If the solar main valve is broken, you must address it promptly to prevent issues such as system inefficiencies, leaks, or complete failures. 1. Assess the situation, 2. Identify the type of valve, 3. Shut down the system, 4. Replace the valve with a compatible model. One essential point is to ensure that proper shutdown procedures are followed before any inspection or replacement occurs. This will safeguard both personnel and system integrity. After completing these actions, consider consulting a licensed professional for further assistance or to perform the installation.

1. UNDERSTANDING THE SOLAR MAIN VALVE

An essential component of any solar heating system, the solar main valve regulates the flow of fluid through the system. This regulation is crucial for maximizing efficiency and ensuring that heated fluid reaches various parts of the system without unnecessary loss. The valve typically operates under a range of temperature and pressure conditions, which means materials and design must accommodate these extremes.

Understanding the implications of a malfunctioning valve is critical not only for performance but also for the longevity of the entire system. A broken valve can result in leaks, causing energy loss and requiring additional resources to maintain function. Furthermore, ingraining knowledge about the valve’s role can prepare owners for better maintenance practices and quicker diagnostics, which is vital for minimizing downtime and financial impacts.

2. IDENTIFYING SYMPTOMS OF A BROKEN VALVE

Several symptoms indicate that the solar main valve may be malfunctioning. Visual inspections are an excellent starting point; signs of corrosion, rust, or pooling water around the valve area should raise alarms. Unexpected system behavior is another indicator; instances of fluctuating temperatures or diminished heat distribution can signal a problem with valve integrity.

Another common symptom involves noise. Hissing, banging, or other unusual sounds may resonate from the system, which can suggest air entrapment or mechanical failure. Understanding these symptoms enables quicker reaction times—failure to act can lead to escalated issues that require more extensive repair work and monetary investment. Identifying these symptoms and addressing them promptly can save both time and resources in the long run.

3. INITIAL ASSESSMENT AND SAFETY PROTOCOLS

Upon discovering that the solar main valve is broken, the first step is conducting an initial assessment of the situation. Always prioritize safety; ensure the system is powered down before proceeding with any inspections. This mitigates risks associated with hot fluid or pressurized lines. Personal protective equipment (PPE) should be worn, including gloves and safety goggles, to safeguard against possible injuries during inspection or maintenance tasks.

Documentation of the system’s existing state is also crucial. Take notes on the observed symptoms, as well as any unusual characteristics noted during inspections. Doing so ensures clarity when consulting with professionals and guides effective decision-making throughout the repair or replacement process. The meticulous approach to both safety and documentation lays a solid foundation for addressing the main issues surrounding the broken valve.

4. VALVE TYPES AND THEIR SIGNIFICANCE

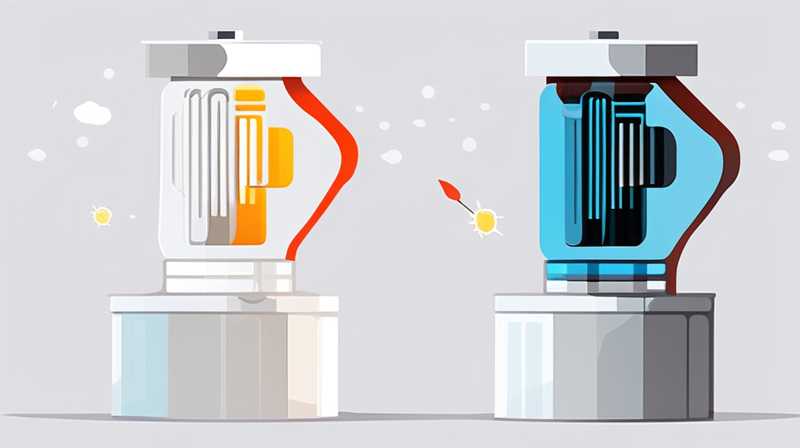

Understanding the specifics of different valve types is integral to determining the appropriate course of action. Most solar heating systems use either manual or automatic valves. Manual valves offer direct control and are often simpler in design, making them easier to repair but may require more frequent user intervention. On the other hand, automatic valves utilize sensors and actuators to adjust flow based on system needs, ensuring efficiency but introducing complexity in repair tasks.

Focusing on the valve type is crucial for compatibility during replacement. Utilizing a mismatched valve can lead to additional complications, including inefficiencies and potential damage to the system. Therefore, engaging with official specifications and seeking out parts from reputable suppliers is vital to aligning with manufacturer standards and ensuring that the long-term viability of the system remains intact.

5. PROCEDURES FOR SHUTTING DOWN THE SOLAR SYSTEM

When preparing to address a faulty solar main valve, following appropriate shutdown procedures is paramount. Start by turning off the pump and any connected electrical systems to prevent accidental activation. It’s vital to allow the system to cool down, as end-of-cycle operation could result in scalding fluids that pose significant risks during maintenance.

While the system is cooling, ensure hydraulic pressure is relieved. This can often be achieved by opening bleed valves located on various system components. This critical step not only improves safety but also makes it easier to access the valve and perform necessary replacements. Proceeding with utmost diligence ensures that the subsequent tasks can be executed without complications or safety hazards.

