To address the situation where a solar solenoid valve is closed, several actions can be taken to diagnose and resolve the issue effectively. 1. Check the power supply, examine the wiring, assess the control signal, review the manual. 2. Inspect for blockages or damage, verify the installation location. 3. Test the solenoid functionality, consider replacement solutions, consult with professionals. 4. Maintain regular checks, document issues for future reference, and install monitoring systems if necessary. In cases where the valve remains closed despite troubleshooting, it may imply deeper systemic issues or component failure that warrants a comprehensive inspection from qualified personnel. Proper understanding and intervention are essential to ensure optimal operation and safety of the solar system.

1. UNDERSTANDING SOLENOID VALVES AND THEIR FUNCTIONALITY

Solar solenoid valves play a crucial role in controlling the flow of liquid or gas in solar thermal systems. These electrically operated valves are essential for regulating the transfer of heat transfer fluids to and from the solar collectors and storage tanks. Their primary function involves opening or closing based on an electrical signal, allowing or preventing the flow of fluid.

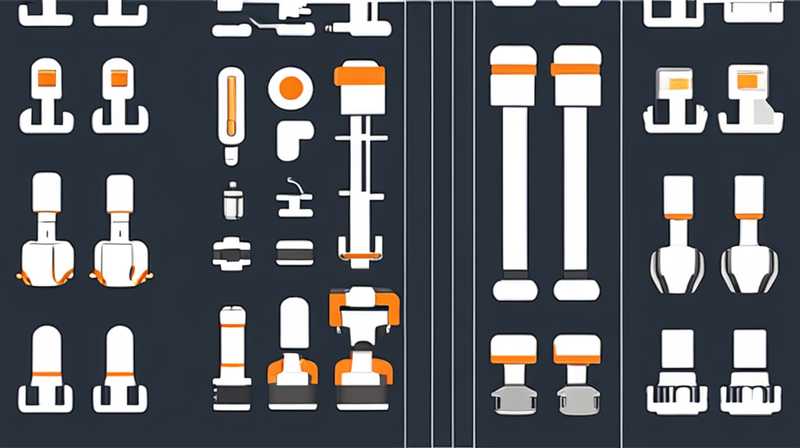

Understanding the operation mechanics of these valves is paramount for effective troubleshooting. A typical solenoid valve consists of a coil, a plunger, and a spring mechanism. When electricity flows through the coil, it generates a magnetic field that moves the plunger to open or close the valve. Should the solenoid valve become closed unexpectedly, it can disrupt the entire operation of the solar heating system, potentially leading to inefficiencies or even system failure.

2. TROUBLESHOOTING A CLOSED SOLENOID VALVE

In addressing a closed solar solenoid valve, several preliminary investigations are critical. First, check the power supply. This entails ensuring that the valve is receiving the correct voltage and that there are no interruptions in power. A simple multimeter can help in measuring voltage levels across the terminals. If the power is consistent, the next step involves inspecting the wiring. Frayed or disconnected wires may prevent the solenoid from operating.

The control signal, which tells the solenoid whether to open or close, must also be examined. Issues arise when the signal does not reach the valve effectively. It is advisable to follow the wiring diagram of the system to trace where the signal might get lost. If electrical components are functioning, the system settings or programming must be reviewed to ensure parameters are correctly set to activate the valve.

3. PHYSICAL INSPECTION OF THE VALVE AND SURROUNDING EQUIPMENT

In addition to electrical checks, a physical inspection of the solenoid valve itself is essential. This involves looking for any visible blockages or damage that could impede the solenoid’s function. Sediments and debris can accumulate in the valve and piping, especially in systems not regularly maintained. Flushing the system can help eliminate these blockages, restoring normal operation.

Furthermore, inspecting the installation location of the solenoid can reveal factors that may affect its operation, such as temperature extremes or exposure to moisture. Valves located in areas with significant temperature variations might experience thermal expansion or contraction that impacts functionality.

4. FUNCTIONALITY TESTS OF THE SOLENOID VALVE

If all preliminary checks do not yield solutions, testing the solenoid functionality becomes necessary. This involves disconnecting the solenoid from the system and applying direct power to see if it opens when energized. A malfunctioning valve may require cleaning, repairs, or complete replacement.

In scenarios where repairs are inadequate, considering replacement solutions is prudent. When purchasing a new solenoid valve, ensure it matches the system’s specifications regarding voltage, capacity, and material compatibility. Consulting with professionals who are experienced in solar thermal systems can also provide tailored advice and recommendations for suitable replacements.

