In energy storage stations, 1. power resistors, 2. wirewound resistors, 3. thick-film resistors, and 4. high-frequency resistors are utilized to manage and dissipate energy effectively. Power resistors are designed for high voltage and current levels, providing stability and reliability in such setups. Among these, wirewound resistors stand out due to their ability to sustain high temperatures and adaptable resistance values, making them ideal for energy conversion processes. In addition, thick-film resistors are noted for their compact size and efficient performance in printed circuit boards (PCBs) that facilitate energy regulation tasks. Furthermore, high-frequency resistors are essential for devices operating at rapid frequencies where precision is key. Each of these types serves a unique role in enhancing the efficiency and reliability of energy storage systems.

1. UNDERSTANDING POWER RESISTORS IN ENERGY STORAGE

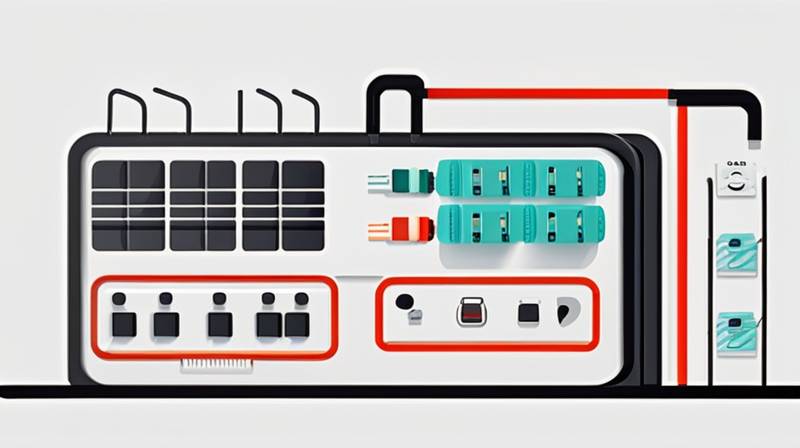

Power resistors are integral components in energy storage stations, designed to handle substantial electrical loads while conserving energy and ensuring operational safety. These resistors help dissipate excess energy as heat, preventing damage to electronic components and maintaining system stability. A vital aspect of power resistors is their capability to manage high voltages and resistive contexts effectively, assuming a pivotal role in various applications within energy storage systems.

It is important to comprehend that power resistors come in different configurations, including fixed and variable types, catering to diverse operational requirements. Fixed resistors maintain a stable resistance value throughout their lifespan, while variable options allow for adjustments to suit changing loads. Their design employs materials like ceramic coatings and aluminum, ensuring robustness in response to thermal stress and varying environmental conditions. Such reliable operation of power resistors is critical in ensuring that energy storage systems function correctly and efficiently, reinforcing their significance in modern energy solutions.

2. WIREWOUND RESISTORS AND THEIR APPLICATIONS

Wirewound resistors are a specialized class of resistors that utilize a wire, typically made from nichrome or another high-resistance alloy, wound around an insulating core. This design allows for a high tolerance to both thermal stress and electrical load, making wirewound resistors highly desirable in energy storage applications. Their ability to sustain operational efficiency at elevated temperatures ensures that they can be used in various environments without compromising functionality.

Furthermore, the precision of wirewound resistors makes them essential in applications requiring accurate calibration and measurement. Engineers and designers appreciate their stable performance characteristics, which is crucial when managing resources in energy storage stations. Their adaptability to different power ratings permits incorporation into various systems, ensuring that they can meet specific energy demands. The ability to customize their resistance levels and power ratings based on project requirements further enhances their appeal in the development and optimization of energy storage systems.

3. THICK-FILM RESISTORS IN ENERGY STORAGE SYSTEMS

Thick-film resistors have emerged as a popular choice for energy storage utilization due to their unique fabrication process and performance benefits. These resistors are manufactured by screen-printing a composite of conductive and insulating materials onto a substrate, which creates a film with predictable resistance properties. Such technology results in resistors that occupy less space and exhibit precise resistance values even under varying environmental conditions.

