A coal storage bunker is a robust structure designed to securely hold and preserve coal used for various energy and industrial purposes. 1. These bunkers serve as a key element in the coal supply chain, ensuring the material remains dry and accessible, 2. Their strategic design is crucial for efficient operations in power plants, factories, and other facilities relying on coal. 3. Built to withstand environmental challenges, these structures typically incorporate features to prevent fire hazards and mitigate dust pollution. 4. The importance of proper storage cannot be understated, as it significantly affects coal’s quality and reactivity.

1. UNDERSTANDING COAL STORAGE BUNKERS

Coal storage bunkers are essential components in the energy and industrial sectors. They are specifically designed to store coal safely and effectively, ensuring that the coal remains in optimal condition until it is needed. The design of these bunkers is dictated by numerous factors, including the quantity of coal being stored, local environmental regulations, and logistical considerations.

In many operations, the bunker serves as the first line of defense against the elements. Coal can suffer from degradation if left exposed to moisture, temperature fluctuations, or other environmental factors. Efficient bunkering strategies not only prolong the life of the coal but also enhance its performance when used as a fuel source. Additionally, well-constructed coal storage bunkers help minimize waste and operational inefficiencies within energy generation or industrial processes.

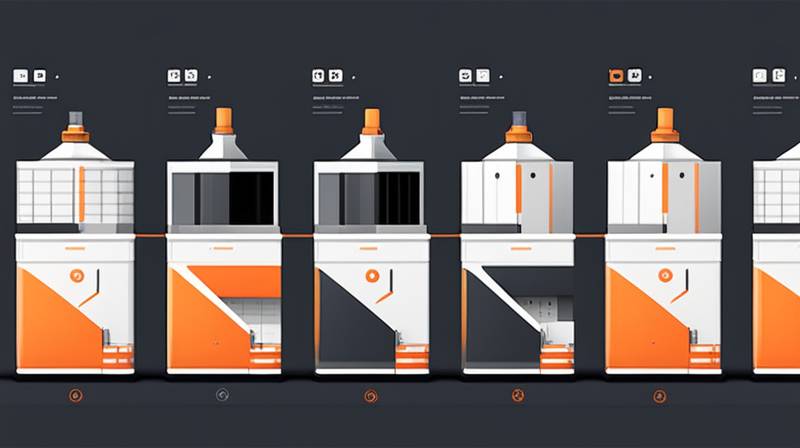

2. DESIGN AND STRUCTURAL ELEMENTS

The structural design of coal storage bunkers is integral to their functionality. Typically composed of reinforced concrete, steel, or a combination, these materials ensure durability and resistance against physical and chemical stresses. Designers take extra care in determining the appropriate layout, often employing a wedge or dome shape to permit efficient coal flow and minimize stockpiling issues.

Another critical aspect of coal bunker design is moisture control. Many facilities opt for sloped roofs or weatherproof coverings to prevent rain or snow accumulation on stored coal. Proper drainage systems must also be integrated into the structure’s layout to remove accumulated water. Ventilation is another important design consideration; effective airflow reduces the likelihood of spontaneous combustion and helps manage dust issues associated with coal storage.

3. OPERATIONAL SIGNIFICANCE

The operational significance of coal storage bunkers cannot be overlooked. These structures play a vital role in maintaining a consistent and reliable supply of coal to energy plants and industrial facilities. A well-functioning bunker system ensures that coal can be drawn as needed, reducing downtime and optimizing production processes.

Moreover, bunkers facilitate the effective handling of bulk quantities of coal. Automated systems can be integrated, allowing for efficient loading and unloading without compromising the integrity of the material. This technology is crucial in avoiding delays and minimizing manual labor, thereby improving overall safety and efficiency.

4. ENVIRONMENTAL CONSIDERATIONS

As concerns about coal mining and utilization grow, the environmental impact of coal storage is becoming increasingly significant. Bunker systems are often required to comply with stringent environmental regulations to minimize pollution and hazards associated with coal dust and other byproducts. Effective dust suppression systems are essential; these systems may include water sprays, dust collectors, and enclosed conveyance systems.

Additionally, managing potential fire hazards is crucial. Safety controls, such as temperature monitoring and regular inspections, are implemented to ensure that any signs of combustion are detected early. Designing coal storage bunkers with fire-resistant materials and incorporating fire suppression systems is also standard practice to ensure the safety of personnel and property.

5. ECONOMIC IMPLICATIONS

Effective coal storage solutions lead to significant economic benefits for organizations involved in coal energy production. By utilizing effective bunker systems, companies can reduce overall operational costs, manage supply chain logistics more fluidly, and mitigate losses associated with coal quality degradation. Ultimately, this improves the bottom line.

