1. For solar panel leads, the most suitable wire consists of stranded copper, specifically with a gauge of 10-12, and UL certification. These wires exhibit excellent conductivity, flexibility, and durability, which are essential for optimal solar energy transfer and longevity. 2. Using a stranded rather than solid wire is crucial, as it allows for greater flexibility and makes installation easier in various settings. 3. The wire should also be insulated with weather-resistant materials, ensuring long-lasting performance in harsh environments. 4. Finally, utilizing wires that meet industry standards enhances safety and minimizes risks related to electrical failures.

1. UNDERSTANDING THE NEED FOR APPROPRIATE WIRING IN SOLAR SYSTEMS

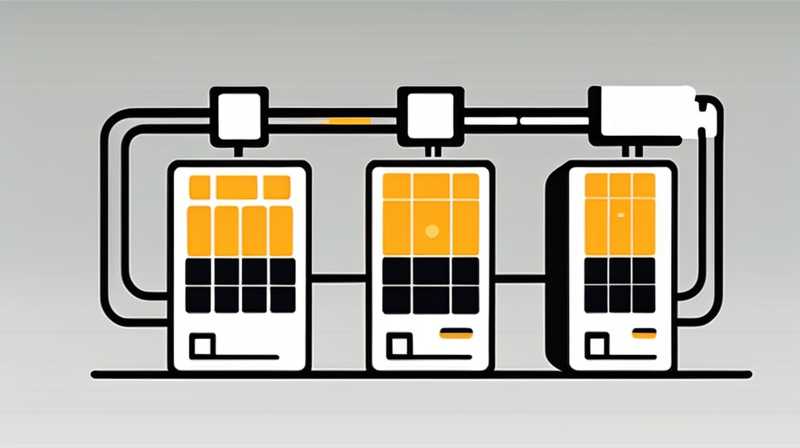

In the realm of solar energy systems, selecting the right wiring for the connections is pivotal. Wiring connects solar panels to the inverter and ultimately to the electrical system of a building. Thus, the choice of wire directly affects the efficiency and safety of the entire solar setup. Various factors come into play when determining the most suitable wire, including corrosion resistance, heat resistance, and proper gauge size.

Many installers tend to overlook the significance of wire quality, focusing instead on panel and inverter types. However, as technology has advanced, so too have the materials used in wiring. Understanding the specific requirements of solar energy systems ensures not only optimal energy transfer but also the longevity and durability of the installations.

2. MATERIALS USED IN SOLAR PANEL WIRING

When it comes to wiring for solar panel leads, materials play a crucial role in performance. Copper is the most widely used material, primarily because of its superior conductivity compared to other metals. As a conductor, it facilitates the efficient transfer of electricity from the solar panels to the inverter, mitigating potential loss in energy. Especially for solar applications, using high-purity copper enhances the overall effectiveness of the system.

In contrast, aluminum can be an alternative, often marketed as a cost-effective solution. While it is lighter and generally cheaper than copper, its conductivity is significantly lower. This decreased efficiency means that more aluminum is needed to achieve the same level of conductivity, which can result in heavier wires that are more challenging to install.

3. WIRE GAUGE SELECTION

Wire gauge selection is critical in determining how much current a wire can safely carry. In solar applications, wire sizes typically range from 10 AWG to 12 AWG for leads. The American Wire Gauge (AWG) system is a standardized wire gauge system that indicates the diameter of the wire. A lower gauge number signifies a thicker wire, which can handle higher currents without overheating or becoming a fire hazard.

The thickness of the wire impacts resistance and performance. Wider wires have less resistance and can carry more current without significant voltage drops. This characteristic is crucial for systems utilizing multiple panels, as it ensures efficient energy transfer and diminishes losses, allowing the system to operate at peak efficiency.

4. INSULATION AND PROTECTION

The insulation surrounding the wire is equally essential as the wire itself. For solar panel leads, the insulation must withstand various environmental factors, including ultraviolet light, moisture, and extreme temperatures. Polyvinyl chloride (PVC) and cross-linked polyethylene (XLPE) are common materials used for insulation because of their durability and weather-resistant properties.

Choosing appropriately rated wire for outdoor use is imperative. Many wires come with specific certifications indicating their resistance to heat, cold, and ultraviolet rays. These ratings ensure that the wire can withstand outdoor usage throughout the year, thus enhancing the lifespan and resilience of the entire solar panel installation.

5. FLEXIBILITY AND INSTALLATION CONSIDERATIONS

Another significant feature of wiring is flexibility. Stranded wires, as opposed to solid conductors, offer better flexibility, making them easier to install in tight spaces or intricate designs. This flexibility is especially advantageous when routing wires through wiring channels or connectors that demand intricate installation techniques.

Adequate installation techniques also play a role in longevity. Proper bending radii and securing methods ensure that the wires are not subjected to undue stress, which can cause fatigue over time. By using stranded wires, installers can create more adaptable layouts without sacrificing efficiency or safety.

6. SAFETY REGULATIONS AND STANDARDS

Safety regulations govern how electrical systems are installed in both residential and commercial environments. Wiring for solar panel leads must comply with local codes and regulations, which often specify the precise materials and gauges to be utilized. Compliance with these standards is crucial for ensuring safe operation and protecting individual investments.

UL certification is a prominent example of an internationally recognized safety standard. Wires and cables with this certification undergo rigorous testing for fire resistance and electrical performance, making them a reliable choice for solar applications. Selecting wires that meet or exceed these safety standards reduces risks associated with electrical fires or failures.

