Crystalline silicon solar cells are a fascinating topic in renewable energy, characterized by their efficiency and prevalent use in solar panels worldwide. 1. These cells are composed primarily of silicon crystals, 2. they are known for their high conversion efficiency, 3. they possess a long lifespan, and 4. they have established a significant market presence. Among these points, the high conversion efficiency is particularly crucial as it determines how effectively solar energy can be transformed into usable electricity. Crystalline silicon solar cells typically convert about 15% to 22% of sunlight into electricity, which is considerably more than other types of solar technologies. This efficiency is predominantly due to the crystalline structure that allows for better light absorption and carrier mobility, amplifying the cells’ capacity to generate power. Understanding the intricate details of crystalline silicon solar cells can provide valuable insights into their role in sustainable energy production.

1. UNDERSTANDING CRYSTALLINE SILICON SOLAR CELLS

Crystalline silicon solar cells have become synonymous with solar energy technology today, capturing significant attention for their effectiveness and reliability. These devices convert sunlight into electricity by exploiting the photovoltaic effect, a process where photons excite electrons within a semiconductor material, resulting in electric current. At the heart of this process is silicon, one of the most abundant elements on Earth, making crystalline silicon an economical choice.

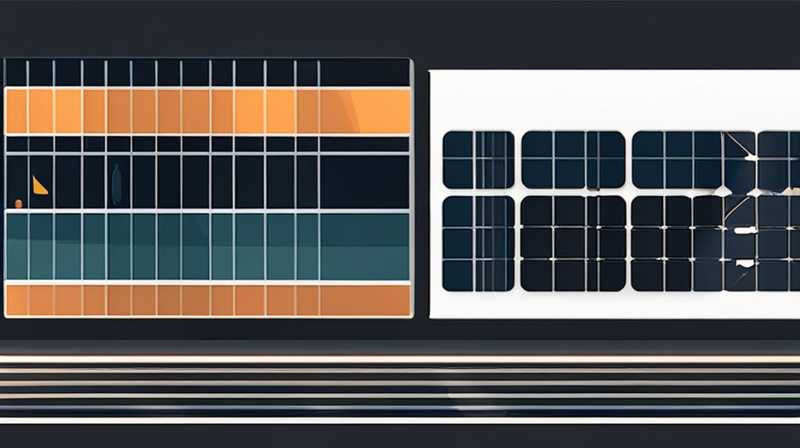

The technology primarily involves two types of crystalline silicon solar cells: monocrystalline and polycrystalline. Monocrystalline cells are made from a single continuous crystal structure, providing superior efficiency and longevity. In contrast, polycrystalline cells consist of multiple crystal structures, generally leading to a lower efficiency but at a reduced manufacturing cost. Understanding these distinctions is vital for both consumers and manufacturers, as it influences decision-making in installations and product development.

2. THE MANUFACTURING PROCESS

The production of crystalline silicon solar cells is a complex and intricate process, amounting to several essential steps. First, high-purity silicon is extracted from quartz sand, a vital raw material. This silicon undergoes processes such as reduction, purification, and crystallization. The initial phase, known as the Siemens process, involves heating silicon dioxide with carbon in an electric arc furnace to form metallurgical-grade silicon. Following this, the refinement of silicon, which contains impurities, is crucial for enhancing efficiency.

Once purified, silicon is melted and formed into either single or multi-crystal ingots. The choice between monocrystalline and polycrystalline structures is critical, as each type affects the overall performance and economic feasibility of the finished solar cells. Slicing these ingots into thin wafers constitutes the next step. The thickness of these wafers generally ranges from 156 to 200 micrometers, balancing efficiency with material use. Higher-quality silicon wafers lead to better-performing solar cells.

3. OPERATIONAL PRINCIPLES

To appreciate crystalline silicon solar cells, one must grasp their operational principles. As sunlight strikes the surface, photons transfer energy to electrons in the silicon material, resulting in the generation of free electrons and holes. This process establishes an electric field within the silicon structure, compelling electrons to move in a specific direction. The movement of these charged particles creates a flow of electricity, which can be harnessed for external use.

The efficiency of this energy conversion largely relies on several factors. Temperature, light intensity, and angle of incidence all play pivotal roles in determining output. For instance, higher temperatures typically lead to decreased efficiency due to increased resistance within the cell. Pertinently, the design and material properties of associated components, like anti-reflective coatings and conductors, also significantly influence overall efficiency.

4. ADVANTAGES OF CRYSTALLINE SILICON TECHNOLOGY

One of the most prominent advantages of crystalline silicon solar cells is their high efficiency rate, which establishes them as a leading choice in solar technology. The efficiency gains can translate into reduced land use—more power generated per square meter of installation leads to optimized spatial utilization, an essential factor in urban areas with limited space.

Longevity stands out as another critical advantage. Crystalline silicon cells typically come with warranties guaranteeing performance over 25 years, often lasting beyond that timeframe with minimal degradation. This reliability appeals not only to residential users but also to large-scale installations such as solar farms.

