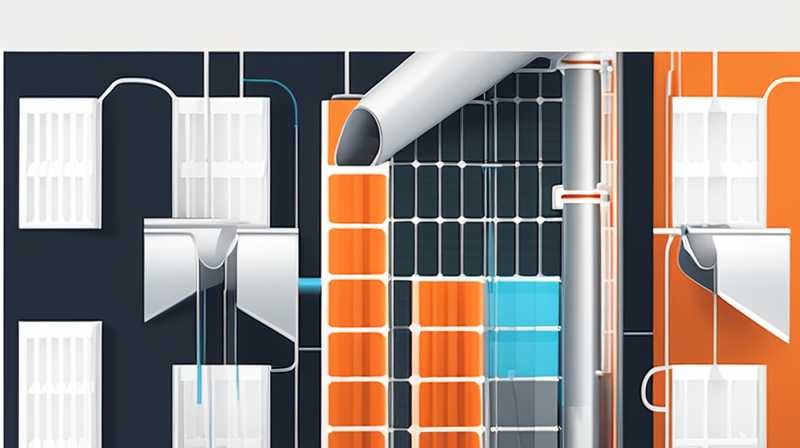

In solar installations, various pipes are utilized, ensuring effective operation and longevity of the system. 1. The most commonly used materials include copper and PEX, 2. Insulation is crucial for maintaining efficiency, 3. Pressure ratings play a significant role in system design, 4. The choice depends on the specific needs of the installation. The discussion around pipe choices for solar applications primarily centers around copper pipes due to their superior heat conduction properties and durability, making them a preferred option in many setups. Conversely, PEX, a type of flexible plastic pipe, has gained traction for its ease of installation and resistance to environmental damage, despite its limitations in high-temperature applications.

1. MATERIALS USED IN SOLAR INSTALLATIONS

The utilization of different materials in the construction of pipes for solar installations is pivotal in determining system efficacy and durability. Copper has long been heralded as a leading material for solar thermal applications, and it boasts several advantages. Its ability to conduct heat efficiently ensures that minimal energy loss occurs during the transfer of heat from the solar collectors to the storage tanks. Copper pipes are resistant to corrosion and can withstand high temperatures, making them suitable for various climates and operating conditions. Their longevity in the system can justify the higher upfront costs compared to other materials.

In contrast, PEX (cross-linked polyethylene) pipes offer unique benefits that have made them increasingly popular in newer installations. One of the major advantages of PEX is its flexibility, which simplifies installation in complex layouts. Unlike rigid pipes, PEX can bend around corners and obstacles without the need for additional fittings, significantly reducing labor costs and installation time. Furthermore, PEX is resistant to scale buildup and chlorine, which enhances the longevity of the plumbing system. However, its temperature limitations make it less suitable for high-temperature applications like solar heating when used for domestic hot water.

2. INSULATION REQUIREMENTS

Insulation in solar piping systems is of paramount importance. Effective insulation prevents heat loss, which can significantly reduce the overall efficiency of the solar system. Heat transfer can occur through the pipes, and without adequate insulation, even a well-functioning solar system can fail to deliver the anticipated energy savings. Insulating the pipes maintains the temperature of the fluid being transported, ensuring that solar energy is conveyed effectively to storage systems or directly used for heating.

There are various materials used for insulation, including polyurethane foam, fiberglass, and reflective foil. Foam insulation is particularly effective due to its low thermal conductivity properties. It can be wrapped around the pipes to minimize heat loss. In addition to preventing energy loss, proper insulation also protects the pipes from external elements, such as freezing temperatures during winter, which could lead to pipe burst and system failure. As a result, investing in appropriate insulation materials and installation techniques is crucial to maximize the effectiveness and reliability of solar installations.

3. PRESSURE RATINGS AND STANDARDS

Understanding the pressure ratings associated with pipes used in solar installations is essential for ensuring system integrity and safety. Pipes need to withstand the internal pressures generated from the heating process and the fluid dynamics involved. Systems must be designed to accommodate fluctuations in pressure, which can arise from thermal expansion, particularly in high-temperature solar thermal systems. Each type of pipe has a specific pressure rating which indicates the maximum pressure it can handle safely, commonly denoted in pounds per square inch (PSI).