7. COST CONSIDERATIONS

While the initial cost of wiring may seem minimal compared to other components of a solar installation, choosing high-quality wiring can lead to significant savings in the long run. Investing in superior wire materials, such as high-purity copper and weather-resistant insulation, may incur higher upfront costs. However, the enhanced efficiency and durability translate to lower maintenance and replacement costs over the years.

Moreover, systems designed with the right wiring can operate more efficiently, boosting energy production. This enhancement can contribute to faster payback periods for solar investments, ultimately benefiting homeowners or businesses financially while promoting the use of renewable energy.

8. IMPACT ON SYSTEM EFFICIENCY

The efficiency of a solar energy system heavily relies on the quality of the wiring used. Every component, from the solar panels to the inverter and the battery storage, can contribute to energy losses if not correctly matched with the right wiring. Voltage drops can occur when the wrong gauge of wire is used, resulting in pinpoint inefficiencies that can thwart the system’s viability.

Additionally, as systems scale up in size, even minor energy losses can result in substantial losses overall. This challenge underscores the importance of properly specifying wire types and gauges to maximize energy collection and transfer efficacy. Charged with extensive research, one can find that the right wire determinants are essential for achieving optimal energy production.

9. LONG-TERM PERFORMANCE AND DURABILITY

Selecting high-quality wire isn’t just about immediate efficiency; it’s also a commitment to long-term performance and durability. Wires installed in solar systems should be envisioned as integral aspects of renewable energy sustainability. Over time, inferior materials may fail more quickly, resulting in increased costs and inefficiencies, while robust wires promise to last throughout the lifespan of the solar setup.

Heat resistance, resistance to UV light, and moisture resilience are vital in ensuring that the wiring remains intact and functional over the years. This prolonged durability can help avoid disruption in energy production and lessen the maintenance and repair burden on system owners.

10. REVOLUTIONIZING SOLAR TECHNOLOGY: FUTURE TRENDS IN WIRING

The world of solar technology continues to evolve, bringing forth innovative wiring solutions that promise enhanced performance and adaptability. Conductors of the future may utilize advanced materials that offer better conductivity and resistance to environmental factors. These advancements could yield wires that are even lighter, more flexible, and capable of withstanding harsher conditions.

Emerging technologies may lead to wires that incorporate smart features, allowing for better monitoring of energy flow and efficiency. Such innovations will not only help improve performance in real-time but also provide valuable data for system optimization. Consequently, the ongoing research and development in wiring technology highlight an exciting path forward for solar energy systems.

FAQs

WHAT IS THE IDEAL WIRE GAUGE FOR SOLAR PANEL LEADS?

The most recommended wire gauge for solar panel leads varies between 10 AWG and 12 AWG. The choice between these two sizes generally hinges on the amount of current the solar panels will produce, the distance between the panels and the inverter, and overall system design. Thicker wires, like 10 AWG, possess lower resistance, effectively minimizing voltage loss, particularly for larger systems spanning extensive distances. Ensuring compliance with local electrical codes is essential, as specific regulations might dictate which gauge is acceptable based on installation circumstances.

Cost considerations also come into play when choosing the wire gauge, as thicker wires could lead to higher material costs. However, in the long run, investing in adequately sized wiring contributes to system efficiency and longevity, as well as safer operation. Hence, the ideal wire gauge optimally balances safety, efficiency, and cost.

WHY IS COPPER PREFERRED OVER ALUMINUM FOR SOLAR WIRING?

Copper is often the preferred choice for solar panel wiring compared to aluminum due to several compelling attributes. First and foremost, copper boasts superior electrical conductivity, markedly outperforming aluminum. This enhanced conductivity translates to lower resistance, which ultimately diminishes energy losses during the transmission of electricity from solar panels to the inverter and other connections. The reduced voltage drop ensures that more of the generated power reaches end users efficiently.

Aluminum, while generally lighter and less expensive, has its downsides. Its conductivity is significantly lower, meaning that more aluminum must be used to achieve equivalent performance, leading to potential weight and installation complications. Furthermore, copper’s resistance to corrosion and longer lifespan make it a more reliable investment in the long term, which is particularly important in outdoor environments where wiring may be exposed to various elements.

WHAT ROLE DOES INSULATION PLAY IN SOLAR PANEL WIRING?

The insulation surrounding solar panel wiring performs several vital functions, with prominent features being protection and durability under various environmental conditions. Effective insulation adds a layer of safety by preventing accidental contact between wires and other conductive elements, which could lead to short circuits or electrical faults. Moreover, high-quality insulation materials must resist ultraviolet (UV) radiation, moisture, and thermal variations to maintain their performance over time.

Additionally, insulation helps preserve the integrity of the wires within. Poor-quality insulation can deteriorate over time, exposing the wires to potential damage and compromising the entire solar array’s functionality. As electricity flows through the wires, insufficient insulation may also lead to heat buildup, further increasing safety hazards. Thus, selecting well-insulated wiring is crucial in ensuring a safe and reliable solar power system.

In summary, the specifics of selecting wires for solar panel leads involve understanding materials, gauge selections, insulation, and safety regulations. The chosen wire has a directly proportionate effect on overall efficiency, flexibility, installation ease, long-term performance, and compliance with safety standards. As advancements in solar technology continue, the focus on proper wiring options will undoubtedly play a key role in enhancing the energy generation and sustainability of solar systems. Making informed choices today lays the groundwork for energy-efficient solutions that will benefit not just individual users but society as a whole, paving the way for a greener planet.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-kind-of-wire-is-good-for-solar-panel-leads/