What is the gas pressure of the energy storage device?

1. The gas pressure within an energy storage device is crucial for its operation, and it can vary significantly depending on several factors: 2. It typically ranges between 1 to 30 bar in many applications, heavily influenced by the type of technology employed; 3. In compressed gas systems, higher pressures correlate with increased energy density; 4. Understanding these parameters is essential for efficiency, safety, and performance optimization.

UNDERSTANDING GAS PRESSURE IN ENERGY STORAGE DEVICES

The Role of Gas Pressure in Energy Storage Systems

Gas pressure plays a pivotal role in the operation and efficiency of various energy storage devices. These systems often operate by storing energy in a gaseous state, compressing air or other gases to facilitate energy release when needed. Whether it pertains to compressed air energy storage (CAES) or gas-filled storage systems, understanding the intricacies of gas pressure is essential for optimizing performance.

Within these systems, the specific gas pressure must be finely calibrated to manage both energy efficiency and safety. For instance, when the gas is compressed, it can store potential energy, which is released through turbines or other mechanisms for energy conversion. The efficiency of energy transfer directly correlates to the pressure levels maintained within the reservoir. As such, engineers must adhere to strict guidelines to ensure that pressure levels are appropriate for the specific technology employed.

Variability of Gas Pressure in Various Technologies

The gas pressure in energy storage devices does not adhere to a singular standard but instead varies significantly across different technologies utilized. Compressed Air Energy Storage (CAES) typically operates under pressures ranging from 1 to 30 bar, or even higher in advanced systems. This variability is attributable to design considerations, such as the size of the compression chamber and the intended energy output.

Another relevant context to consider is the function of the energy storage device. For instance, balmy slab systems that leverage hydrogen as a storage medium must maintain suitable pressure for the gas to remain in a liquid state at ambient conditions. Thus, it can be observed that the integration of gas pressure within energy storage technologies is multi-faceted, affecting overall system design and functionality. This delineation of gas pressure across technologies illustrates the nuanced approaches necessary for different applications.

OPTIMIZATION OF GAS PRESSURE

Techniques for Managing Gas Pressure

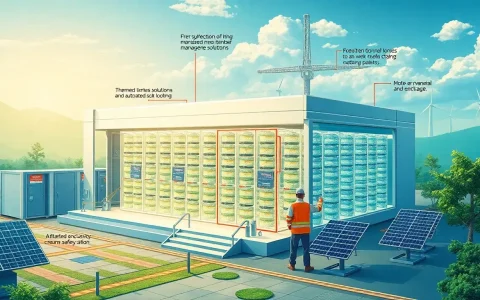

To achieve optimal gas pressure within energy storage devices, a range of techniques and methodologies must be implemented. Monitoring and control mechanisms play an integral role in this process, ensuring that pressure levels remain within safe and functioning parameters. Pressure relief valves, for instance, are crucial components for preventing over-pressurization, which can lead to system failures or safety hazards.

In addition, the engineering design of the storage system itself can greatly influence gas pressure management. Utilizing advanced materials that can withstand high pressures without deforming is essential for maintaining system integrity. Moreover, implementing feedback loops enables continuous measurement and adjustment to maintain the desired pressure levels throughout operation. Through these strategies, energy storage systems can achieve enhanced performance while minimizing risks associated with pressure irregularities.

The Impact of Temperature on Gas Pressure

Gas pressure is intricately linked to temperature, according to the principles of thermodynamics. An increase in temperature generally leads to an elevation in gas pressure, which is a critical aspect that must be managed in energy storage contexts. For energy storage devices functioning under variable environmental conditions, ensuring temperature regulation is paramount for maintaining optimum gas pressure.

Effective insulation and cooling systems aid in moderating temperature changes within storage units. This attention to thermal management directly enhances the reliability of the gas pressure, ensuring that the energy storage device operates efficiently. In places where temperature fluctuations are prevalent, design choices that accommodate such variations become essential in preserving the integrity of the stored energy. Thus, the relationship between temperature and gas pressure is an indispensable factor in enhancing the longevity and functionality of energy storage devices.

SAFETY CONSIDERATIONS

Risks Associated with High Gas Pressure

While gas pressure is essential for energy storage efficiency, elevated pressure levels also carry inherent risks. Safety protocols must be established and strenuously followed to mitigate hazards related to high-pressure systems. The potential for catastrophic failure exists if systems are not diligently monitored and maintained, necessitating comprehensive risk assessments.

One common issue arises from the wear and tear of valves and seals that contain gas pressure. Over time, these components can become compromised, leading to leaks or sudden depressurization. Regular inspections and maintenance schedules are crucial to ensuring that these failures do not occur. Establishing clear operational guidelines allows for a thorough understanding of safe pressure limits. In this respect, risk management associated with gas pressure is a critical aspect of efficient energy storage system operations.

Regulatory Standards and Compliance

Energy storage devices must comply with various regulatory standards concerning gas pressure. In many regions, authorities implement rigorous guidelines to ensure safety for both operators and the general public. Understanding and adhering to these regulations is not merely a recommendation; it is an obligation for operators within the energy sector.

These standards often dictate permissible pressure limits, safety equipment requirements, and monitoring practices, ensuring that energy storage facilities operate within safe parameters. Additionally, compliance with these regulations supports public trust in energy storage solutions by emphasizing safety and reliability. Therefore, navigating the landscape of regulatory compliance is fundamental for organizations wishing to operate in the energy storage sector.

ECONOMIC IMPLICATIONS

Cost Factors Associated with Gas Pressure Management

Maintaining adequate gas pressure within energy storage devices involves various economic implications that stakeholders must account for. Investment in monitoring, maintenance, and technological resilience incurs costs, which must be balanced against the operational and market efficiencies gained from optimizing gas pressure.

