An injection molding accumulator is a device utilized in the injection molding process to store and release hydraulic energy efficiently, enhancing the precision and performance of the injection molding machine. 1. It serves to maintain consistent pressure throughout the injection phase, ensuring high-quality production results. 2. Its ability to rapidly provide hydraulic fluid minimizes cycle times, thus improving production efficiency. 3. An accumulator can also stabilize the hydraulic system, which is crucial for controlled injection, helping to prevent fluctuations in pressure that could lead to defects. 4. Overall, accumulators optimize the energy consumption in the context of injection molding, translating into cost savings and more sustainable manufacturing practices.

UNDERSTANDING INJECTION MOLDING ACCUMULATORS

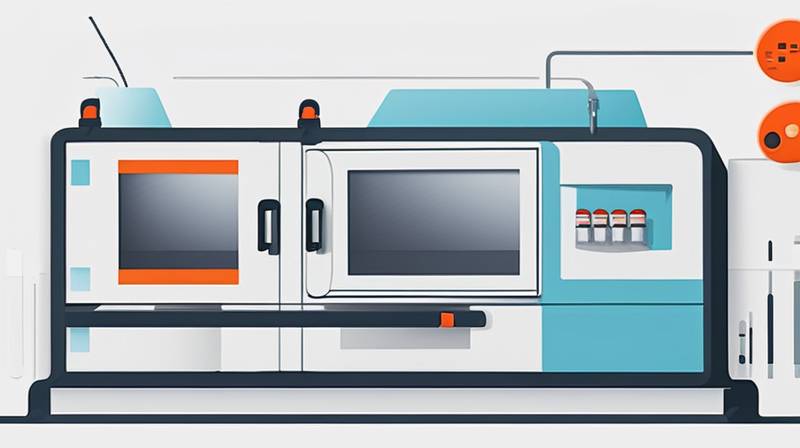

Injection molding is a sophisticated manufacturing process that constructs parts by injecting molten material into a mold. The functionality of an injection molding machine relies heavily on hydraulic systems, which manage the movement of the injection unit. An injection molding accumulator plays a pivotal role in this hydraulic system, acting as an auxiliary component designed to enhance various operational aspects. By storing hydraulic energy for repeated use, this device contributes significantly to the efficiency and productivity of injection molding operations. The accumulator provides a reservoir of hydraulic fluid that can be harnessed instantly, facilitating smoother transitions within the injection process.

The design of the accumulator may vary, but it generally consists of a chamber separated by a flexible membrane or piston. This configuration enables the storage of pressurized hydraulic fluid, creating a buffer that compensates for fluctuations in demand during the injection cycle. Such a mechanism is crucial when considering the rapid succession of injection cycles that modern manufacturing facilities often utilize. The accumulator allows for the quick release of stored fluid, ensuring that the molding machine can respond promptly to the injection requirements, hence reducing cycle times and maintaining consistent quality in the finished products.

MECHANICS OF OPERATION

To fully appreciate the capabilities of an injection molding accumulator, it is important to delve into the mechanics of its operation. The fundamental principle behind the accumulator’s functionality is based on the storage and release of pressurized hydraulic fluid. During operation, the accumulator fills with hydraulic fluid to a predetermined pressure. The pressure within the accumulator is typically set higher than that of the hydraulic system to ensure that fluid can be quickly released when necessary.

When the injection phase begins, the accumulator releases its stored hydraulic fluid into the injection cylinder, providing an immediate boost in pressure and volume. This additional hydraulic power effectively supplements the existing supply from the hydraulic pump, allowing for a more rapid and forceful injection of the molten material into the mold cavity. The result is a quicker cycle time, as the machine can maintain ideal pressure levels without excessive reliance on the hydraulic pump alone.

As the hydraulic fluid is directed back into the accumulator, it does not merely wait for the next injection cycle. Instead, it aids in stabilizing the entire system, ensuring that pressure fluctuations are minimized. Such stabilization is particularly important in high-speed, high-volume injection molding setups, where even minor variations in pressure can lead to significant defects in the final product.

ADVANTAGES OF USING ACCUMULATORS

The incorporation of injection molding accumulators brings numerous advantages to the manufacturing process. First and foremost, these devices enhance the overall productivity of injection molding machines. By minimizing the time needed to achieve desired pressure levels during the injection cycle, businesses can significantly increase their output without compromising quality.

Beyond productivity, the energy efficiency of the manufacturing process is substantially improved through the use of accumulators. Accumulators store hydraulic energy during non-peak operating moments, which can then be efficiently released during high-demand phases, thereby reducing the load on hydraulic pumps. Consequently, this decrease in demand helps lower energy consumption, ultimately contributing to lower operational costs.

Moreover, the consistent delivery of hydraulic pressure facilitated by accumulators ensures uniformity in the injected material, translating to a decreased incidence of defects such as inconsistent wall thickness and incomplete molds. This uniformity is essential for manufacturers looking to produce high-quality, reliable products that meet stringent industry standards. By incorporating an accumulator into the injection molding process, manufacturers can consistently produce parts that adhere to specified tolerances with better surface finishes.

COMMON APPLICATIONS OF INJECTION MOLDING ACCUMULATORS

Injection molding accumulators are employed across various industries, each benefiting from the device’s efficiency and reliability. The automotive sector is one of the leading users, with accumulators playing a critical role in producing components such as dashboards, bumpers, and interior parts. The need for precision and consistency in automotive manufacturing makes the use of accumulators nearly indispensable.

