What is Solar Circuit Board Assembly

In the realm of renewable energy, solar circuit board assembly is the process of integrating various components onto a printed circuit board (PCB) intended to manage and optimize solar energy systems. 1. This assembly is crucial for the functioning of solar panels and inverter systems, ensuring that electrical connections are reliable and efficient. 2. Specialized techniques and materials are often utilized to enhance durability and performance, considering environmental factors like humidity and temperature fluctuations. 3. Quality assurance during the assembly process is paramount to achieve longevity and reliability in operation. The significance of efficient assembly cannot be overstated, as it affects overall energy conversion efficiency.

1. UNDERSTANDING SOLAR CIRCUIT BOARD ASSEMBLY

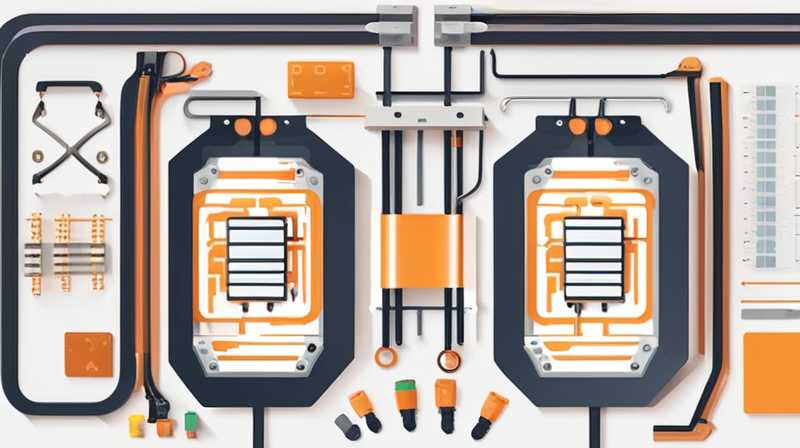

Solar circuit board assembly refers to a specialized method involving the configuration of electronic components essential for the operation of solar energy systems. This process entails mounting various elements, such as resistors, capacitors, and microcontrollers, onto printed circuit boards. These boards act as the backbone of solar technologies, providing structured pathways for electrical signals. As solar technology evolves, the complexity of these assemblies increases, demanding higher precision and advanced manufacturing techniques. Reliability and efficiency in these assemblies become pivotal to achieving optimal performance in solar energy systems.

Delving deeper into the role of solar circuit boards illustrates their function in interfacing multiple components. Solar inverters, for instance, require an intricate array of circuits to convert direct current (DC) from solar panels into alternating current (AC), which is usable by household appliances. This conversion process necessitates the smooth operation of printed circuit boards to minimize energy loss and ensure that energy can be fed back into the grid safely. Thus, an understanding of the intricacies of solar circuit board assembly reveals why attention to detail during assembly processes can significantly impact overall solar energy system performance.

2. COMPONENTS USED IN SOLAR CIRCUIT BOARD ASSEMBLY

The components incorporated into solar circuit board assemblies are fundamental to their functionality. Each part plays a different role, contributing to the optimization and efficiency of solar energy systems. Key components include semiconductors, passive components, and connectors.

Semiconductors, such as silicon chips, dominate the landscape due to their efficiency in managing electrical signals. In solar inverters, these chips are essential for regulating voltage levels and ensuring safe energy conversion. Meanwhile, passive components like capacitors and inductors help smooth electrical fluctuations, safeguarding sensitive components from potential surges. Additionally, connectors play a vital role in establishing reliable links between different parts. Understanding the specific requirements of each component adds layers of complexity to the assembly process, highlighting the necessity for expertly crafted designs.

Moreover, the choice of materials is crucial in determining the longevity and reliability of the assembly. High-temperature resistant materials are often utilized to withstand the varied environmental conditions that solar technology faces. Furthermore, such materials contribute to minimizing issues related to corrosion and degradation, ensuring the sustainability of the assemblies over time. Thorough knowledge of these components, along with their application and interaction within a solar circuit board, is paramount to achieving a well-functioning assembly capable of delivering consistent performance.

3. MANUFACTURING PROCESSES IN SOLAR CIRCUIT BOARD ASSEMBLY

The production of solar circuit boards encompasses various techniques aimed at achieving precision and reliability. From the initial design phase to the final inspection, each step necessitates meticulous attention to detail and adherence to stringent quality standards. One predominant method employed is surface mount technology (SMT), enabling efficient assembly of components on both sides of the PCB, which ultimately saves space and enhances performance density.

SMT facilitates quick placement of components, ensuring that production lines can operate at speeds conducive to meeting high market demands. Conversely, through-hole technology is also utilized, primarily for larger components that require robust connections. The combination of both methods illustrates the adaptability of manufacturers to address different design requirements effectively, thereby optimizing the assembly output.

Following the assembly, a critical phase is the quality assurance process. This stage incorporates a series of tests designed to detect potential defects and ensure compliance with industry standards. Thermal cycling tests, solder ability inspections, and electrical integrity checks are paramount in this phase. Through these rigorous evaluations, manufacturers can ascertain the longevity and operational reliability of the solar circuit boards. Establishing a comprehensive quality inspection protocol enhances consumer confidence, ensuring that the assembled products meet performance expectations under various environmental conditions.

