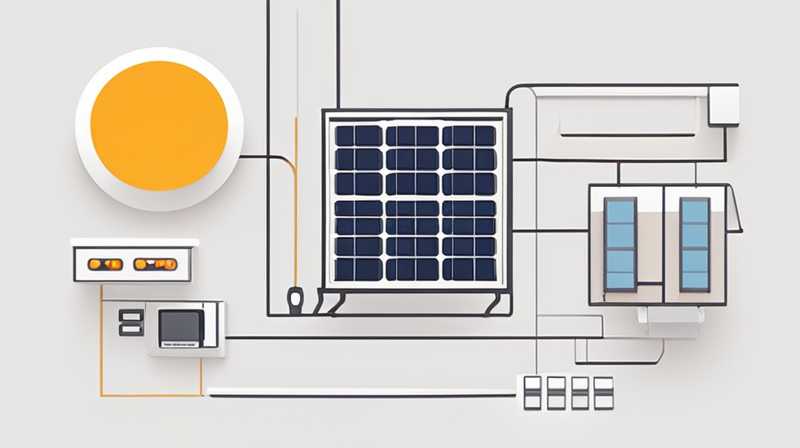

To determine what kind of wire is optimal for solar panel leads, several factors must be considered, leading to key conclusions. 1. Copper is preferred for its superior conductivity, making it an excellent choice for solar installations. 2. The wire gauge should be appropriate for the current being transmitted to minimize voltage drop. 3. Insulation rating is crucial to ensure that the wire can withstand environmental conditions without degrading. 4. Using UV-resistant and weatherproof insulation is essential for outdoor applications. Let’s delve deeper into each of these components for a comprehensive understanding.

1. MATERIAL SELECTION

Selecting the right material for solar panel leads is of utmost importance. Copper wire is the most popular choice due to its remarkable electrical conductivity, making it better than aluminum. Conductivity implies that copper can transmit electricity more efficiently, leading to reduced energy losses.

In addition, another aspect to note is the longevity and reliability of copper. Copper wires are less prone to corrosion, which is critical for their performance over time. They provide a robust solution that maintains efficiency even under varying weather conditions. However, copper is often more expensive than aluminum, which might influence decision-making in budget-conscious projects.

Nonetheless, the investment in copper yields higher returns in terms of efficiency and reliability during the life cycle of solar energy systems. Copper’s excellent thermal performance also adds value, particularly in solar applications where heat can impact efficiency.

2. WIRE GAUGE

The appropriate wire gauge is essential for any solar installation, as it affects not only the current-carrying capacity but also the voltage drop across the wire length. A wire that is too thin may cause heat buildup, which can lead to inefficiencies and potential hazards. Conversely, a thicker wire may lead to unnecessary expenditure without significant benefits.

For solar systems, the American Wire Gauge (AWG) system is utilized to measure wire thickness. Commonly used gauges for solar panel leads range from 10 AWG to 14 AWG. As a rule of thumb, thicker wires (lower AWG numbers) should be chosen for longer runs or higher voltages. This choice reduces resistive losses, consequently improving the overall performance of the solar system.

When determining the gauge, it’s also vital to consider the length of the wire run and the power output of the solar panels. Tables and calculators are often available to help installers determine the optimal gauge based on these specifications. Thus, understanding these nuances is essential for ensuring maximum efficiency and safety.

3. INSULATION RATING

The insulation surrounding the wire is crucial for protecting it from external damage and ensuring longevity in various conditions. The insulation rating must meet specific standards, which indicate its ability to resist thermal and mechanical degradation.

For solar panel leads, wires often have insulation rated for at least 90 degrees Celsius. Additionally, look for wires insulated with materials that are UV-resistant. Given that solar installations primarily reside outdoors, exposure to sunlight can degrade certain materials over time, leading to a decline in performance.

Furthermore, the insulation must be resistant to moisture and other environmental factors such as saltwater or pollutants. This is essential for installations in coastal areas or regions with high humidity. Improper insulation can lead to short circuits or system failures, hence investing in high-quality, durable insulation is critical.

4. ENVIRONMENTAL CONSIDERATIONS

When selecting wires for solar panel leads, environmental compatibility should not be overlooked. The manufacturing process and materials used in wire production can impart ecological impacts. For environmentally conscious consumers, many companies now offer eco-friendly wire options.

Solar lead wires that are manufactured with sustainable practices and recycled materials are gaining traction. These options not only reduce the ecological footprint but can also enhance the appeal of solar installations among environmentally aware customers.

