate power. It is crucial to regularly inspect and maintain all electrical components associated with the valve.

Ensuring that all connectors are clean, tight, and free from corrosion will support optimal solenoid function and reduce unnecessary noise. If electrical issues persist, consulting a qualified technician may be the best approach to resolve complex electrical concerns.

7. REGULAR MAINTENANCE PRACTICES

Implementing a scheduled maintenance routine is vital for the longevity of a solar solenoid valve. Regular inspections allow for the identification of potential issues before they evolve into significant problems that result in noise or system failure. Aspects to include in a maintenance schedule consist of checking for debris, inspecting electrical connections, and evaluating pressure settings.

Furthermore, it is recommended to conduct periodic cleaning of the solenoid valve to remove any buildup that might hinder performance. Employing a thorough maintenance strategy is essential for sustaining the efficiency of the solar system while curtailing noise-related disturbances.

FREQUENTLY ASKED QUESTIONS

WHAT CAUSES A SOLENOID VALVE TO MAKE NOISE?

Various factors contribute to noise production in a solenoid valve. The most common issues include mechanical malfunctions, air trapped in the fluid line, improper pressure settings, and worn or damaged components. Regular maintenance and inspection practices can help pinpoint specific causes of noise.

HOW CAN I SILENCE A NOISY SOLENOID VALVE?

To silence a noisy solenoid valve, it is essential to first identify the underlying issue causing the noise. This may involve ensuring proper installation, cleaning debris, adjusting pressure settings appropriately, and checking electrical connections. If these steps do not resolve the noise, replacing damaged components may be necessary.

IS NOISE FROM A SOLENOID VALVE A SIGN OF A SERIOUS PROBLEM?

While noise from a solenoid valve does not always indicate a severe problem, it is a warning sign that should not be ignored. Ignoring these noises can lead to more significant issues within the system, such as complete valve failure. Addressing the source of the noise promptly will help maintain the efficiency and longevity of the system.

Addressing noise produced by a solar solenoid valve is critical for ensuring optimal performance and longevity of the system. By identifying issues such as mechanical failures, air in the system, improper settings, or electrical problems, one can effectively mitigate disturbances. Furthermore, implementing a routine maintenance schedule minimizes the risk of encountering noise-related issues while enhancing overall efficiency. The importance of proper installation and the use of quality materials cannot be overstated. It is equally vital to replace worn or damaged components promptly. Recognizing that regular checks on system pressure and connections can substantially reduce operational noise levels is essential. As noise can indicate a myriad of issues, diligence in monitoring the system is indispensable. Ultimately, a proactive approach towards maintenance and timely addressing of concerns will not only resolve noise problems but also extend the life of the solar solenoid valve and the entire system. Taking these necessary steps ensures a quieter and more efficient solar setup, contributing positively to sustainable energy solutions.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-to-do-if-the-solar-solenoid-valve-makes-a-noise/