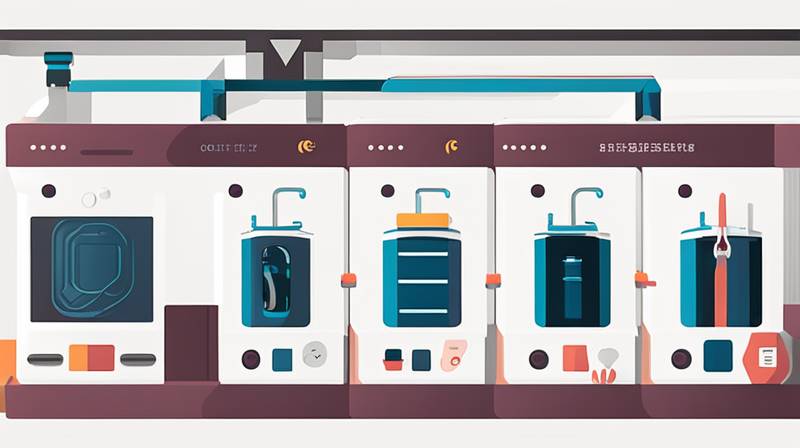

Energy storage welding machines are advanced devices that utilize innovative technology to provide efficient, precise, and controlled welding processes. 1. These machines store energy for short durations, enabling them to release it quickly when needed, 2. They enhance productivity by reducing welding time significantly, 3. They ensure a stable energy supply, which leads to high-quality welds, 4. These units are versatile and can be used in various applications from automotive to construction industries.

One of the core advantages of energy storage welding machines is their capability to maintain a consistent energy output. This is achieved through the use of capacitors and other energy storage devices that can deliver power in rapid bursts. The efficiency of time and energy usage not only optimizes operational costs but also improves the overall quality and durability of the welds produced. Such precision and adaptability make them increasingly popular among professionals looking for reliable welding solutions.

1. UNDERSTANDING ENERGY STORAGE WELDING MACHINES

The evolution of welding technologies has led to the advent of energy storage welding machines, which represent a paradigm shift in the welding landscape. Traditional welding methods have relied on steady power supplies, often resulting in inefficiencies and suboptimal weld quality. In contrast, an energy storage welding machine captures energy during idle periods and deploys it in concentrated bursts when welding is required. This innovation facilitates a high degree of control over the welding process.

Moreover, the underlying mechanism involves capacitive storage, which allows for instantaneous energy delivery. This is crucial, as welding, fundamentally, requires significant bursts of energy to melt and fuse materials. The ability to swiftly transfer energy ensures that the heat generated does not dissipate too quickly, thus achieving deeper penetration and stronger welds. Consequently, operators benefit not only from enhanced weld quality but also from increased throughput during production cycles.

2. ADVANTAGES OF ENERGY STORAGE WELDING MACHINES

Several factors underscore the superiority of energy storage welding machines compared to traditional models. Firstly, the efficiency of energy use is remarkably high. By storing energy when it is not needed, these machines minimize wastage and ensure that energy is only consumed during the actual welding phase. This leads to lower operational costs over time, making it economically advantageous for businesses looking to optimize expenses.

Secondly, the versatility of these machines is a significant benefit. They are compatible with various welding processes, including MIG, TIG, and stick welding. This adaptability allows operators to switch between techniques without requiring extensive reconfiguration. Moreover, energy storage welding machines often come equipped with advanced features such as digital control systems, showcasing their ability to cater to different material types, thicknesses, and joint configurations effectively.

3. APPLICATIONS IN INDUSTRIES

Energy storage welding machines have found numerous applications across various industries, thanks to their effectiveness and efficiency. In the automotive industry, they are increasingly used for assembling components where precision is paramount. The capability to produce clean, consistent welds reduces the likelihood of defects, which is critical in manufacturing processes that prioritize quality and safety.