5. MAINTENANCE AND FUTURE PREVENTION STRATEGIES

To prevent future occurrences of solenoid valve closure, regular maintenance practices should be established. This can include scheduled inspections, cleaning valves, and checking system components for wear and damage. Keeping a log or document detailing the system’s performances and any anomalies can be invaluable for troubleshooting subsequent issues.

Adding monitoring systems that provide real-time feedback on the operation of the solenoid valve and other integral components can enhance proactive management. This not only ensures optimal performance but also assists in early identification of potential issues, thereby extending the lifespan of the entire solar heating system.

6. IMPORTANCE OF PROFESSIONAL CONSULTATION

In complex cases or where repeated issues arise, seeking the assistance of qualified professionals can provide significant benefits. Expert technicians can offer comprehensive system health assessments and troubleshooting methods that may not be apparent to the layperson. They have the necessary tools, knowledge, and experience to diagnose intricate problems accurately and provide effective solutions. Collaborating with professionals includes adherence to safety protocols and can ultimately save both time and financial resources in repairs.

FAQs

WHAT SIGNS INDICATE A SOLENOID VALVE IS CLOSED?

Several indicators can suggest that a solar solenoid valve has closed. One primary sign is the noticeable drop in performance or efficiency of the solar heating system. Heated fluid not reaching the storage tank can often be traced back to a closed valve. Additionally, checking the flow rates can be helpful; if the expected flow is significantly reduced or nonexistent, this could imply that the valve is shut.

Other physical indicators include unusual sounds from the system, such as clunking or vibrations that occur intermittently, suggesting that the valve is trying to operate but is becoming stuck. In certain systems, local indicators or alerts can be present, indicating reduced performance or system faults.

Lastly, monitoring the temperature of the fluid can reveal issues. If the fluid does not reach anticipated temperatures due to the valve’s closure, it can point directly to the obstruction. Regular analysis and monitoring can become a beneficial approach in early detection.

CAN A SOLENOID VALVE BE REPAIRED OR DOES IT NEED REPLACING?

Whether a solenoid valve can be repaired or necessitates replacement depends on the specific condition of the valve and the extent of the damage incurred. Often, minor issues such as debris accumulation can be resolved with cleaning, while electrical faults might be managed through simple repairs. The repair process entails assessing the valve’s components to identify any that may be worn, damaged, or broken.

If the coil is damaged and unable to create the magnetic field necessary for operation, replacement might be a more feasible option. However, replacement should be considered if the valve shows signs of severe wear, corrosion, or if fundamental components are compromised beyond repair.

In instances where repeated faulting occurs after repairs, replacement becomes the advisable course of action to ensure system reliability. Choosing a high-quality replacement valve that matches the system’s specifications will also contribute to long-term functionality.

HOW OFTEN SHOULD SOLENOID VALVES BE CHECKED?

Regular maintenance and checks on solenoid valves are essential for ensuring optimal performance in solar systems. Ideally, conducting system inspections should occur at least once a year, especially before the start of the solar season. Seasonal checkups allow technicians to identify and remedy potential issues before they manifest into more significant problems.

In addition to annual inspections, signs of performance decline or abnormal operations should prompt immediate evaluations. When the system experiences fluctuations or irregularities in temperature or flow rates, checking solenoid valves (and other components) becomes necessary. Further, any environmental factors that may affect the system, such as exposure to extreme weather or changes in operational schedule, also merit more frequent checks.

FINAL THOUGHTS ON SOLAR SOLENOID VALVE MANAGEMENT

Addressing a closed solar solenoid valve involves a systematic approach that delves into both electrical and physical considerations. Engagement with multiple troubleshooting methods will yield the best chances of restoring functionality effectively. Through diligent checks of power supplies, wiring integrity, control signals, and the valve’s physical state, many issues can be diagnosed and resolved.

Starting with foundational checks enables building a robust understanding of the valve’s role within the larger solar system. Ongoing inspections combined with routine maintenance practices create a sustainable environment for optimal solar heating operations.

Moreover, investing in monitoring equipment and collaborating with experienced professionals can provide an additional layer of assurance for system efficiency and longevity. Utilizing these strategies ensures that any potential complications can be addressed promptly, minimizing downtime and maintaining the functional integrity of solar energy systems for years to come. The implications of failing to maintain or respond to valve issues can lead to significant energy losses and unnecessary financial expenditures, highlighting the necessity of proactive management.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-to-do-if-the-solar-solenoid-valve-is-closed/