1. The material of a solar cylinder primarily consists of high-quality glass, aluminum, and sometimes polymers, ensuring optimal performance and durability. 2. Glass is used for the outer shell due to its excellent transparency and resistance to environmental factors. 3. Aluminum is often employed for the frame, providing robustness and lightweight characteristics. 4. The materials used ensure efficient heat retention and energy transfer.

MATERIAL SELECTION IN SOLAR CYLINDERS

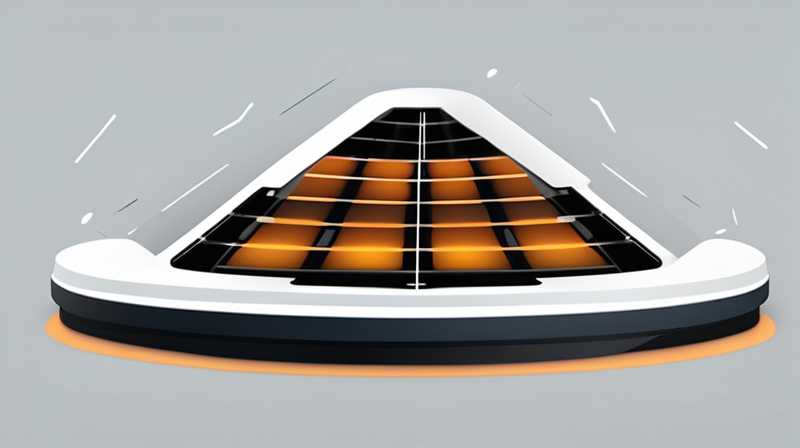

In the realm of solar energy technology, particularly concerning solar water heating systems, the choice of materials within solar cylinders plays a pivotal role. Solar cylinders are structured to harness sunlight and convert it into heat efficiently. The combination of materials must ensure that energy is not only captured effectively but also retained over a sustained period. This involves a careful selection of components, including the outer casing, the internal structure, and the heat-retaining substances incorporated into the design.

GLASS IN SOLAR CYLINDERS

High-quality glass serves as the primary exterior material in many solar cylinders, contributing significantly to the functionality of these devices. The transparency of glass allows maximum solar radiation to penetrate and reach the internal components. Additionally, advancements in glass technology have introduced options such as tempered glass, which enhances durability and resistance to various weather conditions. Tempered glass is known for its ability to withstand temperature fluctuations and external impacts, a crucial factor considering that solar cylinders are often placed outdoors.

Moreover, the specific coatings applied to the glass surface can further enhance its effectiveness. Low-emissivity (Low-E) coatings help minimize heat loss during colder periods while maximizing solar gain. This technology contributes to improved energy efficiency and better operational performance, allowing the solar cylinder to maintain higher temperatures for longer durations.

ALUMINUM FRAMEWORK

The structural integrity and support for solar cylinders often stem from aluminum components. Aluminum is prized in the construction of solar cylinders due to its lightweight nature and exceptional resistance to corrosion. This characteristic is particularly advantageous for outdoor installations, where exposure to moisture and chemicals can compromise less resilient materials. The aluminum framework provides the necessary rigidity while ensuring that the overall weight of the assembly remains manageable for installation and maintenance.

In addition to structural aspects, aluminum is also effective in facilitating heat dissipation. The thermal conductivity of aluminum allows for efficient heat distribution within the solar cylinder, promoting better energy transfer. Consequently, the combination of aluminum’s lightweight features and its thermal properties makes it an ideal choice for solar technology.

POLYMERS AS ALTERNATIVES

In some modern designs, polymers are being integrated into solar cylinder construction. Materials such as high-density polyethylene (HDPE) or polycarbonate are being used for specific components due to their impressive resilience and cost-effectiveness. Polymers can provide enhanced flexibility and are easier to mold into various shapes compared to traditional materials, allowing for innovative designs that traditional materials might constrain.

Moreover, polymers often exhibit good insulation properties. Incorporating polymers can reduce thermal bridging in assemblies, improving heat retention further. This material choice not only improves the efficiency of the solar cylinder but also allows for a degree of aesthetic customization that traditional materials may not provide. As the industry progresses, the use of innovative materials will likely expand, leading to progressively efficient solar thermal systems.

THERMAL INSULATION PROPERTIES

The efficiency of a solar cylinder is significantly influenced by its thermal insulation capabilities. The right selection of insulation materials, particularly around the cylindrical structure, prevents heat loss and enhances performance. Common insulation materials used in conjunction with glass and aluminum include polyurethane foam and fiberglass, both known for their low thermal conductivity.

Polyurethane foam is particularly valued for its high R-value per inch, meaning it offers impressive insulation performance even at thinner widths. This insulation traps heat within the cylinder and ensures that water maintains a high temperature for extended periods, especially during nighttime. Conversely, fiberglass, while being less effective than polyurethane in absolute terms, still provides a good balance of insulation and cost-effectiveness.

APPLICATIONS AND EFFICIENCIES

Understanding the optimal materials for solar cylinders extends beyond mere construction; it branches into applications and efficiencies, influencing various sectors. From residential hot water systems to large-scale solar thermal power plants, the choice of materials can affect not only performance but scalability and sustainability. Each application has different heating needs, which can dictate the specific materials selected.