High-performing systems capable of withstanding extreme pressures often require advanced materials and robust engineering, driving up initial costs. However, organizations may find that these upfront investments yield substantial savings long-term through improved energy efficiency and reduced operational costs. Thus, the financial landscape surrounding gas pressure management illustrates a complex interaction between costs and benefits. Understanding these economic factors informs strategic decision-making within the energy storage sector.

Market Dynamics Shaping Gas Pressure Standards

Market demands and evolving technologies continuously shape gas pressure standards within the energy storage realm. As renewable energy adoption surges, facilities are increasingly required to adapt to fluctuating supply and demand—this necessitates refined methodologies for maintaining an ideal gas pressure balance. Innovations aimed at improving energy storage efficiency are often contingent upon advancements in gas pressure technologies.

Furthermore, the competitive energy landscape persists in reshaping market dynamics, pushing organizations to seek out the most efficient and cost-effective solutions. This competitive pressure encourages research and development into new methodologies for managing gas pressure, ultimately fostering a cycle of continuous improvement. As such, the interplay between market demand and technological evolution shapes the future of gas pressure management in energy storage systems.

FUTURE TRENDS IN GAS PRESSURE MANAGEMENT

Innovations in Materials and Engineering

Emerging technologies and innovative materials continue to revolutionize the way gas pressure is managed within energy storage devices. Researchers are exploring advanced composites and synthetic materials that offer greater strength and temperature resilience while maintaining lighter weights than traditional materials. These advancements could significantly enhance the efficiency and safety of gas storage systems.

Additionally, the incorporation of smart technology in pressure monitoring systems has the potential to provide real-time analytics and predictive maintenance. This would allow operators to respond proactively to potential pressure irregularities, reducing the risk of accidents and optimizing performance. The future landscape for gas pressure management in energy storage is promising, driven by innovation and a commitment to continuous improvement.

Sustainability and Environmental Considerations

As the emphasis on sustainability grows within the energy sector, so too does the focus on the environmental impacts of gas pressure management. Solutions that reduce greenhouse gas emissions while delivering energy efficiency will be of paramount importance. Developments in carbon-neutral gas storage systems are on the horizon, promoting environmental sustainability alongside energy management.

Moreover, the pressure management strategies will increasingly incorporate renewable energy sources, contributing to a cleaner energy landscape. As stakeholders work to align their operations with global sustainability goals, innovations focusing on environmentally friendly practices will define the future trajectory of gas pressure management in energy storage. Embracing these changes is crucial for entities seeking to remain relevant and responsible within the evolving energy ecosystem.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE COMMON TYPES OF ENERGY STORAGE DEVICES?

Numerous energy storage devices exist that leverage various principles and methods to store energy. Common types include batteries, pumped hydroelectric storage, compressed air energy storage (CAES), and thermal storage systems. Batteries can range from lithium-ion to flow batteries, providing diverse options that cater to specific needs based on application. Pumped hydroelectric systems utilize gravitational potential energy, moving water between elevations to harness energy. CAES, as previously discussed, relies on compressed air at elevated pressures to store energy, providing a unique avenue for large-scale energy storage.

Furthermore, thermal storage systems capture energy in thermal form, such as molten salt systems, which are pivotal in solar power applications. Each of these systems exhibits unique advantages and inefficiencies, with selection often dictated by specific performance, environmental, and economic factors.

HOW DOES GAS PRESSURE INFLUENCE ENERGY EFFICIENCY?

Gas pressure significantly impacts the efficiency of energy storage devices, particularly those that rely on compressed gases for energy storage and retrieval. Higher gas pressure typically leads to increased energy density, allowing for greater amounts of energy to be stored within a given volume. This efficiency arises from the relationship between pressure and the energy output achieved during the release process.

Moreover, maintaining optimal gas pressure is essential for minimizing energy losses during conversion processes. Systems operating under non-ideal pressure conditions may experience energy losses due to ineffective energy conversion, which is detrimental to overall efficiency. Therefore, the accurate regulation of gas pressure is a vital factor that directly affects the performance and effectiveness of energy storage solutions.

WHAT SAFETY MEASURES SHOULD BE IMPLEMENTED FOR HIGH GAS PRESSURE SYSTEMS?

Implementing appropriate safety measures is vital for facilitating the safe operation of energy storage devices that rely on high gas pressure. Essential safety measures include regular inspections, the installation of pressure relief valves, and the use of advanced monitoring systems. These precautions serve to mitigate potential risks associated with over-pressurization or leaks that could jeopardize system integrity and public safety.

Additionally, it is paramount to ensure robust employee training protocols are in place, enabling personnel to respond effectively to any emergent situations. Adhering to industry regulations and compliance standards further fortifies the safety framework, providing an overarching policy framework that governs operational practices. Thus, fostering a proactive safety culture is critical in maintaining the security and reliability of high gas pressure systems.

In light of the multifaceted dynamics surrounding gas pressure within energy storage devices, understanding its nuances emerges as a critical factor for stakeholders aiming to optimize performance and safety. Recognizing how gas pressure varies across different technologies, the impact of temperature, relevant safety considerations, and the evolving economic implications provides a well-rounded approach to energy storage management. Furthermore, innovations in materials, engineering, and sustainability are poised to define the trajectory of energy storage solutions in the future. Effective gas pressure optimization will undoubtedly enhance efficiency while supporting the overarching transition towards sustainable energy practices. Therefore, an ongoing commitment to engage with these evolving technologies will be paramount for stakeholders seeking to thrive in the modern energy landscape.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-the-gas-pressure-of-the-energy-storage-device/