1. Energy storage inductors are primarily manufactured using materials such as ferromagnetic substances, ferrites, and non-magnetic conductive materials. 2. These elements play a pivotal role in defining the efficiency and performance of inductors. 3. Ferromagnetic materials, for example, enhance magnetic field strength and energy retention, while ferrites reduce energy loss. 4. Other materials, like aluminum and copper, are essential for the windings that facilitate energy transfer.

MATERIALS IN ENERGY STORAGE INDUCTORS

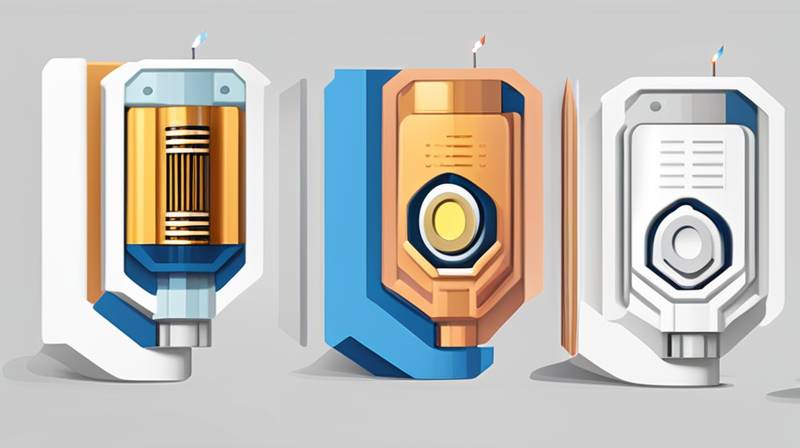

Inductors are pivotal components in electrical circuits, serving the primary function of storing energy in the form of a magnetic field. Materials used in the construction of these components significantly impact their performance, efficiency, and application. Understanding these materials encompasses examining their properties, costs, and implications for energy storage capabilities.

1. FERROMAGNETIC MATERIALS

Ferromagnetic materials, which include elements such as Iron, Nickel, and Cobalt, have notably high magnetic permeability, allowing them to store substantial magnetic energy. These materials are revered for their ability to exhibit magnetization; they can be easily magnetized and demagnetized without losing magnetism efficiently.

Inductors made from ferromagnetic substances can effectively increase the magnetic field generated around them when current flows. This property amplifies energy storage, making inductors created from these substances suitable for applications requiring high energy retention, such as in transformer cores and high-frequency applications. However, one must also consider the drawbacks, such as core saturation and losses due to hysteresis, which can arise at high operation frequencies, thereby limiting their effectiveness.

2. FERRITES

Ferrites, specialized ceramic compounds of iron oxide combined with other metallic oxides, represent another significant category of materials for inductors. These composites exhibit high electrical resistance and substantial magnetic permeability, rendering them suitable for high-frequency applications. Ferrites effectively minimize energy loss, thereby enhancing performance.

One of the compelling features of ferrites is their frequency response, which allows inductors to operate efficiently across various frequencies. Additionally, ferrites can be molded into specific geometries, enabling design flexibility in inductor construction. Their low eddy current losses make them ideal for high-frequency transformers and inductors, where efficiency is paramount. The precise formulation of ferrite materials, tailored for specific applications, demonstrates the advancements in material science relating to inductors.

3. NON-MAGNETIC CONDUCTIVE MATERIALS

While the core material of inductors plays a vital role, the conductive wire used in windings remains equally critical. Typically made from metals like copper or aluminum, these materials facilitate current flow while inducing magnetic fields around the coil. Copper, with its high conductivity and low resistive losses, is primarily preferred, but aluminum is also popular due to its lightweight characteristics and cost-effectiveness.

The choice of conductive material affects both the performance and the overall efficiency of the inductor. The resistance of the wire influences how much energy is lost as heat during operation, which can impact the inductor’s effectiveness in energy storage applications. Therefore, understanding the interplay between core materials and conductive elements is essential in producing efficient inductors that meet specific application needs.

4. COMPOSITE MATERIALS

The exploration into composite materials, which combine different substances to enhance the properties of inductors, is gaining traction in modern design. Using hybrid materials allows for the blending of the advantageous characteristics of each component into a composite product. For example, combining ferrimagnetic materials with conductive polymers can lead to inductors that exhibit both high resilience to high-frequency losses and adjustment flexibility.

The crafting of composite materials involves intricate processes that demand expertise in material science and engineering, creating a favorable path for advancements in energy storage technology. Moreover, these composite inductors can achieve significant reductions in size and weight while maintaining or even improving performance metrics. This innovation signifies a leap forward, addressing the growing demand for more compact energy storage solutions in modern electronic devices.

COMMON INQUIRIES

WHAT IS THE ROLE OF MATERIAL SELECTION IN INDUCTOR PERFORMANCE?

The selection of materials in inductor construction critically influences efficiency, energy storage capabilities, and reliability. High-permeability ferromagnetic materials enhance the magnetic field, which is crucial for energy storage. Non-magnetic conductive materials used in windings determine how well the inductor transmits energy with minimal losses. The careful selection is imperative to ensure the inductor functions optimally under specific operating conditions, addressing various technological requirements.

HOW DO FERRITES COMPARE TO FERROMAGNETIC MATERIALS?

Ferrites and ferromagnetic materials serve distinct yet overlapping purposes in inductors. Ferrites operate well at higher frequencies due to lower eddy current losses, while traditional ferromagnetic materials excel at low frequencies with higher energy storage densities. The choice depends on the operational frequency and specific application requirements. Ferrites are generally preferred in applications requiring high-frequency operations, while ferromagnetic materials might be chosen for power-related components where robust energy storage is essential.

WHAT IMPACT DO WINDING MATERIALS HAVE ON INDUCTOR EFFICIENCY?

Winding materials significantly influence resistive losses and, subsequently, the overall efficiency of inductors. Higher conductivity materials like copper minimize resistive losses, facilitating better energy transfer. In contrast, using materials with lower conductivity can result in higher energy losses, adversely affecting performance. Therefore, selecting appropriate conductive materials for windings is crucial for optimizing inductor performance, particularly where efficiency is a key concern.

Energy storage inductors rely on various materials that play essential roles in performance characteristics, with each material contributing distinct advantages and drawbacks. The blend of ferromagnetic substances, ferrites, conductors, and composites signifies the complexity of engineering effective inductors. The choice of materials not only dictates the energy retention capabilities but also the operational frequency limits, size, and weight characteristics of inductors in practical applications. Advances in material science continue to push the boundaries of inductor design, allowing for innovative solutions to modern technological challenges. Furthermore, ongoing research into composite materials and novel combinations promises to create more efficient, compact inductors capable of meeting the demands of various industries. The future of energy storage inductors appears vibrant, with constant evolution in methodology and materials, addressing both performance and efficiency in electrical and electronic applications.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-material-is-used-for-energy-storage-inductor/