The capital investment in coal storage infrastructure can also yield long-term dividends. Well-structured storage facilitates the efficient use of coal as a resource, maximizing its economic potential. As facilities become better equipped for coal storage, they may also find opportunities for expansion, thereby increasing their market competitiveness and stability.

6. FUTURE TREND IN COAL STORAGE BUNKERS

As the energy landscape evolves, so too do the strategies and equipment employed for coal storage. Innovative solutions that emphasize sustainability, efficiency, and advanced technology are anticipated to dominate the market. This trend includes the adoption of smart technology, such as IoT devices, that monitor storage conditions and optimize coal handling systems.

Furthermore, as regulations surrounding coal usage grow stricter, facilities may start exploring alternative energy storage options or hybrid models that integrate renewable resources alongside coal. Bunker designs may evolve in ways that accommodate multiple fuel sources, enhancing adaptability and long-term sustainability. Adaptation and continuous improvement will be integral to the coal storage sector’s future landscape.

7. MAINTENANCE AND INSPECTION

Maintenance practices are crucial for the longevity and efficacy of coal storage bunkers. Regular inspections should cover structural integrity, functionality of safety systems, and accuracy in moisture control, among other factors. Identifying and addressing potential issues early can help prevent catastrophic failures and ensure efficient operation.

Additionally, maintenance strategies must include provisions for cleaning and dust management. Accumulated dust not only poses safety risks but can also interfere with the quality of coal stored. Implementing a proactive maintenance schedule can help mitigate these risks, maintaining the storage environment and enhancing overall productivity.

8. TRAINING AND CREW REQUIREMENTS

Personnel training is vital in ensuring the safe and effective operation of coal storage bunkers. The complexity of handling coal and the potential hazards associated with storage necessitate a well-trained workforce. Organizations should invest in comprehensive training programs that cover everything from safety protocols to operational procedures.

Moreover, familiarity with technological tools is increasingly important. As automation and advanced monitoring systems become commonplace, employees must possess the knowledge and skills to operate these systems effectively. Ongoing education and refresher courses can help maintain high standards and ensure that staff remains adept in their roles.

FAQs

WHAT MATERIALS ARE USED IN COAL STORAGE BUNKERS?

Coal storage bunkers are commonly constructed from robust materials such as reinforced concrete and steel which offer durability and resilience. These materials are essential for withstanding the stress of heavy coal loads, as well as environmental factors like moisture and temperature fluctuations. Choosing appropriate materials is critical for ensuring the long-term reliability and efficiency of the structure.

When selecting materials, factors such as coal weight, potential exposure to elements, and regional climate considerations must be taken into account. In many cases, a combination of materials may be employed; for example, reinforced concrete can provide a solid foundation while steel framing supports various structural elements. This combination maximizes both strength and flexibility, allowing for the successful implementation of innovative design features aimed at enhancing accessibility and safety.

HOW DOES COAL DEGRADATION AFFECT STORAGE BUNKERS?

Coal degradation can result from various environmental factors, including exposure to moisture, temperature variations, and even microbial activity. Such degradation can lead to several adverse effects, including reduced energy output, increased emissions, and a decrease in the value of the coal product.

Coal that has degraded or petrified may develop a hardened outer crust while losing cohesion on the inside, resulting in difficulties during the loading process. This can lead to inefficient fuel processing and may require additional handling measures. Ensuring optimal storage conditions—through effective bunker design and moisture management—can mitigate degradation risks and enhance coal quality over time.

WHAT ARE THE ENVIRONMENTAL IMPACTS OF COAL STORAGE?

Coal storage facilities pose several environmental challenges, primarily related to dust emissions and the risk of water contamination. Dust generated from coal handling can adversely affect local air quality, leading to health concerns for nearby communities and employees. As a result, stringent regulations govern how coal must be stored to minimize dust production.

Another significant concern is the possibility of leachate or runoff from coal storage areas contaminating local water sources. Hazardous chemicals in coal can enter waterways, harming aquatic ecosystems and posing health risks to humans. To combat these risks, modern coal storage designs often incorporate dust control systems and environmentally-friendly drainage solutions, helping facilities meet regulatory requirements while protecting the environment.

In summary, coal storage bunkers represent essential infrastructure for energy production and demand a comprehensive understanding of their design, operation, and implications for safety and the environment. Strengthening knowledge around coal storage will not just enhance the efficacy and reliability of coal as an energy source but will also contribute positively to safety practices and environmental stewardship. By addressing the needs for durability, moisture management, and safe operational practices, facilities can ensure that these critical structures continue to function reliably in ever-evolving energy markets. The interplay of economic, environmental, and operational priorities surrounding coal storage bunkers will shape their design and functionality in the future, making ongoing education and adaptation essential.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-a-coal-storage-bunker/