1. A variety of adhesives can effectively seal the solar lampshade, including, but not limited to, silicone sealant, epoxy resin, and polyurethane adhesive. Among these options, silicone sealant stands out due to its high flexibility, waterproof nature, and resistance to UV light. Its characteristics make it particularly suitable for outdoor applications where exposure to the elements is inevitable. Silicone sealant effectively accommodates thermal expansion in solar lamps and provides long-lasting bonds even in changing weather conditions, ensuring the longevity and functionality of the lampshade.

1. UNDERSTANDING SOLAR LAMPSHADE CONSTRUCTION

Solar lamps, an increasingly popular feature in modern landscaping, utilize a combination of components designed for functionality and aesthetics. The lampshade plays a critical role in protecting the solar panel and lighting mechanism from environmental factors such as rain, wind, and dust. Material selection for the lampshade is essential to ensure that it not only transmits light effectively but also withstands weather-related wear and tear.

The primary materials used in solar lampshades typically include durable plastics, tempered glass, or polycarbonate sheeting. While each of these materials has its advantages, they may lose their structural integrity over time if not properly sealed. Preventing water ingress is vital to maintaining the efficiency and lifespan of the embedded solar technology. Without proper sealing, the internal components can become damaged, leading to costly replacements or repairs.

2. TYPES OF ADHESIVES USED

In the realm of sealing solar lampshades, several types of adhesives are prominent. Silicone sealant, epoxy resin, and polyurethane adhesive each possess unique properties and applications. Choosing the right adhesive depends largely on the specific requirements of the solar lamp, including exposure conditions, materials used, and the desired longevity of the bond.

Silicone sealants, for example, are known for their versatility and ease of application. They remain flexible even after curing, which is essential for outdoor applications where materials may expand or contract in response to temperature variations. Additionally, their excellent water resistance makes them ideal for sealing solar lamps that are continually exposed to moisture. When applying silicone sealant, surface preparation is crucial; surfaces should be clean, dry, and free from contaminants to ensure an optimal bond.

Conversely, epoxy resin offers superior strength and durability, making it suitable for more demanding applications. The two-part system consists of a resin and a hardener, which, when mixed together, create a robust bond. Epoxy resin is less flexible than silicone sealant but can provide rigorous protection against moisture and extreme temperatures. It is essential to note that while epoxy can create a strong seal, the application process is slightly more complex, requiring precise measurements and mixing.

Polyurethane adhesive, another option, has gained attention due to its exceptional bonding capabilities on various materials, including plastics and metals. Its durability and resistance to environmental factors make it a robust choice for solar lamps. Polyurethane forms a strong bond and remains flexible once cured, accommodating material movement while ensuring a high resistance to water and weather conditions.

3. PROPERTIES OF IDEAL ADHESIVES FOR SOLAR LAMPSHADE

The effectiveness of an adhesive in sealing solar lampshades can be evaluated based on several key characteristics. Water resistance, UV stability, thermal flexibility, and ease of application are among the primary considerations. Each property contributes to the longevity of the lampshade and the effectiveness of the solar lighting system.

Water resistance is perhaps the most critical characteristic, as the primary function of sealing is to protect internal components from moisture intrusion. An adhesive that can withstand exposure to water without breaking down is necessary to avoid damage to sensitive electronics. Solar lamps often endure varied weather patterns, including heavy rain and humidity; thus, the adhesive must also resist degradation over time.

Another essential property, UV stability, ensures that the adhesive does not degrade when exposed to sunlight. Some adhesives can weaken or discolor over time when continually subjected to UV rays, compromising the effectiveness of the seal. Therefore, selecting an adhesive explicitly formulated to resist UV degradation will contribute to the longer-term effectiveness of the solar lamps.

Thermal flexibility allows the adhesive to endure temperature fluctuations without losing its integrity. As environmental conditions change, materials may expand and contract. Adhesives that maintain flexibility during these shifts can better accommodate such changes, ensuring that the seal remains intact.

Finally, ease of application is paramount for both manufacturers and DIY enthusiasts. Adhesives that can be easily dispensed, allow precise placement, and cure quickly can significantly enhance the user experience. Products that come in user-friendly packaging with clear instructions will attract more users, simplifying the sealing process.