6. REPLACING THE BROKEN VALVE

Upon concluding the initial procedures, begin the actual valve replacement process. Carefully detach the existing valve, being cautious to retain any necessary fittings or seals that may be reused. Inspect surrounding tubing and joints for signs of wear or failure; it is often wise to replace these components while addressing the valve issue to prevent future breakdowns.

Before installing the new valve, confirm its compatibility with the existing system by cross-referencing specifications. Follow manufacturer guidelines to ensure the proper orientation and positioning of the valve, as incorrect installation can lead to further inefficiencies or failure of the system. Tighten all connections adequately to avoid leaks post-installation. Once the new valve is securely fitted, proceed to gradually restore power and operational readiness to the solar system, meticulously monitoring for any irregularities during the resumption phase.

7. PROFESSIONAL ASSISTANCE AND CONSULTATION

While DIY measures can address minor valve issues, consulting professionals is often advised for more comprehensive repairs. Certified technicians bring valuable expertise and experience to the table, ensuring that replacements are executed effectively and in accordance with safety regulations. Qualified specialists will also conduct thorough inspections, identifying oft-overlooked issues that may arise within the solar system.

To ensure optimal performance and longevity of the solar heating system, establishing a relationship with knowledgeable professionals is highly beneficial. Regular check-ups and maintenance can prevent future breakdowns, promoting the system’s efficiency and safeguarding against costly repairs. Engaging with professionals ensures that all actions are performed according to industry standards, which can prolong the lifespan and operational effectiveness of the solar system.

8. ROUTINE MAINTENANCE AND FOLLOW-UP

Maintaining a solar heating system involves routine checks to prevent valve and system failures. Regular inspections of the solar main valve—checking for signs of wear, accumulated dirt, or leaks—should be incorporated into maintenance schedules. It is also wise to inspect other system components, including pumps and hydraulic lines, to ensure overall performance remains at optimal levels.

Documentation of maintenance sessions is crucial; recording observations and actions taken provides a roadmap for future maintenance efforts. If issues arise with the valve or other system components, having historical data assists technicians in efficiently diagnosing problems and prolonging the system’s life. Emphasizing proactive maintenance and being mindful of the valve’s significance can prevent more severe issues from developing and ensure a consistently efficient heating system.

FREQUENTLY ASKED QUESTIONS

WHAT IS THE AVERAGE LIFESPAN OF A SOLAR MAIN VALVE?

The average lifespan of a solar main valve varies based on material quality and environmental conditions, typically ranging from 10 to 15 years. Regular maintenance impacts longevity; neglecting routine inspections can lead to premature wear and malfunction. Harsh environmental conditions can accelerate the degradation process, affecting both the valve’s performance and the system at large.

Choosing high-grade materials during installation can also enhance durability; stainless steel or specially coated valves can withstand extreme temperatures and pressures better than standard ones. Moreover, engaging professional assistance for maintenance can contribute to the valve’s extended service life; identifying early signs of wear can lead to timely repairs or replacements before severe issues manifest.

HOW CAN I IDENTIFY AN AUTOMATIC SOLAR VALVE?

Identifying an automatic solar valve involves checking its operational mechanics. Typically, these valves feature electronic actuators that respond to various thermal or pressure cues from the system. Visual indicators may include sensors or wiring attached to the valve body, which facilitate communication between the valve and the control system.

Consulting manufacturer documentation can also provide detailed visual aids and specifications. Many automatic valves are designed with labeling for easy identification; checking these labels can reveal valuable information about valve type, model number, and operational guidelines. In case of uncertainty, a consultation with a professional can clarify valve characteristics and assist in identification, ensuring suitable replacements or repairs.

HOW OFTEN SHOULD I CHECK MY SOLAR SYSTEM VALVE?

Regular checks of the solar system valve are essential for optimal performance, and conducting inspections at least twice a year is advisable. Seasonal changes can impact valve functionality, making periodic assessments necessary to ensure that all components are operating as intended. More frequent checks should be implemented during extreme weather events or after substantial maintenance work.

Documenting the condition of the valve during each inspection is beneficial. Keeping track of observable wear, unusual noises, or other symptoms ensures timely intervention when required. Emphasizing regular evaluations of the valve can mitigate risks of system failure and promote efficient operation, ensuring the solar heating system continues to meet energy needs effectively.

In summary, addressing a broken solar main valve involves various critical steps that ensure not only immediate resolution but also long-term system sustainability. Starting with a thorough assessment and shutting down the system is paramount to prevent further complications and hazards. It is essential to understand the valve’s operational significance, as this knowledge will lead to informed decision-making and effective repairs. Selecting the right replacement parts, coupled with professional consultation, can provide invaluable support in maintaining system efficiency and safety. Finally, establishing a routine maintenance plan incorporating regular valve checks fosters a proactive approach to system health, ensuring longevity, efficiency, and minimal operational interruptions.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-to-do-if-the-solar-main-valve-is-broken/