Economic factors come into play as well. The widespread adoption of crystalline silicon technology has resulted in dropping prices, making solar power increasingly attractive for both private and commercial investments. This cost-parity phenomenon with traditional energy sources signifies a turning point toward sustainable energy solutions.

5. MARKET PRESENCE AND TRENDS

The market for crystalline silicon solar cells continues to expand, spurred by governmental incentives and a growing awareness of climate change. As solar energy technology matures, manufacturers are consistently innovating their products, enhancing capabilities, and driving down costs. The boom in renewable energy adoption, notably in developing economies, contributes to an ever-increasing demand for affordable and efficient solar solutions.

Emerging trends also revolve around sustainability. Manufacturers are seeking to employ environmentally friendly practices throughout the production process. For instance, recycling silicon wafers and utilizing less hazardous materials in production underscores the commitment to reducing the environmental impact of solar technology.

6. INTEGRATING WITH OTHER TECHNOLOGIES

The versatility of crystalline silicon solar cells can be underscored through their potential integration with energy storage systems, smart grids, and other renewable technologies. Coupling solar cells with battery storage solutions allows for energy capture during peak sun hours and utilization during off-hours or cloudy days.

Moreover, intelligent grid systems can optimize energy distribution based on fluctuations in supply and demand. This integration facilitates a wider adoption of distributed energy systems, promoting local energy independence and efficiency. The collaborative potential of solar technology, alongside battery storage and smart systems, illustrates a crucial step towards a resilient and sustainable energy future.

7. CHALLENGES IN THE CRYSTALLINE SILICON SECTOR

Despite their numerous advantages, crystalline silicon solar cells face certain challenges worth noting. Manufacturing costs, although decreasing, still represent a considerable investment, particularly for newcomers to the market. The complexity and technological expertise required can present barriers to entry and hinder widespread adoption.

Additionally, issues surrounding resource extraction, notably in terms of sustainability, pose challenges. While silicon is abundant, the energy-intensive nature of its production raises questions regarding the long-term viability of mining practices. Adopting sustainable practices in refining and recycling becomes essential to mitigate these environmental concerns.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE DIFFERENCES BETWEEN MONOCRYSTALLINE AND POLYCRYSTALLINE SOLAR CELLS?

The core differences between monocrystalline and polycrystalline solar cells revolve around their structure and efficiency. Monocrystalline cells are crafted from a continuous single crystal structure, leading to higher efficiency rates, often between 18% to over 22%. This efficiency is attributed to their purity and uniform structure, which permits greater electron movement. Conversely, polycrystalline cells comprise multiple silicon crystals, generally resulting in slightly lower efficiency rates, typically ranging from 15% to 17%. However, due to their less intensive manufacturing processes, polycrystalline cells tend to be more cost-effective. When selecting between these two types, considerations include spatial constraints, budget, and desired energy output.

HOW LONG DO CRYSTALLINE SILICON SOLAR CELLS LAST?

Crystalline silicon solar cells are renowned for their durability and longevity. On average, these solar cells come with warranties indicating that they will maintain at least 80% of their original output for 25 years. In practice, many monocrystalline cells can continue to operate above this threshold for up to 30 years or more. Factors influencing their lifespan include the quality of materials used, installation techniques, and ongoing maintenance. Regular cleaning and inspections can help identify potential issues early and maximize efficiency. Thus, investing in high-quality crystalline silicon panels can lead to long-term performance and significant energy yield over their operational life.

WHAT IMPACT DO WEATHER CONDITIONS HAVE ON THE PERFORMANCE OF SOLAR CELLS?

Weather conditions play a crucial role in the performance of crystalline silicon solar cells. Sunny days maximize energy capture, while cloudy weather can markedly reduce solar generation; however, clouds do not eliminate energy production entirely, as diffused sunlight can still reach solar panels. Temperature is another critical factor; while lower temperatures can enhance efficiency, exceptionally high temperatures can lead to diminished performance. Additionally, environmental conditions like snow, dust, and rain can impact energy generation. Snow can act as an insulator, temporarily blocking sunlight, while dust accumulation can reduce light absorption. Regular maintenance and cleaning can help mitigate these effects, ensuring optimal performance across various weather scenarios.

Summarizing all provided insights into the relevance and implications of crystalline silicon solar cell technology underscores its pivotal role in shaping the future of energy. These solar cells, with their high conversion efficiency and long lifespan, represent a potent solution to the pressing energy needs of today and contribute significantly toward achieving sustainability goals. Addressing challenges such as production costs and environmental impacts through innovation will further enhance their application across a spectrum of uses. The integration with additional technologies signifies an evolution towards a more sustainable energy framework. With ongoing advancements in manufacturing, efficiency, and integration, crystalline silicon solar cells are positioned to remain at the forefront of the renewable energy landscape. By embracing these developments and addressing challenges, the transition to renewable energy sources can be accelerated, thereby fostering a cleaner, greener future for generations to come.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-the-film-of-crystalline-silicon-solar-cell/