4. CHALLENGES IN SOLAR CIRCUIT BOARD ASSEMBLY

Despite advancements in technologies and methodologies, various challenges persist in the arena of solar circuit board assembly. One prominent obstacle arises from the demand for faster production cycles; manufacturers often grapple with balancing speed and accuracy. Achieving quick turnaround times can lead to compromises in quality, potentially affecting the performance of the solar systems in the long run.

Environmental factors also pose unique challenges in assembly processes. The components must withstand diverse climatic conditions, ranging from extreme heat to moisture. Manufacturers face the pressure of designing circuit boards that not only operate efficiently but are also resilient against these environmental stressors. This necessitates ongoing research and development to identify new materials and coatings that enhance durability.

Furthermore, the ongoing evolution of technology means that solar circuit board designs are perpetually changing. As innovations emerge, manufacturers must adapt swiftly to incorporate new components and comply with updated standards and regulations. This need for constant adaptation can strain existing processes and may even require investment in new machinery or training for workforce members. The fusion of these diverse challenges underlines the complexity of solar circuit board assembly.

FAQs

WHAT ARE THE MAIN BENEFITS OF USING SOLAR CIRCUIT BOARDS IN SOLAR ENERGY SYSTEMS?

Solar circuit boards, designed for solar energy systems, offer numerous advantages that significantly contribute to increasing efficiency and performance. One of the primary benefits is their role in optimizing energy conversion processes. By effectively managing electrical signals, they enhance the conversion of direct current (DC) from solar panels into usable alternating current (AC). This maximizes energy output and ensures that solar systems operate efficiently. Additionally, implementing advanced technologies within the circuit boards can further enhance power management functions, supporting smart-grid compatibility.

Moreover, the durability of solar circuit boards is paramount to their effectiveness. Many designs incorporate materials resistant to harsh environmental conditions, such as extreme temperatures and moisture, which prolong their operational lifespan. Ensuring reliability not only decreases maintenance requirements but also translates into long-term cost savings for operators. In conjunction with these advancements, ongoing research continuously leads to enhancements in performance and reliability, allowing solar circuit boards to adapt as technology evolves. Consequently, their integration into solar energy solutions fosters both economic viability and sustainability in the realm of renewable energy.

WHAT ARE THE KEY COMPONENTS OF A SOLAR CIRCUIT BOARD?

The design of a solar circuit board comprises various integral components, each playing a specialized role in ensuring functional performance. Key elements include semiconductors, passive components, and connectors. Semiconductors serve as the heartbeat of the assembly, regulating electrical signals and voltage levels. Common examples include silicon chips, crucial for efficient energy conversion in solar inverters.

Passive components, such as capacitors and inductors, are pivotal for stabilizing the circuits, reducing fluctuations in electrical current, and protecting sensitive devices from potential surges. Additionally, connectors facilitate reliable electrical interconnections between various components, ensuring seamless system operation. Each of these parts is carefully selected based on specific operational parameters, ultimately creating a cohesive assembly capable of maximizing energy efficiency.

Fundamentally, the performance and reliability of solar circuit boards hinge on the proper integration of these components. Understanding the importance of their roles allows manufacturers and engineers alike to design assemblies that operate effectively in diverse settings. By leveraging advancements in materials and technologies, circuit board compositions are continuously evolving to enhance performance in renewable energy applications.

HOW DOES QUALITY ASSURANCE IMPACT SOLAR CIRCUIT BOARD ASSEMBLY?

Implementing quality assurance practices in solar circuit board assembly influences both performance and long-term viability significantly. During the manufacturing process, ensuring that every component is precisely integrated is essential to prevent the risk of failure or decreased efficiency. Quality assurance encompasses a series of inspections and tests designed to identify defects and confirm compliance with industry standards.

Testing methods such as thermal cycling assessments and solder integrity evaluations help ascertain whether circuit boards can withstand various environmental stressors. By ensuring quality at each step, from initial component selection to final assembly inspection, manufacturers position themselves to deliver reliable products that meet market demands. Not only does this foster consumer trust, but it also reduces the costs associated with warranty claims and repairs—benefits that directly enhance a company’s reputation in a competitive environment.

Furthermore, rigorous quality assurance also aligns with regulatory compliance. As global standards are set for renewable energy technologies, incorporating these practices ensures that companies remain compliant while contributing positively to the industry’s growth. By prioritizing quality assurance, manufacturers ultimately create a sustainable model that prioritizes performance, reliability, and consumer trust.

Solar circuit board assembly represents a critical component in the success of solar energy applications. Emphasizing accuracy in assembling these boards enhances performance across the board, while also contributing to sustainability. By understanding the challenges, components, and quality assurance processes involved, stakeholders can foster innovations that propel the field forward. The continued advancement in assembly technologies and materials enables more efficient energy solutions, underscoring the dynamic and essential nature of this discipline within the renewable energy industry.

Investing in the expertise and precision required for solar circuit board assembly not only optimizes the lifespan of renewable energy solutions but also bolsters the entire ecosystem surrounding clean energy technologies. As the world progressively shifts towards sustainable energy sources, refining assembly processes will play an essential role in meeting energy demands while promoting environmentally friendly practices. Therefore, ongoing education and innovation will signify future expansions within this pivotal industry. The correlation between well-executed assemblies and the efficiency of solar technologies remains an undeniable advantage in the quest for a greener, more sustainable energy future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-solar-circuit-board-assembly/