In general, copper pipes have considerably high pressure ratings, making them ideal for residential and commercial solar thermostat applications. PEX pipes, on the other hand, have lower pressure ratings compared to copper but are still sufficient for many installations, particularly where high pressures are not a concern. However, attention must be paid to the characteristics of the solar system’s design, including potential thermal expansion, pressure fluctuations, and temperature, as these factors influence the reliability and lifespan of the piping system significantly.

4. FACTORS INFLUENCING PIPE CHOICE

Selecting the appropriate pipe material for solar installations is influenced by multiple factors. The specific type of solar system being installed plays a crucial role. For instance, active solar heating systems that utilize pumps and circulators often benefit from the durability and efficiency of copper pipes, while passive systems could effectively employ PEX due to its lightweight and cost-effectiveness.

Additional considerations include budget implications, local climate conditions, and system size. Cost concerns often drive the choice between materials, especially for large installations where the price difference can become significant. Installation practices and expertise also factor into the decision. Some regions may have a greater availability of PEX, while in others, copper is readily available and preferred for its proven track record. Ultimately, the choice of piping must reflect both performance expectations and economic feasibility, aligning with the project’s overall design objectives.

FREQUENTLY ASKED QUESTIONS

WHAT IS THE IDEAL PIPE FOR SOLAR INSTALLATIONS?

Selecting the ideal pipe for solar installations hinges on multiple aspects, including system type, budget constraints, and environmental conditions. Copper pipes are often favored for high-temperature applications due to their excellent heat conduction capabilities and durability; they ensure minimal energy loss in transferring heat from collectors to storage systems. However, they can be more expensive and complex to install. Conversely, PEX pipes present a cost-effective, flexible alternative that simplifies layout adaptations, especially in retrofits or complex designs; they are particularly well-regarded for their resistance to scale and chlorine but have limitations regarding maximum temperature thresholds. An ideal choice often blends these materials, utilizing copper for heat transfer while employing PEX in less critical roles. Ultimately, careful assessment of specific needs and conditions guides the selection process.

HOW DOES INSULATION IMPACT SOLAR PIPE PERFORMANCE?

The impact of insulation on solar pipe performance cannot be overstated. Effective insulation significantly minimizes heat loss from pipes, ensuring that hot fluid retains its temperature as it travels from the solar collectors to the storage tanks or usage points. Without adequate insulation, considerable heat energy can dissipate, particularly in colder climates, leading to decreased efficiency and higher energy demands for heating. Proper insulation materials, such as polyurethane foam or fiberglass, provide a barrier against thermal escape, ensuring that energy capture efficiencies remain optimal. Additionally, insulation safeguards pipes against the risk of freezing in colder seasons, thereby preventing potential bursts that could disrupt system operation. Therefore, insulation is a critical component of the overall design of solar heating systems, directly influencing operational efficiency and system longevity.

WHAT AFFECTS THE LIFESPAN OF SOLAR PIPES?

The lifespan of solar pipes is influenced by several factors, including material choice, environmental conditions, and installation practices. Copper pipes are renowned for their durability, often lasting several decades when properly installed and maintained; they resist corrosion and degradation under high temperatures. However, external factors, such as galvanic corrosion and water quality, can impact their longevity. Conversely, PEX pipes, while durable, are sensitive to UV exposure and can degrade when subjected to direct sunlight without protection. Proper installation techniques also play a crucial role; poorly installed pipes may face risks of leaks, which can lead to significant damage over time. Regular maintenance and inspections ensure that potential issues are identified early, thereby extending the effective lifespan of the piping system. In summary, a combination of material quality, environmental factors, and maintenance practices determines how long solar pipes will function effectively within a given system.

The selection of piping for solar installation is a nuanced decision requiring careful consideration. Choosing the right pipes involves evaluating factors such as material properties, thermal performance, environmental conditions, and the requirements of the solar system. Copper and PEX have established positions in the industry, each offering distinct advantages and limitations. These choices directly impact efficiency, reliability, and the overall performance of solar installations. To maximize effectiveness, it is essential to assess all variables and select materials aligned with the specific objectives of the solar project at hand, ensuring a sustainable and efficient energy future. Through continued innovation and adaptation, piping choices in solar technology will continue to evolve, reflecting advancements in both material science and design practices.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-kind-of-pipes-are-used-for-solar-installation/