In addition to the automotive industry, the consumer goods sector also harnesses the capabilities of injection molding accumulators. Products ranging from household items to electronic equipment often require high-volume production with exceptional accuracy, making accumulators a valuable asset. Features like durability and detail-oriented designs can be consistently achieved thanks to the reliable hydraulic pressure provided by these devices.

Furthermore, the packaging industry extensively utilizes injection molding techniques to create various containers, caps, and closures. In such applications, time sensitivity and precise dimensions are crucial, hence the adoption of accumulators aids in achieving rapid production cycles while maintaining product integrity. The unique requirements of different sectors showcase the versatility of injection molding accumulators.

MAINTENANCE AND OPERATIONS

Effective maintenance of injection molding accumulators is vital to ensure peak performance and longevity. Regular inspection of the hydraulic fluid levels is essential, as the accumulator’s efficiency hinges on the availability of properly maintained hydraulic fluid. Contaminated or low-quality hydraulic fluid can lead to malfunctions and decreased efficiency over time.

Moreover, examining the seals and membranes within the accumulator for wear and tear is critical. Any leaks or damages can undermine the accumulator’s efficiency by allowing pressurized fluid to escape, reducing the device’s ability to function effectively. Scheduled maintenance routines can include checking the pressure settings in the accumulator to ensure they align with industry best practices, as improper settings can lead to performance issues or system failure.

Operators of injection molding machines must also be knowledgeable about recognizing the signs of an underperforming accumulator. Indicators such as fluctuating injection pressures, increased cycle times, or inconsistent product quality can point to accumulator-related issues. By proactively addressing potential problems, manufacturers can spare themselves from costly downtimes, thus enhancing the overall productivity of the injection molding process.

FUTURE TRENDS IN ACCUMULATOR TECHNOLOGY

As technology continues to evolve, so too does the design and functionality of injection molding accumulators. One emerging trend is the integration of smart technology to enhance operational monitoring and maintenance capabilities. By equipping accumulators with sensors, manufacturers can gather real-time data related to pressure levels, fluid quality, and performance metrics. This data can then be analyzed, allowing for more informed decision-making regarding maintenance schedules and operational adjustments.

Another promising trend is the development of advanced materials for accumulator construction. Lightweight and highly durable materials can be utilized to improve the flexibility and responsiveness of the accumulator, facilitating performance in high-pressure environments. As production demands increase, the need for components that can withstand challenging operational conditions becomes more pronounced.

Sustainability is also a core focus moving forward. Manufacturers are exploring hydraulic fluids that are more environmentally friendly, ensuring compliance with regulations and reducing the ecological impact of injection molding processes. These trends signal a shift towards not only enhancing efficiency and productivity but also aligning manufacturing processes with current global sustainability objectives.

FREQUENTLY ASKED QUESTIONS

WHAT IS THE ROLE OF AN INJECTION MOLDING ACCUMULATOR IN A MANUFACTURING SETUP?

An injection molding accumulator plays a critical role in the hydraulic system of an injection molding machine. It serves to store hydraulic fluid at elevated pressures, which can be released rapidly during the injection phase. This capability not only enhances the efficiency of the injection process but also ensures that the required pressure levels are maintained consistently. By allowing for quick fluid release, the accumulator minimizes cycle times and stabilizes hydraulic pressure, resulting in a smoother operation. Additionally, an accumulator can contribute to energy savings by reducing the load on hydraulic pumps, optimizing overall energy consumption within the manufacturing setup.

HOW DOES THE USE OF ACCUMULATORS IMPACT PRODUCTION EFFICIENCY?

The incorporation of accumulators into an injection molding operation enhances production efficiency significantly. By storing hydraulic energy, these devices allow for quick and responsive fluid release, which reduces the time needed for each injection cycle. This rapid response capability ensures that the injection machine can maintain optimal pressure levels, leading to more consistent and high-quality output. In environments with high demand for production, the usage of accumulators can lead directly to increased throughput and lower operational costs. The accumulated hydraulic energy also stabilizes the system, decreasing the likelihood of defects during the injection process, thus promoting a higher yield of acceptable products.

WHAT MAINTENANCE PRACTICES SHOULD BE FOLLOWED FOR INJECTION MOLDING ACCUMULATORS?

Regular maintenance of injection molding accumulators is essential to ensure their optimal performance and longevity. Key practices include inspecting hydraulic fluid levels, examining seals and membranes for wear, and ensuring that pressure settings are properly calibrated. It is also advisable to conduct periodic checks for leaks or any irregularities in performance, as these can signal the need for immediate repair. Operators should be trained to recognize the signs of a failing accumulator, such as fluctuations in pressure or inconsistent cycle times. Implementing a routine maintenance schedule can greatly reduce the risk of malfunctions and help sustain efficient production processes.

The discussion surrounding injection molding accumulators highlights their indispensable role within contemporary manufacturing environments. The storage and rapid release of hydraulic energy ensure that injection molding machinery operates at peak efficiency, thus driving overall productivity and quality. Not only do these devices optimize cycle times, but they also contribute significantly to the sustainability efforts of manufacturers by decreasing energy consumption. Therefore, understanding the intricacies of injection molding accumulators is essential for organizations aiming to harness the full potential of their injection molding operations. With emerging trends pointing towards smart technology and the usage of advanced materials, the future of injection molding accumulators promises breakthroughs that will further enhance their efficacy. By implementing robust maintenance practices and keeping abreast of industry innovations, manufacturers can maximize the advantages offered by accumulators, thus cementing their position in a competitive market. The ongoing evolution of manufacturing technology will undoubtedly continue to place a spotlight on the functionality of injection molding accumulators, ensuring they remain a core component of efficient production systems.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-an-injection-molding-accumulator/