The compact form factor of thick-film resistors makes them ideal for integration into printed circuit boards (PCBs), which are commonly used in energy management systems. Their high reliability and efficiency enable them to play a significant role in energy monitoring and control applications. Moreover, advancements in thick-film technology continue to enhance their performance characteristics, increasing resistance to temperature fluctuations and improving their overall durability. This ongoing evolution has made thick-film resistors an essential component in contemporary energy systems.

4. HIGH-FREQUENCY RESISTORS

High-frequency resistors are specifically engineered to operate effectively in circuits subjected to elevated frequencies. In energy storage applications, where rapid response times are often crucial, these resistors serve multiple functions, from signal amplification to providing load to circuits. Their low parasitic capacitance and inductance characteristics are fundamental to maintaining signal integrity in high-frequency environments, ensuring that performance remains uncompromised.

The performance of high-frequency resistors is markedly affected by their design processes, which often involve high-quality materials and precision manufacturing techniques. These resistors are essential in applications such as energy monitoring systems, where rapid data collection and processing are required. Their ability to minimize signal distortion ensures accurate readings of energy levels and efficient management of stored resources. The focus on advancing high-frequency technology continues to shape how energy storage systems function, enabling more sophisticated tools for energy management.

FAQs

WHAT MATERIALS ARE USED FOR POWER RESISTORS?

Power resistors consist of various materials tailored for specific functions and durability. Typically, they comprise metal film or ceramic elements, which provide excellent thermal conductivity and resistance to electrical loads. Metal provides superior heat dissipation, while ceramics offer insulation properties that prevent electrical failures. Additionally, the type of wire used in wirewound resistors is often made from alloys such as nichrome or copper, selected for their stable resistance characteristics. Coatings of aluminum oxide may be applied for extra insulation. By strategically combining these materials, engineers ensure that power resistors deliver consistent performance within energy storage systems.

HOW DO WIREWOUND RESISTORS COMPARE TO OTHER RESISTOR TYPES?

Wirewound resistors exhibit distinct advantages over alternatives such as thick-film or thin-film resistors. Their capacity to handle larger loads and sustain higher temperatures makes them suitable for demanding applications. While thick-film resistors are compact and efficient in low-power situations, wirewound resistors shine in high-power environments where thermal management is critical. Moreover, they can be customized for varying resistance values, which is less feasible with some other types. However, they may take up more space compared to compact film types, making the choice largely dependent on the specific requirements of the energy storage system.

CAN RESISTORS IMPACT ENERGY STORAGE EFFICIENCY?

Yes, the choice of resistors can significantly influence the efficiency of energy storage systems. Poor resistor selection may lead to excess heat generation and energy loss, ultimately causing decreased performance of the entire system. For example, if a power resistor does not dissipate heat efficiently, it can lower overall energy retention capacity and lead to equipment failures over time. Conversely, employing high-quality, appropriately rated resistors enhances thermal management and helps maintain optimal operating conditions. Ultimately, effective resistor implementation contributes to maximizing energy storage efficiency, ensuring reliable performance in modern applications.

The discussion surrounding resistors in energy storage stations reveals a multi-faceted understanding of how these components contribute to the overall efficiency and performance of energy management systems. From power resistors to high-frequency options, each type offers distinct advantages tailored to specific applications and operational needs. Understanding the unique properties and applications of these resistors enables engineers and designers to make informed decisions that enhance the functionality of energy storage systems, ultimately leading to more reliable and efficient energy management solutions. As technology progresses, the demand for high-quality resistors continues to rise, pushing the boundaries of energy efficiency in storage stations. Capacities are likely to expand as industry standards evolve, highlighting the importance of advanced resistor technologies in meeting both current and future energy demands.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-resistors-are-used-in-energy-storage-stations/