1. The following types of pipe fittings are commonly utilized for solar solenoid valves: 1. PVC fittings, 2. Brass fittings, 3. Stainless steel fittings, 4. Compression fittings. Notably, PVC fittings are often favored in solar thermal systems due to their resistance to corrosion and ease of installation. They can withstand higher temperatures associated with solar applications, ensuring durability and efficiency in fluid control.

UNDERSTANDING SOLAR SOLENOID VALVES

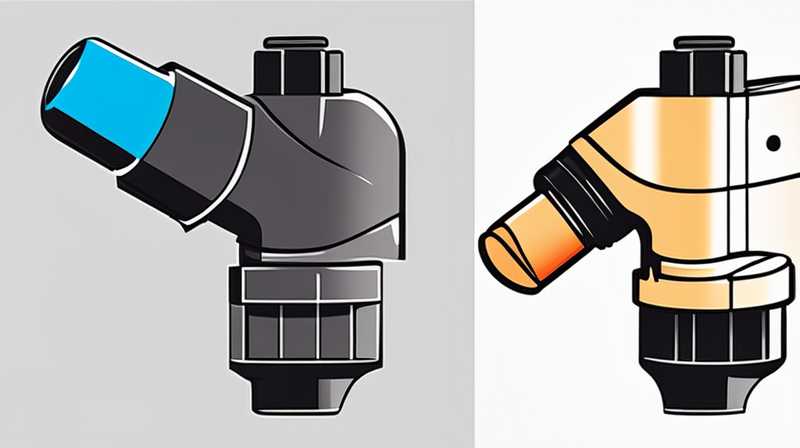

Solar solenoid valves serve a pivotal role in managing fluid flow within solar energy systems. These valves act as automated components, enabling the control of water or other heat transfer fluids that circulate through solar collectors and storage tanks. The essence of their function lies in their ability to respond to electrical signals, subsequently opening or closing based on the conditions present in the system. This automatic regulation is essential for optimizing energy collection and delivery while preventing boiler or collector overheating.

The valve mechanism within these systems relies on a solenoid coil, which, when energized, generates a magnetic field. This field subsequently pulls a plunger, allowing liquid to flow through the valve. Conversely, when the electrical current ceases, the plunger returns to its resting position, halting flow. Understanding the intricate functions of solar solenoid valves underlines the importance of the correct fitting selection, which ensures that the system operates reliably at all times.

TYPES OF PIPE FITTINGS FOR SOLAR SOLENOID VALVES

1. PVC FITTINGS

PVC (Polyvinyl Chloride) is one of the most commonly used materials in the assembly of solar systems when piping is needed. PVC fittings are lightweight and offer significant resistance to corrosion, making them particularly suitable for environments where exposure to water and chemicals is inevitable. This characteristic is especially important in solar thermal systems, where varying temperatures can lead to potential equipment degradation.

The ease of installation is another compelling reason for choosing PVC fittings for solar solenoid valves. They can be glued together using solvent cement, resulting in a leak-proof and robust connection. Furthermore, their affordability makes them an attractive option for both DIY and professional installations. However, it is crucial to note that while PVC fittings are versatile, they may not endure extremely high-temperature scenarios. Thus, selecting the correct type rated for higher temperatures ensures longevity in solar applications.

2. BRASS FITTINGS

Brass fittings are another viable option for connecting solar solenoid valves. These fittings are constructed from an alloy of copper and zinc, renowned for exceptional durability and corrosion resistance. In environments where high-temperature water flows, brass fittings provide a reliable option, as they can withstand significant thermal expansion and contraction without compromising integrity.

Additionally, brass fittings boast excellent mechanical properties, allowing them to handle higher pressure levels compared to alternative materials. Their inherent strength makes them ideal choices in systems that require high fluid flow rates. While typically more expensive than PVC options, the longevity and resilience of brass can ultimately justify the investment, particularly in high-performance solar systems.

3. STAINLESS STEEL FITTINGS

For systems that prioritize longevity and strength, stainless steel fittings are excellent. Known for their superior resistance to rust and corrosion, stainless steel components perform reliably over extended periods, even in harsh environmental conditions. This resilience is vital for solar applications, where systems may be exposed to sunlight, rain, and other environmental stressors.

Stainless steel also exhibits impressive strength under pressure, making it suitable for systems requiring high flow rates and temperature regulation. Installation of stainless steel fittings often involves welding or the use of specialized sealants, which can require additional labor and expertise. However, the investment in stainless steel fittings is often recouped through reduced maintenance costs and enhanced system performance.

4. COMPRESSION FITTINGS

Compression fittings are distinguished by their unique design, utilizing a compression ring to create a tight seal around the pipes being connected. These fittings are particularly advantageous for various piping systems, including those used in solar solenoids. They are self-sealing and do not require additional sealants, simplifying installation and maintenance.