4. APPLICATION TECHNIQUES FOR SEALING

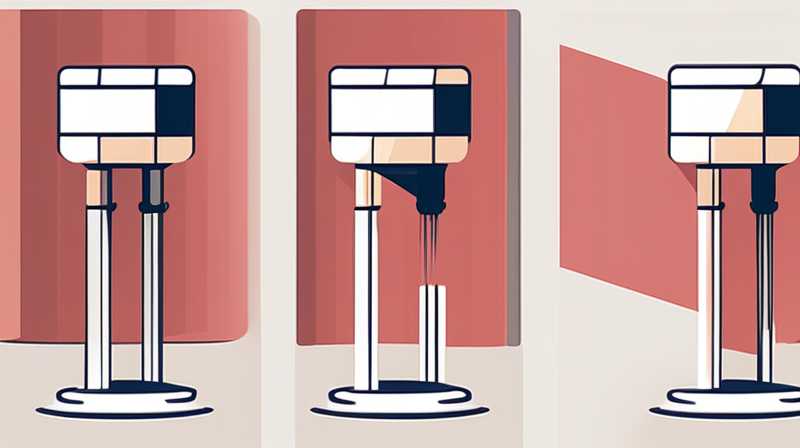

Proper application techniques are critical to achieving an effective seal for solar lampshades. Surface preparation, adhesive application, and curing time are essential steps that should not be overlooked. Each phase contributes to the overall success of the adhesion process.

Before applying any adhesive, it is crucial to prepare the surfaces thoroughly. This process involves cleaning the materials to remove dirt, grease, and any previous sealants that could hinder adhesion. Depending on the nature of the materials, surfaces may require sanding to create a rough texture, promoting a better bond. The importance of this phase cannot be overstated, as failure to achieve appropriately prepared surfaces can lead to sealant failure.

Once preparation is complete, careful application of the adhesive is necessary. For silicone sealants, using a caulking gun allows for a steady, controlled bead, which minimizes mess and maximizes effectiveness. It is advisable to apply an even layer, avoiding gaps that could permit water entry. With epoxy, meticulous mixing of the resin and hardener is essential before applying it to the desired areas, following manufacturer instructions for optimal performance.

Curing time is another critical consideration. While some adhesives may claim quick curing times, allowing for sufficient time for the adhesive to set according to guidelines is vital for achieving the desired strength. Rushing this process can lead to weak seals that may fail prematurely, resulting in damage and costly repairs.

5. COMMON MISTAKES TO AVOID

Several common pitfalls can occur during the sealing process of solar lampshades. Rushing the adhesive choice, inadequate surface preparation, applying improper amounts, and neglecting curing times are frequent errors that can lead to dissatisfaction and failures in the sealing function.

Selecting the wrong type of adhesive often leads to complications, such as inadequate sealing against moisture or loss of bond integrity under UV exposure. Users should carefully evaluate their options and select a product that meets the unique requirements of solar lamps. Taking the time to read product specifications and user reviews can help avoid bad choices.

Another common error arises in the surface preparation stage. If surfaces are not clean and free of debris, the effectiveness of the adhesive diminishes. Noting the specific requirements for different materials can help users avoid this mistake and lead to better adhesion results.

Applying too much or too little adhesive can adversely affect the seal’s effectiveness. Finding the right balance is crucial for ensuring longevity and quality protection. Users must follow application instructions provided by the adhesive manufacturers to guarantee the proper amount per surface area.

Lastly, users often overlook the required curing times, leading to premature exposure to elements before the seal has had sufficient time to set. This mistake can result in weak adhesion and water intrusion, thereby shortening the lifespan of the solar lamp.

FREQUENTLY ASKED QUESTIONS

WHAT IS THE MOST COMMON ADHESIVE FOR SOLAR LAMPSHADE SEALING?

Silicone sealant stands out as the most common adhesive used for sealing solar lampshades. Its flexible, water-resistant nature and tolerance to temperature fluctuations make it an excellent choice for outdoor applications. Manufacturers often prefer this option due to its ease of application and effective performance in protecting vulnerable components from the elements. Moreover, silicone sealants come in versatile forms, ranging from squeezable tubes to caulking gun cartridges, allowing users to select the most appropriate method for their needs.

