What is a phase change energy storage heat exchanger: A phase change energy storage heat exchanger is an innovative technology that utilizes phase change materials (PCMs) to efficiently store and transfer thermal energy. 1. This system enables improved thermal management in various applications, 2. enhances energy efficiency by storing excess thermal energy, 3. facilitates the use of renewable energy sources, 4. helps in reducing carbon emissions. Phase change materials operate by absorbing or releasing significant amounts of heat when they transition between solid and liquid phases. This capability allows for the moderation of temperature fluctuations and the storage of energy for later use, offering substantial benefits in industrial, commercial, and residential settings.

1. UNDERSTANDING PHASE CHANGE MATERIALS

Phase change materials are substances that absorb or release thermal energy during their phase transition, particularly between solid and liquid states. These materials have a unique ability to store energy when they melt and release it when they solidify, making them pivotal in energy management applications. The temperature at which this phase change occurs is known as the melting point, and it is a critical factor in determining the practicality of a PCM for specific applications. When designing a heat exchanger that utilizes PCMs, careful selection is essential, as the desired thermal characteristics must align with the operational environment.

In applications where thermal regulation is crucial, phase change materials release their stored energy in a controlled manner, maintaining a constant temperature in the surrounding environment. This characteristic is ideal for numerous applications including building heating and cooling systems, solar energy storage, and industrial processes that require consistent temperature control. The energy storage capability can significantly reduce peak energy consumption, leading to cost savings and enhanced efficiency in energy use.

Moreover, PCMs come in various categories, such as organic, inorganic, and eutectic options, each presenting unique properties suited for different thermal management needs. Organic PCMs, for example, offer higher stability and non-corrosive characteristics but typically have lower thermal conductivity, which may necessitate supplementary materials to enhance performance. Inorganic PCMs often have higher energy densities, but they can be prone to issues such as supercooling or sedimentation during repeated cycle use.

2. FUNCTIONALITY OF PHASE CHANGE ENERGY STORAGE HEAT EXCHANGERS

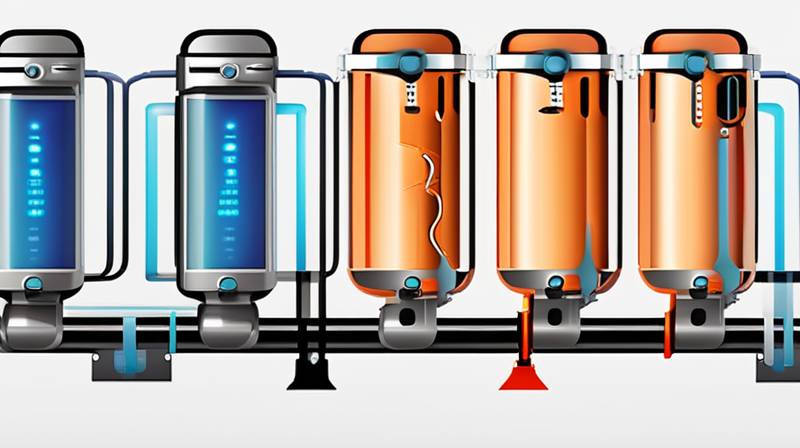

A phase change energy storage heat exchanger operates by integrating PCMs within heat exchange systems to maximize their thermal energy transfer efficiency. The core functionality revolves around capturing excess thermal energy generated from various processes and storing that energy until it is required. This allows the system to manage thermal loads efficiently, thus ensuring that energy is used effectively rather than dissipated as waste heat.

The design typically incorporates a series of pipes or storage containers filled with a PCM. As the temperature of the system rises, the PCM absorbs heat, transitioning from a solid to a liquid state. This phase change absorbs and retains thermal energy, which can then be utilized when the operational temperature decreases, allowing the material to solidify and release the stored heat. By optimizing this cycle, phase change storage systems can effectively smooth out temperature peaks and troughs.

Furthermore, the incorporation of advanced materials and nanotechnology can enhance the performance of these systems. For instance, using nanomaterials can significantly increase the thermal conductivity of PCMs, enabling quicker absorption and release of thermal energy. These advancements are essential for achieving optimal performance, specifically in high-demand applications, ensuring that the phase change materials can respond rapidly to changes in energy needs.

3. APPLICATIONS AND BENEFITS

The potential applications of phase change energy storage heat exchangers are extensive, covering sectors such as industrial manufacturing, residential heating and cooling, and renewable energy integration. In industrial contexts, these systems are invaluable in managing process heat loads, allowing factories to offset energy consumption during peak hours. For instance, during operations that generate substantial waste heat, PCS systems can store this energy for later use in heating or even to drive absorption chillers, promoting eco-friendly practices.

In residential applications, implementing PCMs within building materials can contribute to significant energy savings. Homeowners can benefit from more consistent indoor temperatures without excessive reliance on heating and cooling systems. This leads to lower energy bills, an important consideration for many households striving to reduce living costs. Additionally, the reduced strain on HVAC systems can extend their lifespan, further enhancing cost-effectiveness over time.