Moreover, some wires are treated to resist harmful conditions such as corrosion from saline environments or degradation from UV light. Ensuring that wires are both effective and environmentally sound enhances the sustainability of entire solar systems. By prioritizing sustainable materials and processes, installers promote a more responsible approach to renewable energy.

5. IMPLEMENTATION STRATEGIES

Upon determining the type of wire suitable for solar panel leads, the next step lies in implementation. Proper installation techniques are vital for the effective performance of solar systems. Using high-quality connectors and avoiding sharp bends during installation will prevent stress on the wire, which could potentially lead to failure.

Another essential strategy is the meticulous checking of connections. Loose connections can result in overheating and energy loss, hindering system efficiency. When dealing with solar installations, ensuring that all wiring adheres to national and local electrical codes is imperative to guarantee system safety and effectiveness.

Additionally, regular maintenance checks can help ensure that connections remain intact and that wiring insulation hasn’t degraded over time. Periodic inspections can catch potential issues early, allowing for prompt repairs that can mitigate costly replacements down the line.

6. COST ANALYSIS

Understanding the cost implications of your wire choice is essential when planning a solar project. Generally, higher-quality materials such as copper will come at a premium; however, the long-term benefits can offset this initial investment.

When evaluating costs, it’s crucial to consider not only the initial price of the wire but also its expected lifespan, efficiency, and the potential costs associated with replacements or repairs. Choosing a high-quality wire could lead to significant savings in energy efficiency over time, translating to lower utility bills and a quicker return on investment.

Furthermore, many installers may see variance in prices based on market conditions and supplier availability. Using multiple suppliers and comparing quotes may offer cost-effective solutions without compromising quality. These cost analyses ensure you’re making the most informed decision possible, ultimately benefiting the broader solar installation project.

FREQUENTLY ASKED QUESTIONS

WHAT TYPE OF WIRE SHOULD BE USED FOR SOLAR INSTALLATIONS?

For solar installations, copper wire is highly recommended due to its outstanding conductivity and resilience. The choice of wire gauge is also critical; commonly used gauges include 10 AWG to 14 AWG, depending on the installation size and distance limitations. Moreover, insulation ratings should not be neglected, as higher ratings ensure the wire can endure extreme weather conditions and UV exposure. Opting for wires with superior insulation materials will ultimately yield the best long-term performance for solar systems.

HOW DOES WIRE GAUGE IMPACT SOLAR SYSTEM PERFORMANCE?

Wire gauge significantly impacts a solar system’s overall performance by influencing the current-carrying capability and voltage drop along the wire length. A wire that is too thin could lead to increased resistance, generating heat and energy loss. Therefore, selecting an appropriate gauge is fundamental for maintaining efficient energy transfer, especially over longer distances. Professionals usually rely on the American Wire Gauge (AWG) system to determine the best gauge suited for the voltage and distance involved in a specific solar installation.

WHY IS INSULATION IMPORTANT FOR SOLAR PANEL LEADS?

The insulation protecting solar panel leads is vital for several reasons. First, it guards against environmental factors that could lead to deterioration, such as UV rays, moisture, and extreme temperatures. Secondly, proper insulation prevents electrical shorts that could jeopardize both system functionality and safety. Insulation that meets or exceeds industry standards ensures durability and longevity, making investment in high-quality insulated wires critical for successful and safe solar installations.

FINAL REMARKS

Selecting the right wire for solar panel leads encompasses numerous considerations, from material type to insulation quality, all of which contribute to the installation’s overall efficiency. Copper, due to its unrivaled conductivity and resistance to corrosion, emerges as the superior option for conducting electricity from solar panels to inverters and storage solutions. Therefore, investing in quality copper wire is a fundamental decision in the planning phase of solar installations. This is complemented further by choosing the correct wire gauge, ensuring that it is neither too thin nor excessively thick for optimal current transmission.

Moreover, insulation selection plays a pivotal role in safeguarding the wires against environmental adverse effects, enhancing the system’s longevity. Environmental considerations is another crucial factor; eco-friendly wire options not only promote sustainability but can also play a role in the marketability of solar installations. Each of these choices contributes significantly to the efficacy of solar energy systems, as does proper implementation and maintenance. Understanding the costs associated with various wiring options helps ensure a project remains feasible and valuable in the long run, ultimately furthering the domain of renewable energy solutions.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-kind-of-wire-is-good-for-solar-panel-leads-2/