1. WIRE MATERIAL OF SOLAR BARRELS, 2. COMMON TYPES OF WIRE, 3. FUNCTIONAL SIGNIFICANCE, 4. CHALLENGES IN WIRE USAGE

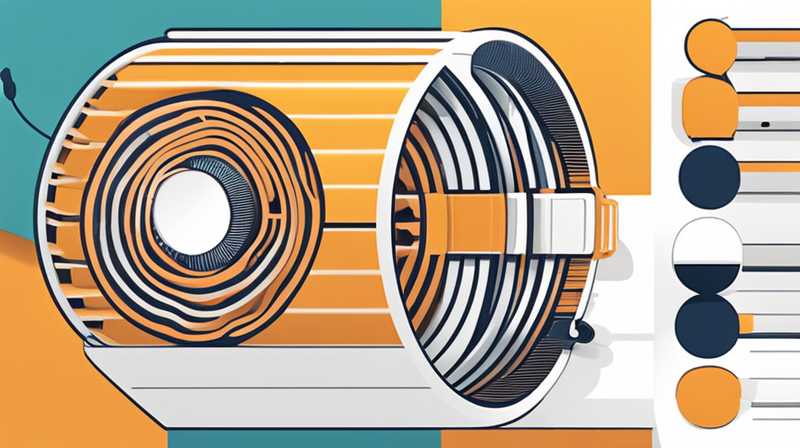

The wire inside a solar barrel primarily serves as a crucial component in the operation and efficiency of solar systems. 1. Conductive metals like copper are predominantly utilized, given their superior electrical conductivity and resistance to corrosion. 2. Aluminum serves as a lighter alternative, often employed for specific applications where weight savings are critical. 3. These wires are typically insulated to prevent electrical losses, ensuring that energy harnessed from solar panels is transmitted effectively through the system. Among these, copper wires are favored for their long-term durability, resistance to oxidation, and ability to maintain performance across temperature variations.

Understanding the types and characteristics of wires within solar barrels is essential for maximizing efficiency in solar energy systems. The choice of wire is critical as it affects the system’s overall performance, installation ease, and long-term reliability.

1. WIRE MATERIAL OF SOLAR BARRELS

When examining the construction of solar barrels, one encounters several materials that are pivotal to their function. Typically, copper is the wire material of choice due to its exceptional conductivity. This characteristic is crucial for minimizing energy loss during transmission. Unlike other metals, copper maintains its electrical properties across a wide range of temperatures. As a result, it is particularly well-suited for outdoor applications where temperature fluctuations are common.

Moreover, the presence of high-purity copper tends to enhance the longevity of these wires by significantly reducing the chances of oxidation. Oxidation can lead to increased resistance, thereby diminishing overall efficiency. Technically, the thickness of the wire used in solar barrels must also be considered. A thicker gauge wire may handle a higher current, thus allowing for more efficient energy flow. Consequently, the selection of wire material and thickness can profoundly influence the operational efficacy of a solar energy system.

2. COMMON TYPES OF WIRE

Aside from copper, aluminum wires are prevalent in solar applications. These wires are appreciated for being lightweight and more affordable when compared to copper. Nevertheless, aluminum does possess slightly lower conductivity, which is an important factor to consider. Typically, manufacturers may employ aluminum in larger-scale installations where minimizing weight is crucial. These wires are also often used in conjunction with other materials, employing aluminum strands coated with a thin layer of copper to enhance conductivity.

Another emerging material is tinned copper, which has a layer of tin plating. This innovative approach combines the benefits of both metals, assisting in corrosion resistance while also improving conductivity. Such advancements in wire technology are instrumental in addressing some common challenges associated with outdoor installations. The choice of wire ultimately reflects a balance of performance, cost, and installation requirements.

3. FUNCTIONAL SIGNIFICANCE

At the core of solar energy systems lies the functionality provided by the wiring inside solar barrels. The role of these wires goes beyond mere energy transmission; they are integral to the overall efficiency of the solar collection and utilization process. Properly functioning wires ensure that every unit of energy captured by the solar panels is efficiently delivered to the inverter and subsequently to the grid or storage systems.

When solar panels absorb sunlight, they convert it into direct current (DC) electricity. The wires transmit this electricity to an inverter, where DC electricity transforms into alternating current (AC) electricity for use in homes or businesses. Hence, if the wiring is substandard or improperly installed, it can lead to energy losses, impacting the system’s total output. Additionally, the insulation of these wires prevents shorts and safeguards against environmental exposure.

4. CHALLENGES IN WIRE USAGE

Despite advancements in wire technology, challenges persist in utilizing wires within solar barrels. One significant issue relates to the effects of thermal expansion and environmental fluctuations. As temperatures increase, different materials expand at varying rates, which can lead to stress on connections and subsequent failures.

Furthermore, the potential for galvanic corrosion must be addressed when different metals, such as copper and aluminum, are combined. This phenomenon occurs when two dissimilar metals are in contact within the presence of moisture, leading to deterioration of one of the metals. Manufacturers often design specific connectors and junction boxes to mitigate these risks; however, the choice of materials and installation methods plays a significant role in preventing long-term issues.

Moreover, regulatory compliance can also pose challenges in the selection and usage of wire for solar applications. Adhering to local codes and standards is vital to ensure safety and longevity. Any lapses in this area can lead to suboptimal performance or even jeopardize the system’s safety and reliability.

FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF WIRE ARE USED IN SOLAR BARRELS?

Various conductors are employed in solar barrels, primarily copper and aluminum. Copper wires are favored due to their exceptional conductivity and durability, whereas aluminum, being lighter and more economical, is often chosen for larger installations. In some cases, tinned copper wires are used to combine the advantages of both materials, ensuring maximum performance while minimizing corrosion risks.

HOW DOES THE WIRE AFFECT SOLAR PANEL PERFORMANCE?

The choice of wire plays a crucial role in the efficiency of a solar panel system. High-quality, appropriately sized wires minimize electrical resistance, thus allowing for more efficient energy transmission from the solar panels to the inverter. Any deficiencies in the wire quality or improper installation can lead to energy losses, significantly affecting overall performance and the amount of energy generated.

ARE THERE ENVIRONMENTAL FACTORS THAT IMPACT WIRE USAGE?

Yes, environmental elements such as temperature fluctuations, moisture, and atmospheric conditions significantly affect the performance and longevity of wire used in solar barrels. Materials must be chosen to withstand these conditions and avoid issues like corrosion or thermal expansion. Special insulating materials and protective coatings can enhance resilience, but attention to installation practices is vital in preventing deterioration over time.

In summary, the wires within solar barrels represent a crucial element of solar energy systems, impacting both efficiency and durability. The predominant materials, such as copper and aluminum, each offer unique benefits suited to different applications. As the solar industry evolves, innovations in wire technology continue to enhance energy systems—addressing both efficiency and sustainability. The importance of wire selection cannot be overstated; it forms the backbone of energy transmission and the overall efficacy of solar installations. Thus, careful consideration of wire materials, their characteristics, and the environmental factors influencing performance is essential for optimizing solar power technology. Understanding these elements ensures that solar systems contribute effectively to sustainable energy goals while minimizing long-term operational challenges.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-the-wire-inside-the-solar-barrel/