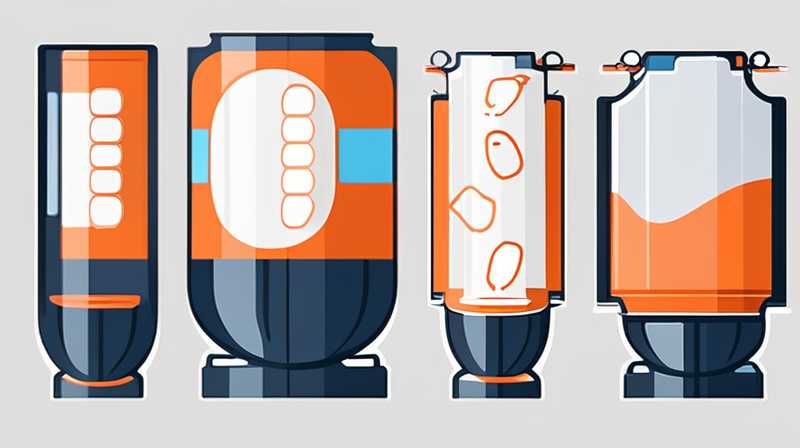

The inner liner of a solar thermal barrel refers to the component designed to enhance heat retention and improve energy efficiency in solar water heating systems. 1. The inner liner serves as a protective barrier between the water and the heat-absorbing surface, 2. It is typically made from materials such as polyethylene or aluminum, 3. This liner plays a crucial role in heat transfer, and 4. Its design influences the efficiency of the solar thermal system significantly. The selection of the liner material impacts not only the durability but also the performance of the solar thermal barrel, particularly in varying environmental conditions. Understanding the composition, construction, and operational significance of the inner liner is essential for optimizing solar thermal systems for maximum energy capture and retention.

1. IMPORTANCE OF INNER LINER MATERIAL

When discussing the inner layer of solar thermal barrels, it is essential to recognize that the choice of material is pivotal in ensuring optimal performance. The inner liner directly affects heat retention and system efficiency. Generally, polyethylene is favored due to its lightweight nature, affordability, and excellent thermal resistance. Additionally, aluminum liners offer impressive heat conductivity, thereby enhancing thermal transfer.

Moreover, different materials provide varying resistance to corrosion, which is crucial for longevity. For instance, while polyethylene can be subject to wear over time due to UV exposure, aluminum’s inherent properties shield it from some degradation. The construction of the liner might also include a reflective coating that maximizes solar energy absorption. Through diligent material selection, efficiency can be greatly impacted, and this choice contributes to the overall functionality of the solar thermal barrel. The optimal material ensures that the water heats rapidly while minimizing heat losses, which is crucial for the effectiveness of any solar thermal system.

2. THERMAL PERFORMANCE OF THE INNER LINER

Another critical aspect to consider is how the design of the inner liner contributes to thermal performance. Optimal design considers both the thickness and the surface texture of the liner. A thicker liner can provide better insulation, preventing heat loss. On the other hand, the surface texture may enhance the interaction between the liner and the water, facilitating better heat transfer.

The liner’s configuration may also influence the water flow within the barrel. A well-designed inner liner can ensure uniform heat distribution, preventing hot and cold zones that could otherwise hinder effectiveness. Maintaining a consistent temperature throughout the storage tank is vital for maximizing energy use. The liner’s design not only needs to prioritize heat retention but also needs to accommodate expansion as water heats up. Essentially, thermal performance is about finding the intersection of material properties, design efficiency, and intentional engineering principles that promote optimal energy use. Effective design can significantly streamline performance, setting the stage for an energy-efficient solar thermal barrel.

3. IMPACT ON ENERGY EFFICIENCY

The inner liner of a solar thermal barrel plays a fundamental role in the system’s overall energy efficiency. When evaluating energy efficiency, both the functionality and management of heat are paramount. An effective inner liner minimizes energy losses and maximizes heat retention, which is essential for the efficiency of the entire solar thermal system.

Furthermore, advancements in insulation technology have encouraged the integration of materials that enhance performance. For example, vacuum-insulated liners can drastically reduce heat loss compared to conventional liners. These advanced materials retain heat significantly longer, thus improving the overall system efficiency. Additionally, professional installation and proper fittings can minimize air gaps between the liner and other components, which can compromise efficiency. Ultimately, energy efficiency isn’t merely about the technical specifications of parts; it also encompasses how well they work together under various conditions and stresses. In essence, the inner liner significantly contributes to energy savings by efficiently managing heat relationships within the solar thermal barrel.

