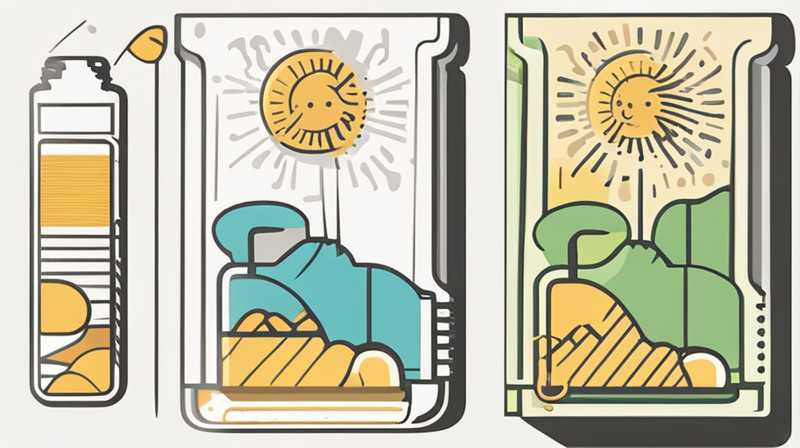

If solar glue has been scratched, immediate attention is necessary to prevent further damage. 1. Assess the extent of the scratching, 2. Gather appropriate materials for repair, 3. Clean the affected area thoroughly, 4. Apply the necessary repair solution. Each point is critical to ensure the solar panel’s integrity and overall performance is maintained. The scratches can lead to decreased efficiency and durability if not addressed promptly.

1: UNDERSTANDING SOLAR GLUE

Solar glue, often referred to as encapsulant, is a vital component in solar panel construction. Its primary purpose is to adhere solar cells to protective glass and backing materials, ensuring durability and efficiency. The composition of solar glue typically includes ethylene-vinyl acetate (EVA), known for its clarity and UV resistance. When scratches appear on solar glue, they can compromise both the cosmetic appearance and functional capabilities of the solar panel.

The impact of a scratch can vary considerably depending on its depth and location. Shallow scratches may not pose immediate threats, while deeper abrasions can lead to moisture ingress, which is detrimental to the electrical components housed within the panel. It’s essential to evaluate the situation calmly and effectively to determine the best course of action to remedy the scratch issue.

2: EVALUATING THE DAMAGE

Before any remedial steps can be taken, a thorough evaluation of the scratches present must occur. Careful inspection can be conducted either visually or with the aid of magnification tools. This initial assessment will help ascertain whether the scratches are superficial or if they penetrate deeper, potentially affecting the integrity of the solar panel.

Identifying the depth of the scratches requires a keen eye. A shallow scratch may only mar the surface and can sometimes be polished out or covered. However, an examination should also focus on potential accompanying issues, such as delamination or the presence of moisture. This ensures comprehensive damage assessment, setting a solid foundation for the repair process.

3: GATHERING REPAIR MATERIALS

Once the extent of the scratches has been ascertained, it is crucial to gather appropriate repair materials. Choosing the right products will significantly influence the outcome of the repair effort. For minor surface scratches, materials such as polishing agents or solar panel repair kits could suffice. For more severe damage, procuring professional-grade solar adhesive or sealant may be necessary.

Understanding the specifications and application of these materials is paramount. For instance, high-quality EVA adhesive should be chosen for its compatibility with solar modules. When compiled correctly, the resources will allow for effective correction of the scratched areas, thereby maintaining the solar panels’ functionality.

4: CLEANING THE AFFECTED AREA

Proper cleaning of the scratched region is absolutely vital before initiating any repairs. Utilizing a soft cloth and a suitable cleaning solution, such as a non-abrasive soap, will help eliminate any grease, dirt, or dust particles that could interfere with adhesion. It’s essential to avoid any harsh chemicals that could further damage the solar glue or the surrounding components.

After the initial cleaning, a second round with distilled water ensures all residues are removed. Drying should be done gently with a microfiber cloth to avoid additional scratches during the cleaning phase. Ensuring the surface is entirely clean and dry will create optimal conditions for the application of repair materials, significantly enhancing the probability of a successful fix.

5: APPLYING THE REPAIR SOLUTION

The actual repair process begins once the preparation is successfully completed. For superficial scratches, a careful application of polishing agents may suffice. These agents can often fill in minor imperfections, restoring clarity and appearance to the glue. A consistent and judicious application will help in blending the repair with the original material.

For deeper scratches requiring adhesive, applying a thin layer of the chosen sealant through the use of a small applicator ensures precise delivery. Allowing sufficient curing time as described in the product instructions is imperative. This step not only solidifies the repair but can also enhance the glue’s longevity, providing an extra layer of protection against environmental factors.

6: MONITORING THE REPAIRED AREA

After the repair has been completed, diligent monitoring is critical to ensuring long-term success. A regular check of the repaired section will help ascertain whether proper adhesion is maintained. It’s also advisable to observe any changes that might indicate the presence of moisture or air bubbles.

Implementing a maintenance schedule for the solar panels will aid in recognizing potential issues before they escalate. Keeping track of the repaired area aids in preserving overall panel efficacy and mitigating future complications, ultimately optimizing solar energy production over time.

FAQs

WHAT CAUSES SCRATCHES ON SOLAR GLUE?

Scratches on solar glue can result from several factors, including environmental impacts, improper handling during installation, or routine maintenance procedures. Environmental wear, such as hail or debris from storms, may contribute to surface damage. Furthermore, human error during maintenance can exacerbate the likelihood of scratches, particularly if tools or cleaning methods are not handled with care. Regular inspections of solar panels can help spot scratches early and mitigate further damage.

HOW LONG DOES IT TAKE FOR THE REPAIR TO CURE?

The curing time for repairs using solar adhesives or sealing agents can vary based on the specific product used and the environmental conditions. Typically, repair adhesives may take from 24 hours to several days to achieve their full strength. Factors such as temperature, humidity, and airflow can influence this timeline. It is crucial to follow the manufacturer’s guidelines concerning curing to ensure optimal adherence and effectiveness.

CAN SCRATCHES IMPACT SOLAR PANEL PERFORMANCE?

Yes, scratches can significantly affect solar panel performance. Even minor scratches can cause light refraction issues, resulting in reduced energy output. More serious scratches may allow moisture to penetrate, leading to potential electrical failures or a decrease in overall panel efficiency. Ensuring that any scratches are promptly addressed is essential for maintaining the panels’ operational integrity and maximizing energy production.

Addressing scratches on solar glue is a task that requires immediate attention to prevent long-term damage. Evaluating the scratch’s extent provides insight into the appropriate remedial actions. Collecting quality repair materials lays the groundwork for a successful fix, while thorough cleaning of the affected area ensures optimal adhesion during the process. A careful application of repair solutions and diligent monitoring post-repair will help restore the solar panel’s functionality. Moreover, understanding the implications of scratches on performance underscores the importance of maintenance and proactive intervention. By adhering to these practices, solar panel owners can significantly extend the lifespan and efficiency of their energy systems, ultimately leading to greater sustainability and cost savings.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-to-do-if-the-solar-glue-is-scratched/