An additional benefit of compression fittings is their adaptability. They can accommodate slight variations in pipe diameters while still ensuring secure connections. This feature is especially helpful for troubleshooting or modifying existing solar systems. While compression fittings can be somewhat pricier than other options, their reliability and ease of use in maintenance scenarios make them a favorable choice.

5. SELECTING THE RIGHT PIPE FITTINGS

The decision-making process regarding the selection of pipe fittings is complex and should factor in various fundamental elements. Regarding solar solenoid valves, significant considerations include application type, temperature range, pressure class, and fluid characteristics. Each of these elements plays a role in how the overall solar system will perform and operate in the long term.

Additionally, when choosing pipe fittings, consider how the particular characteristics of the fitting material complement the operational requirements of the solar system. For instance, while PVC may be exceptionally cost-effective, its application should be limited to areas where extreme heat isn’t a concern. Alternatively, investing in stainless steel for high-temperature applications can prevent costly damage and ensure prolonged effectiveness.

6. INSTALLATION BEST PRACTICES

Proper installation of pipe fittings in conjunction with solar solenoid valves is crucial to ensuring system integrity. Pre-installation assessment should include checking all components for compatibility, dimensions, and overall quality. Following manufacturer specifications during the installation process will significantly minimize the risk of malfunction later.

It is also critical to implement accurate torque specifications when securing fittings to prevent damage from overtightening. Maintaining the appropriate level of tightness helps promote optimal sealing, eliminating potential issues with leakage. Continuous inspections and maintenance of fittings in installed systems ensure that any anomalies can be addressed promptly, preserving the overall efficiency of the solar application.

COMMON INQUIRIES

WHAT ARE THE ADVANTAGES OF USING PVC FITTINGS FOR SOLAR SOLENOID VALVES?

PVC fittings are widely recognized for their affordability and lightweight nature. Their inherent resistance to corrosion ensures long-term performance in fluid systems, particularly in scenarios exposed to moisture and chemicals. Furthermore, the ease of installation through solvent bonding simplifies the overall assembly, allowing quicker deployment of solar systems. However, it is critical to select PVC materials rated for higher temperature applications to prevent any risk of melting or degradation in intense environments.

Additionally, these fittings are versatile and can be used in various applications beyond solar energy, which enhances their value. Despite their limitations in handling extreme pressures, PVC remains a popular choice for many solar installations simply due to its unique advantages. Ensuring proper installation practices can significantly extend the lifespan and effectiveness of the material, making it an attractive choice for managing fluid in solar systems.

HOW DO I MAINTAIN PIPE FITTINGS IN SOLAR SYSTEMS?

Guidelines for maintaining pipe fittings primarily revolve around periodic inspections and regular servicing. Closely monitoring the fittings for signs of wear, leakage, or corrosion is essential to identifying problems before they escalate. In addition, visual examinations can help recognize any stress or cracks that may compromise the fitting’s functionality.

Regular cleaning of the connections reduces the risk of buildup that can lead to blockage or pressure loss within the system. For metallic fittings such as brass and stainless steel, applying protective coatings can reduce corrosion risks. Finally, following manufacturer recommendations for service intervals and replacement schedules contributes significantly to ensuring the long-term reliability and efficiency of solar installations.

WHAT FACTORS SHOULD I CONSIDER WHEN CHOOSING PIPE FITTINGS?

Several factors come into play when determining the most suitable pipe fittings for solar solenoid valves. Assessing the fluid type being managed is of utmost importance, as compatibility with chemicals or temperatures is critical for performance. The pressure rating of the fitting should align with the system’s operational parameters to prevent any integrity issues.

Additionally, environmental considerations should not be overlooked. For instance, locations subjected to extreme weather conditions may necessitate more robust fittings to prevent deterioration over time. The ease of installation and maintenance should also be scrutinized, as complex fittings may require more expertise and time to apply and service effectively. By carefully evaluating these aspects, one can make informed decisions regarding pipe fittings.

Through thoughtful considerations and analysis, selecting pipe fittings for solar solenoid valves emerges as a critical aspect of constructing and maintaining functional solar systems. The choice between PVC, brass, stainless steel, and compression fittings underscores the importance of aligning materials with operational requirements. Each type presents unique strengths that cater to specific situations, further emphasizing the need for extensive understanding prior to making selections. Ensuring that fittings are correctly installed and maintained is just as pivotal as selecting the right materials. Regular inspections and proactive maintenance not only safeguard against failures but significantly enhance the effectiveness of the overall solar installation. As the demand for renewable energy solutions continues to rise, mastering the intricacies of pipe fitting selections and applications will play a vital role in the success of solar energy systems. Ultimately, the enhancement of performance, reliability, and longevity hinges on the informed choices made during planning and execution phases of these projects.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-pipe-fittings-are-used-for-solar-solenoid-valves/