4. INSTALLATION CONSIDERATIONS

When it comes to the practical aspects of solar thermal barrel implementation, installation can profoundly impact the inner liner’s performance. Professional installation minimizes errors and optimizes the liner’s potential. Misalignment can lead to gaps that allow heat to escape, counterproductive to a system built for efficiency. Therefore, engaging installation experts can assure that all components fit correctly, and all elements of the inner liner are sustained without compromise.

Moreover, it is pivotal to consider the operational environment when installing the solar thermal barrel. Liner materials must withstand regional climatic conditions. For instance, certain materials perform better in cold climates, while others are preferable in hot conditions. Installation site selection should also account for potential shading that might diminish solar gain. Ultimately, ensuring that the inner liner is correctly installed and suited to environmental conditions maximizes both durability and performance, ensuring long-lasting efficiency in energy use.

5. MAINTENANCE AND LONGEVITY OF THE INNER LINER

Proper maintenance can extend the life expectancy of the inner liner significantly, preserving its integrity and ensuring optimized performance over time. Regular maintenance routines should include inspecting for leaks, corrosion, and build-up of minerals that could impede performance. Addressing these issues promptly can reduce the chances of severe damage resulting in costly repairs or system replacements.

Furthermore, periodic cleaning of the inner liner can help maintain its thermal properties. Mineral build-up or sediment can insulate and restrict heating, ultimately affecting the barrel’s overall efficiency. Utilizing the appropriate cleaning solutions and methods is critical in this process. Ultimately, a carefully devised maintenance schedule involving inspection, cleaning, and prompt repairs will optimize the lifespan and functionality of the inner liner, ensuring it serves efficiently for many years.

COMMONLY ASKED QUESTIONS

WHAT ARE THE MOST COMMON MATERIALS USED FOR THE INNER LINER OF SOLAR THERMAL BARRELS?

Common materials employed for the inner lining of solar thermal barrels include polyethylene and aluminum. Polyethylene is highly favored due to its cost-effectiveness and reasonable insulation properties, while aluminum offers superior thermal conductivity but may require a coating to prevent corrosion. In addition, some modern systems adopt multilayered structures that incorporate a variety of materials providing insulation, thermal retention, and durability. This combination maximizes the advantages of each material, ensuring that the inner liner performs effectively under a wide range of operational conditions. Understanding the materials utilized helps in making informed decisions about which solar thermal barrel best suits specific needs, thereby influencing overall system performance.

HOW DOES THE INNER LINER AFFECT HEAT RETENTION IN SOLAR THERMAL BARRELS?

The inner liner significantly influences heat retention in solar thermal barrels. A well-designed liner prevents heat escape through effective insulation. By utilizing materials with low thermal conductivity, manufacturers can ensure that water maintains its temperature for longer periods. Additionally, liners featuring reflective properties can enhance absorption by efficiently channeling heat into the water. The thickness and material choice further influence the overall thermal retention, as thicker liners typically provide better insulation when installed correctly. By maintaining a consistent temperature, energy consumption can be minimized, making the system more efficient. Understanding the thermal dynamics involved emphasizes the importance of the inner liner in optimizing solar thermal barrel performance.

WHAT MAINTENANCE IS REQUIRED FOR THE INNER LINER OF A SOLAR THERMAL BARREL?

Regular maintenance is crucial for the inner liner of a solar thermal barrel to maintain performance and longevity. Inspection should focus on potential leaks, corrosion, and mineral deposits that could hinder efficiency. Establishing an annual or bi-annual maintenance schedule is advisable to identify issues before they escalate. Additionally, comprehensive cleaning routines will ensure the liner remains free from debris and mineral build-up, which can act against heating efficacy. Professional inspections may also ascertain that installation remains intact and operational requirements are met. Keeping the inner liner well-maintained directly correlates with the overall performance of the solar thermal system, making these maintenance efforts worthwhile for optimizing energy efficiency.

Understanding the inner liner’s critical role in solar thermal barrels involves acknowledging the myriad factors impacting its efficiency and performance. Material selection, thermal properties, installation, and maintenance are all pivotal elements that contribute to a system’s overall effectiveness. When integrated thoughtfully, these factors ensure that energy capture is maximized, and operational longevity is achieved, cementing the significance of the inner liner in solar thermal technology. Additionally, as advancements in materials and installations evolve, this area is poised for further innovations that may shift the current paradigms of solar thermal efficiency. Therefore, ongoing research and adaptation will continue to enhance the functionality of these systems, ensuring they meet the growing energy demands of today and the future. With a concerted focus on these components, solar thermal barrels can play an even more substantial role in sustainable energy solutions, benefitting both individual installations and broader renewable energy initiatives.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-the-inner-liner-of-the-solar-thermal-barrel/