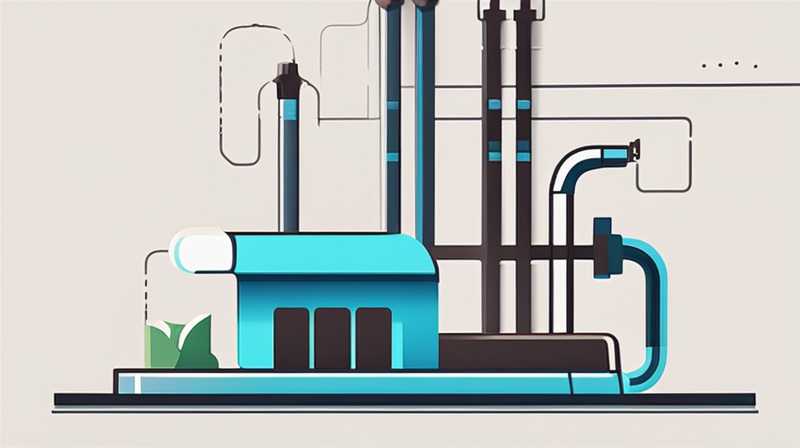

To effectively harness solar energy, specific types of pipes are essential: 1. Hot water pipes for transporting heated water, 2. Solar collector pipes for drawing heat energy from the sun, 3. Insulated pipes to minimize heat loss, 4. Drainback system pipes for draining fluid in case of system shutdown. Hot water pipes are particularly important as they need to withstand high temperatures while maintaining the flow of water. These pipes must be made from durable materials to endure the elements and higher pressure, ensuring the efficiency and longevity of the solar system.

1. TYPES OF PIPES USED IN SOLAR ENERGY SYSTEMS

In solar energy systems, various types of pipes serve particular functions. These pipes ensure the effective collection, transportation, and distribution of solar-heated fluids. Hot water pipes, solar collector pipes, insulated pipes, and drainback system pipes are some of the critical components in the design of solar heating systems.

Hot water pipes are crucial as they transport water from the solar collectors to storage tanks. Typically, they are constructed from materials that can endure high temperatures and pressures, such as copper, stainless steel, or PEX (cross-linked polyethylene). The choice of material will depend on several factors, including cost, longevity, pressure rating, and thermal conditions. Adequate insulation is equally important to ensure minimal heat loss during transportation. An effective insulation layer can significantly improve the overall efficiency of the solar heating system.

Solar collector pipes play another vital role in the functionality of solar energy installations. They are designed to collect heat from the sun and transfer it to the fluid circulating through the system. Materials such as copper are often preferred due to their superior thermal conductivity, enabling optimal heat transfer. Different methods exist to integrate these pipes into various types of solar collectors, whether they are flat panel, evacuated tube, or concentrating collectors. The design of these pipes must align with the overall solar thermal system to ensure maximum energy capture.

2. INSULATION REQUIREMENTS FOR PIPES

The insulation of pipes is one of the most pivotal aspects of a solar energy system. Insulating the pipes not only reduces heat loss but also helps maintain the efficiency of energy transfer. Insulated pipes are usually coated with materials such as foam, fiberglass, or reflective sheeting to achieve this goal.

The use of insulation in piping serves two primary functions. Firstly, it minimizes the thermal losses that occur during the transportation of heated water. As the hot water traverses through pipes, any heat lost can directly impact the system’s efficiency. Secondly, insulation ensures that the temperature of the fluid is maintained, allowing it to remain effective during colder months or in regions with fluctuating temperatures. The correct insulation can lead to lower energy consumption and more reliable heating, thus making the system more cost-effective over time.

Selecting the appropriate level of insulation is critical and depends on various factors, including outdoor temperature, energy content needed, and the nature of the installation. A thorough analysis of these elements allows for tailored solutions that optimize the entire solar energy system.

3. SPECIFICATIONS FOR DRAINBACK SYSTEM PIPES

When discussing solar energy systems, drainback systems offer a unique advantage, especially in cooler climates. These systems utilize drainback pipes designed to return the fluid back to the storage tank when it is not required, such as during the night or when temperatures drop.

The design of drainback pipes must support gravity flow efficiently and is usually characterized by a larger diameter than standard pipes to minimize resistance. Moreover, the materials utilized must withstand various conditions in which they could be emptied and refilled repeatedly. Durability is paramount in these pipes since they undergo frequent cycling, which can cause wear and tear.

Overall, the drainback system presents versatility in solar installations and protects the system components from freezing conditions. This adaptability is essential for seasonal climates, as it ensures continuous heating throughout the year without significant risk of damage.