Moreover, as renewable energy sources like solar and wind energy are intermittent, phase change energy storage heat exchangers facilitate energy storage and optimal utilization. By storing excess energy generated during peak production times, these systems enable a steadier energy supply when production dips, stabilizing energy flows in electrical grids and enhancing the viability of renewable energy sources. Not only do these systems provide energy savings, but the reductions in demand peaks can lower the carbon footprint associated with energy production, promoting sustainability across various sectors.

4. CHALLENGES AND LIMITATIONS

While the benefits of phase change energy storage heat exchangers are notable, there exist certain challenges and limitations that must be addressed. The initial costs for implementation and material selection can be significant, presenting a barrier, particularly for smaller enterprises or residential applications. When considering the lifecycle and long-term operating costs, however, many organizations find that the investment can lead to substantial savings due to improved efficiency and reduced energy costs.

Another challenge lies in the selection and integration of appropriate PCMs for different applications. As previously mentioned, variations in thermal conductivity, phase change temperatures, and stability must be carefully considered to ensure the system operates efficiently. There is a risk of underperformance if the selected PCM does not align perfectly with the operating conditions, which could lead to wasted energy or inadequate thermal management.

Additionally, ongoing research and development efforts are necessary to enhance the thermal properties and performance consistency of phase change materials used in these systems. As innovations in technology emerge, the hope is to overcome existing material limitations and optimize the overall effectiveness of phase change energy storage heat exchangers.

FAQs

WHAT ARE THE COMMON PHASE CHANGE MATERIALS USED IN HEAT EXCHANGERS?

Various phase change materials have been identified for use in heat exchangers, with organic, inorganic, and eutectic materials being the most prevalent. Organic phase change materials include paraffins and fatty acids, which offer thermal stability and a wide range of melting temperatures. These materials are favored for their low toxicity and ease of handling, making them suitable for residential applications.

Inorganic phase change materials, such as salt hydrates, exhibit high energy density but may face challenges with supercooling and potential corrosion. Many advanced applications leverage salt hydrates for their thermal properties but require additional measures to mitigate these challenges. Eutectic mixtures blend different compounds to achieve a specific melting point and can often be tailored for niche applications requiring precise temperature regulation.

While the choice of PCM greatly influences the performance of the energy storage heat exchanger, advances in nanomaterials also present new opportunities for enhancing traditional PCMs. Through research and development, the effectiveness of these materials can be improved, making them better suited for modern applications.

HOW DO PHASE CHANGE ENERGY STORAGE HEAT EXCHANGERS IMPROVE ENERGY EFFICIENCY?

Phase change energy storage heat exchangers contribute to energy efficiency by allowing systems to manage thermal loads effectively, reducing reliance on traditional energy sources during peak demand periods. By storing excess energy generated during off-peak periods, such as nighttime for solar systems or when industrial operations generate excess heat, these systems can release stored energy during peak demand, which lowers energy costs.

Moreover, these systems help stabilize temperatures within buildings or industrial processes. By minimizing temperature fluctuations, they decrease the need for additional heating or cooling, leading to energy savings. As a result, energy consumption during peak hours is reduced, contributing to a more efficient energy grid and potentially lowering overall energy prices.

Additionally, phase change energy storage heat exchangers can support the integration of renewable energy, enabling unused energy to be stored for later use. This not only enhances the efficiency of renewable systems but also encourages a shift toward more sustainable energy practices, reducing the overall carbon footprint associated with energy consumption.

WHAT ARE THE KEY FACTORS TO CONSIDER WHEN DESIGNING A PHASE CHANGE ENERGY STORAGE HEAT EXCHANGER?

When designing a phase change energy storage heat exchanger, several key factors must be considered to ensure optimal performance. The selection of appropriate phase change materials is paramount, as it influences the thermal performance and stability of the system. The melting point of the PCM should align closely with the operating temperatures of the system to maximize energy absorption and release capabilities.

Thermal conductivity also plays a crucial role. Higher thermal conductivity materials allow for more rapid energy transfer, ensuring that the PCM can absorb or release heat quickly when required. This responsiveness is essential in applications with fluctuating thermal loads.

System integration and design are also critical. The layout of the heat exchanger, including flow directions and surface areas for heat transfer, must be optimized to promote efficient energy exchange. Additionally, consideration should be given to insulation and minimizes thermal loss, as any delays in energy transfer can significantly impact overall efficiency.

Lastly, factors such as durability and lifecycle costs should be evaluated. Choosing materials that withstand the operational environment will improve longevity and reduce maintenance costs, leading to a more reliable and efficient heat exchanger system in the long run.

The adoption of phase change energy storage heat exchangers marks a significant advancement in thermal energy management.

Through the utilization of innovative phase change materials, these systems offer enhanced energy efficiency, provide solutions for temperature regulation, and facilitate the integration of renewable energy sources. As industries and residential applications strive for greater sustainability and better thermal management, these technologies emerge as invaluable tools to meet evolving energy needs. The continued research and development within this field promise to address existing challenges, enhancing the capabilities of phase change energy storage systems while paving the way for broader adoption and improved performance in various sectors. Innovations may lead to novel materials and integration strategies. Ultimately, as society grapples with the challenges of energy consumption and climate change, phase change energy storage heat exchangers represent a pivotal step forward in achieving a sustainable energy future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-a-phase-change-energy-storage-heat-exchanger/