In construction, these machines play a vital role in reinforcing structures. Their ability to deliver high energy levels ensures solid joints in metal frameworks, thereby enhancing the safety and durability of buildings and other structures. Furthermore, the rapid energy discharge capabilities allow for quicker assembly processes, leading to shorter project timelines and improved profitability.

4. TECHNOLOGICAL INNOVATIONS

The technological advancements incorporated in energy storage welding machines cannot be overlooked. The integration of smart technology has transformed these machines into sophisticated tools capable of self-monitoring and real-time adjustments during welding operations. This is achieved through the utilization of digital sensors that continuously assess the welding environment and make necessary modifications to maintain ideal welding conditions.

Additionally, modern energy storage welding machines often feature user-friendly interfaces, enabling operators—regardless of experience level—to navigate controls effortlessly. This not only enhances productivity but also minimizes the risk of errors during operation. As the industry adopts more complex materials and applications, the continuous evolution of these machines will likely include even more innovative features aimed at further optimizing the welding process.

FREQUENTLY ASKED QUESTIONS

WHAT IS THE DIFFERENCE BETWEEN ENERGY STORAGE WELDING MACHINES AND TRADITIONAL WELDING MACHINES?

The primary distinction between energy storage welding machines and traditional models lies in their energy delivery systems. Traditional welding machines maintain a constant energy output which can lead to inefficiencies and a longer operational time for projects. In contrast, energy storage welding machines have the ability to store energy for short durations, releasing it in bursts during the welding phase. This leads to not only reduced energy consumption but also improves productivity through quicker welding processes. These machines are also designed to provide more precise control, which translates into higher quality welds with reduced defects. As a result, businesses can achieve significant cost savings and enhanced quality in their welded products.

CAN ENERGY STORAGE WELDING MACHINES BE USED ON DIFFERENT MATERIALS?

Yes, energy storage welding machines exhibit remarkable versatility, allowing them to be employed across a variety of materials including steel, aluminum, and even exotic alloys. Their ability to make rapid energy adjustments enables them to adapt to the specific welding requirements of different materials effectively. Operators can modify the energy input depending on the thickness and type of material being welded, ensuring optimal weld penetration and integrity. Moreover, the machines’ advanced technological features often include customizable settings, allowing them to efficiently handle a wide range of applications—from automotive manufacturing to intricate repair jobs in aerospace. This adaptability makes them an attractive option for industries looking to streamline their welding processes across multiple material types.

WHAT MAINTENANCE IS REQUIRED FOR ENERGY STORAGE WELDING MACHINES?

Maintaining energy storage welding machines is crucial to ensure their longevity and efficiency. Regular inspections are necessary to check for wear and tear on components like capacitors and digital control systems. Cleaning the electrical contacts and ensuring that power connections are secure can prevent potential overheating and electrical failures. Additionally, operators should frequently test the calibration of the machine to ensure weld quality remains consistent over time. Proper storage conditions are also important; they should be kept in a dry environment to prevent damage from moisture or corrosive elements. Conducting routine maintenance checks and adhering to manufacturer guidelines can significantly enhance performance and safety, yielding an optimal return on investment over the lifecycle of the equipment.

Energy storage welding machines signify a transformative approach to welding, heralding a new era of efficiency and precision. These devices leverage advanced technology to accumulate energy and deliver it in rapid bursts tailored to the specific requirements of the welding task. By optimizing energy utilization, they not only reduce operational costs but also enhance the quality of the welds produced. Industries ranging from automotive to construction have seamlessly integrated these machines, excelling in applications that necessitate accuracy and durability. As technological innovations continue to emerge, the capabilities of energy storage welding machines are expected to expand, further broadening their applicability and enhancing their functional versatility. The operational ease and adaptability of these systems present a compelling argument for their adoption across diverse sectors, promising significant enhancements in productivity and quality control. Ultimately, the preeminence of energy storage welding machines underscores a shift towards smarter, more efficient manufacturing practices that are essential in today’s competitive market landscape. Embracing this technology not only positions businesses at the forefront of innovation but also secures their standing in an ever-evolving industry.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-energy-storage-welding-machine/