Furthermore, efficiency standards are becoming stricter, and manufacturers are compelled to adopt materials that not only meet energy output expectations but also minimize environmental impacts. Innovations such as recyclable materials and those sourced from sustainable practices are becoming prominent, ensuring that the industry moves towards greater accountability in material selection. As such, the dynamics of material utilization in solar cylinders remain an evolving field, reflective of both technological advancements and environmental consultancy.

CONSIDERATIONS FOR MATERIAL SELECTION

When delving into material choices for solar cylinders, several factors warrant attention. Longevity, efficiency, cost, and environmental impact are critical drivers that guide material selection. It is important to evaluate how all components work in conjunction, providing a balanced approach to performance and durability.

For manufacturers, ensuring a balanced selection that mitigates weaknesses found within other materials further enhances the integrity of solar cylinder designs. For instance, using glass in combination with aluminum frames provides a resilient and efficient product, maximizing advantages while minimizing defects. The comprehensive evaluation of materials paves the path for creating superior solar thermal systems that meet increasing consumer demands.

STANDARDS AND CERTIFICATIONS

As the industry adapts to advancements, adherence to standards and certifications becomes paramount in material selection. Compliance with regulations ensures that solar cylinders not only perform well but also meet safety and environmental guidelines. In many regions, various agencies set benchmarks that materials must achieve to secure product warranties and certifications, further ensuring consumer trust.

Additionally, certification programs often focus on testing materials under extreme conditions to gauge longevity and reliability. Such initiatives ensure that products offered in the market align with claims made by manufacturers regarding efficiency, safety, and environmental impact. Prospective buyers should verify that the cylinders they consider purchasing comply with relevant standards, ensuring that both performance and sustainability are taken into account.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE BENEFITS OF USING GLASS IN SOLAR CYLINDERS?

The integration of glass in solar cylinders brings forth an array of advantages that enhance performance and durability. Firstly, glass possesses high transparency, allowing for optimal sunlight penetration. This characteristic helps to maximize heating efficiency, ensuring that more sunlight is captured and converted into usable thermal energy. Additionally, the use of tempered or Low-E glass provides strength against environmental impacts while also serving to minimize heat loss during the night or cooler periods.

Furthermore, glass barriers remain inert when exposed to various chemicals and temperatures, ensuring that the material does not degrade over time. This resistance increases the lifespan of the solar cylinder, which is critical for consumers looking to make long-term investments. Overall, the inclusion of glass within solar cylinder design addresses both efficiency and durability concerns, making it a fundamental choice for manufacturers.

WHY IS ALUMINUM PREFERABLE IN SOLAR CYLINDER CONSTRUCTION?

Aluminum is predominantly selected for solar cylinder frames due to its unique blend of properties that promote both functionality and aesthetics. It is lightweight yet sturdy, making handling and installation processes straightforward. As a construction material, aluminum offers significant resistance to corrosion, a vital attribute given that solar cylinders frequently endure exposure to moisture and various environmental elements.

Moreover, aluminum’s thermal conductivity facilitates efficient heat distribution within the cylinder during operation. This characteristic is particularly beneficial in optimizing performance, especially in designs that require rapid heat transfer. In summary, aluminum contributes significantly to the overall efficacy and longevity of solar cylinders, and its properties make it an optimal choice in solar technology applications.

CAN POLYMERS REPLACE TRADITIONAL MATERIALS IN SOLAR CYLINDERS?

The emergence of polymers within solar cylinder construction introduces exciting possibilities for future designs. While traditional materials like glass and aluminum have established track records, polymers offer flexibility and versatility that promote innovative designs. For instance, polymers such as high-density polyethylene (HDPE) can aid in creating more ergonomic shapes and lightweight structures that adapt to diverse applications.

Additionally, many polymer formulations demonstrate excellent insulation properties, effectively reducing heat loss and enhancing overall system efficiency. These benefits, combined with the potential for cost efficiency, suggest that polymers may complement traditional materials rather than completely replace them. As the industry continues to innovate, the integration of polymers alongside classic materials will likely define the next generation of solar cylinders.

SYNTHESIZING THE IMPACT OF MATERIAL CHOICE IN SOLAR CYLINDERS

When evaluating solar cylinders and the materials utilized therein, it is essential to recognize the critical interplay of different components, each contributing to overall performance. The materials selected—glass for transparency, aluminum for structural integrity, and polymers for innovation—all factor into how well these systems fulfill their purpose of harnessing and storing solar energy.

The choices made during the manufacturing process not only impact operational efficiency but also sustainability and environmental responsibilities. As technology progresses and consumer demands shift, the exploration into optimal materials remains vital for driving advancements within the solar industry. Future developments will likely reflect both heightened performance standards and a commitment to sustainable practices, influencing consumer decision-making and industry growth.

Furthermore, as competition enlarges within this sector, understanding the nuances of materials will guide manufacturers to innovate thoughtfully by integrating cutting-edge solutions while adhering to traditional practices. A holistic approach to material selection will amplify the potential of solar energy systems while ensuring they align with both market expectations and environmental imperatives. Thus, the materials of solar cylinders are more than mere components; they represent a microcosm of the broader shifts within renewable energy technology.

In summary, the material composition of solar cylinders critically influences operational success, durability, and alignment with sustainability goals. By recognizing the advantages of each material, stakeholders can make informed decisions that optimize performance and longevity in their solar solutions. Through a careful marriage of innovation and tradition, the future of solar energy systems will be shaped by these insightful material choices.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-the-material-of-the-solar-cylinder/