4. CONSIDERATIONS FOR MATERIAL CHOICE

When selecting materials for the pipes in solar energy systems, several factors come into play. Durability, thermal performance, cost, and environmental impact are paramount considerations in the decision-making process. The chosen material must perform reliably under high temperatures and pressures while resisting corrosion.

Copper is a common choice due to its excellent heat conductivity and long lifespan. Its downside, however, is higher costs and susceptibility to certain types of corrosion unless properly treated. Stainless steel presents a robust alternative that thrives in harsher environments, though it may be more expensive than other materials.

PEX, on the other hand, has gained popularity in recent years. Its lightweight, flexible features and resistance to corrosion make it attractive for a wide variety of solar heating configurations. Furthermore, PEX has a lower initial cost and installation time. However, the temperature limitations of PEX must be carefully considered, particularly in high-temperature applications where other materials may excel.

5. INSTALLATION TIPS AND BEST PRACTICES

When implementing a solar energy system, installation is a pivotal phase that determines the effectiveness and lifespan of the components. Professionals must ensure that the chosen pipes are installed correctly to avoid potential failures and inefficiencies. Each type of pipe serves a specific purpose within the system and must be connected in accordance with best practices.

Professional installation is often recommended. Specialists possess the expertise to evaluate the design of the solar energy system. They can recommend the best pipe materials and installation techniques to ensure reliability and efficiency. Additionally, inspecting existing piping connections, material transitions, and overall layout can eliminate issues before they arise, significantly decreasing maintenance requirements.

Moreover, adhering to local building codes and regulations is critical during installation. Certain regions may require specific classes of materials or configurations to enhance safety and environmental sustainability. Compliance ensures effective and legally accepted usage of solar energy systems.

FREQUENTLY ASKED QUESTIONS

WHAT MATERIALS ARE BEST FOR SOLAR ENERGY PIPES?

The selection of materials for pipes in solar energy systems involves several important aspects: durability, thermal performance, cost-effectiveness, and environmental implications. Commonly used materials include copper, stainless steel, and PEX (cross-linked polyethylene). Each material has distinct properties that influence its suitability for specific applications. Copper is favored for its excellent thermal conductivity and longevity but has higher costs and is prone to corrosion if not adequately protected. Stainless steel is highly durable and resistant to corrosion, making it ideal for harsh environments, albeit at a premium price. PEX has gained traction due to its flexibility, corrosion resistance, and lower installation costs, even though it may have limitations in high-temperature settings. Making the right choice often depends on the specific requirements of the solar installation site, budget constraints, and expected environmental conditions.

HOW DOES INSULATION AFFECT SOLAR ENERGY SYSTEMS?

Insulation plays a crucial role in solar energy systems by reducing heat loss and maximizing efficiency. Insulated pipes help retain the thermal energy of the fluid being transported, ensuring that it arrives at its destination at the highest possible temperature. This is particularly important in regions where significant temperature fluctuations occur, as heat loss directly impacts the system’s overall efficiency, leading to increased energy consumption to maintain optimal temperatures. The right insulation materials, such as foam or fiberglass, can help minimize this loss, reducing operational costs over time. Therefore, investing in proper insulation not only enhances the performance of solar energy systems but also contributes to their longevity and sustainability.

WHAT IS A DRAINBACK SYSTEM AND HOW DOES IT WORK?

A drainback system is a type of solar energy configuration designed to mitigate the risks associated with freezing and overheating. It utilizes specially designed drainback pipes that enable the fluid to drain back into the storage tank or a reservoir when there is no demand for heating, especially during nighttime or cold weather conditions. This functionality prevents the fluid from freezing in the pipes, which can lead to costly damages and system failures. During the day, when the solar collectors are producing heat, the system allows the fluid to flow back into the collectors, effectively collecting heat energy from the sun. The drainback design ensures that the solar energy system remains effective and operational over a wider range of seasonal conditions, making it especially useful in climates with cold temperatures.

The implementation of appropriate piping systems in solar energy installations is imperative for operational efficiency and longevity. Choosing suitable materials, insulating effectively, and designing with precision can dramatically impact overall performance. Hot water pipes, solar collector pipes, insulated pipes, and drainback system pipes all serve integral functions that contribute to the complete functionality of solar systems. Attention to detail in material selection and installation techniques assists users in maximizing the potential benefits derived from solar technologies. Each element, from thermal conductivity to seasonal adaptability, serves a purpose that, when combined proficiently, will yield a reliable and efficient solar energy solution capable of meeting diverse energy needs. In a world increasingly reliant on sustainable energy sources, understanding and implementing the correct pipe systems for solar applications is not just beneficial but essential for the future. Investing in such infrastructure promises long-term returns both financially and environmentally, advocating a more sustainable way forward in energy consumption.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-kind-of-pipes-are-needed-for-solar-energy/