The application process is straightforward; however, ensuring that surfaces are adequately prepared is critical for achieving strong adhesion. The silicone can accommodate material movement well, preventing the degradation often seen with more rigid adhesives in fluctuating temperatures.

While other adhesives, such as epoxy and polyurethane, also offer reliable sealing properties, they tend to have more specific applications and may require more attention in terms of preparation and curing time. Thus, silicone emerges as a favored choice among DIY enthusiasts and professionals alike for sealing solar lampshades efficiently and reliably in various environmental conditions.

HOW DOES WEATHER AFFECT THE SEALING MATERIAL OF SOLAR LAMPS?

The weather presents varying challenges that can significantly impact the sealing material of solar lamps. Rain, humidity, UV exposure, and temperature fluctuations are a few critical environmental factors that influence the integrity of the adhesive.

Water ingress is the primary concern for sealing materials. Adequate water resistance is essential to prevent moisture from damaging the internal components of solar lamps. Many adhesives, particularly silicone sealants, are formulated to provide superior moisture barrier properties, ensuring that the internal electronics remain protected even in heavy rain or high humidity.

UV exposure significantly affects the longevity of sealing materials, potentially leading to degradation over time. Sealants not specifically designed for UV resistance may weaken, become brittle, or discolor when subjected to prolonged sunlight, risking the overall sealing effectiveness. Choosing adhesives labeled as UV stabilized can help mitigate these concerns.

Temperature fluctuations also play a vital role, as some adhesives may lose flexibility and integrity when exposed to extreme heat or cold. Solar lampshade sealing materials should be capable of accommodating the expansion and contraction of materials caused by temperature changes. This adaptability ensures that the adhesive maintains a robust bond, even under extreme conditions.

In summary, while some sealants exhibit high resilience to weather variables, selecting the right adhesive based on conditions is the most efficient way to ensure the longevity and functionality of solar lamps.

HOW LONG DO ADHESIVES TYPICALLY LAST IN SOLAR LAMPS?

The longevity of adhesives utilized in solar lamps is influenced by various factors. Adhesive type, environmental exposure, installation quality, and maintenance practices all contribute to how long a seal lasts. On average, well-applied silicone sealants can remain effective for five to ten years, while other adhesives such as epoxy may provide even longer-lasting results, potentially exceeding ten years under ideal conditions.

Silicone sealants are favored for their flexibility and resistance to moisture, helping maintain a robust seal for several years, particularly if the solar lamps are subjected to moderate weather conditions. However, in harsher climates with extreme temperatures or persistent moisture, the lifespan of silicone may shorten.

Epoxy adhesives typically exhibit greater durability and can withstand environmental stresses more effectively than silicones. When properly applied, they can last well over a decade, making them suitable for demanding applications; however, the need for precise mixing and curing must be adhered to, as mistakes can compromise their performance.

Regular inspection and maintenance are vital components in maximizing the lifespan of adhesive seals. Users should periodically check for signs of wear, such as cracking or peeling, especially after harsh weather. Proactive maintenance can help identify issues before they escalate, allowing for timely repairs that can significantly extend the life of solar lamps.

Lasting Insights on Solar Lampshade Adhesives

The effective sealing of solar lampshades is critical for ensuring their longevity and functionality, as various adhesives, such as silicone sealant, epoxy resin, and polyurethane adhesives each bring unique properties that cater to specific needs. The adaptability of silicone sealant makes it the go-to choice for most applications, given its ease of use, waterproof capabilities, and resistance to UV light. Proper surface preparation, cautious application, consideration of environmental factors, and adherence to recommended curing times contribute significantly to creating a robust bond.

Moreover, understanding the longevity of different adhesives and their performance under various weather conditions can empower users to make informed choices. It is essential to avoid common mistakes during application, as these can lead to premature failures and costly repairs. Regular checking of seals for wear and damage can further enhance the effectiveness and lifespan of solar lamp systems.

In sum, when seeking adhesives to seal solar lampshades, careful selection and application processes are vital in preserving the functionality of these outdoor lighting solutions. By prioritizing appropriate adhesives and understanding their properties, users can successfully enhance the resiliency and reliability of their solar lamps against the natural elements, ensuring lasting brightness across diverse landscapes.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-glue-is-used-to-seal-the-solar-lampshade/