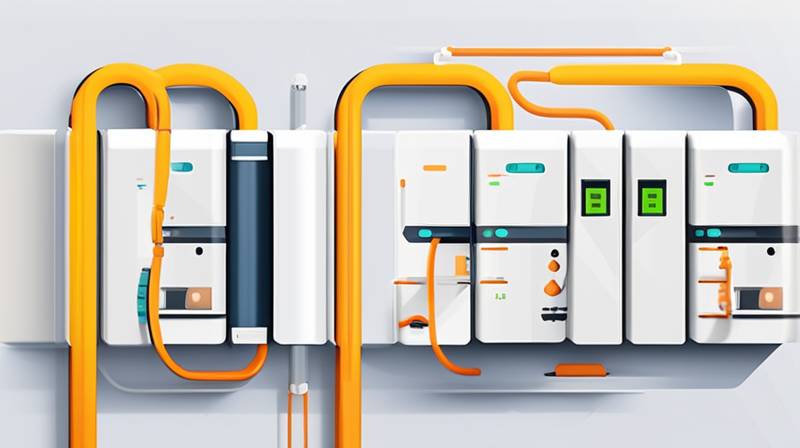

To effectively set up an energy storage system, specifically for solar energy utilization or other renewable sources, various types of cables must be utilized to ensure efficient energy transfer and system longevity. 1. Key cables include battery cables, which handle high current loads; 2. interconnect cables, that link batteries to inverters; 3. power cables, responsible for transmitting energy to the grid; 4. communication cables, which facilitate monitoring and management of the system.

Battery cables are crucial as they must be robust and able to manage significant electrical loads without overheating or losing efficiency. Typically made of thick copper, these cables often come with insulation suited for high-stress environments, thus safeguarding against short-circuits and energy loss. The gauge of the battery cable is directly linked to the amount of current it needs to carry and the distance it must cover; properly sizing these cables is essential to prevent any limitations on performance.

Interconnect cables also play a pivotal role in facilitating the flow of electricity from the energy storage unit to the inverter. These cables not only require durability but also the ability to handle fluctuations in voltage and current. They often come with advanced shielding to protect against electromagnetic interference (EMI), ensuring stable performance. The layout of the energy storage system and the distance between components factor prominently into the required specifications of these cables, highlighting the need for careful planning during installation.

Power cables, primarily used to direct energy from the inverter to the grid or load center, must comply with strict regulatory standards and guidelines for safety and efficiency. The selection of power cables often takes into consideration factors such as the system’s maximum current capacity, voltage rating, and environmental conditions. Proper insulation and shielding are also essential to minimize energy losses and potential hazards during operation. Compatibility with renewable energy infrastructure further emphasizes the importance of quality in power cable selection.

Communication cables are integral to the functionality of modern energy storage systems, particularly those employing smart technology features. These allow for real-time monitoring and management, giving users insights into energy consumption, system status, and performance analytics. The application of communication cables typically involves linking various components such as sensors, meters, and control systems. As technology advances, the requirements for these cables are consistently evolving, pushing the boundaries of what’s possible in energy management practices.

- BATTERY CABLES

Battery cables are specifically engineered to withstand high currents associated with energy storage systems. These cables are typically made from high-conductivity copper, allowing for minimal resistance and optimal performance. The gauge of the cable directly correlates with the ampacity; therefore, selecting the right size is crucial for ensuring safe operations. For instance, a 2 AWG cable might suffice for systems with lower power levels, but more demanding setups may require 1/0 AWG or larger. Insulation material is critical, as it must be rated for both temperature and environmental conditions. Common insulation types include PVC and cross-linked polyethylene (XLPE), each suited for particular settings and levels of flexibility.

Moreover, battery cables must also be designed to handle vibrations and physical stresses, especially in mobile installations. In stationary setups, consideration of corrosion protection is paramount, as the environment might expose cables to moisture or chemicals. Integrating different colors for positive and negative terminals can significantly enhance safety during installation and maintenance. Using high-quality connectors also impacts the longevity and overall effectiveness of the energy storage system, as these connections should securely fit and maintain contact with minimal resistance.

- INTERCONNECT CABLES

Interconnect cables serve as the vital link between multiple battery cells and the inverter within the energy storage system. These cables are specifically tailored to accommodate varying lengths and configurations of battery banks. A significant factor in selecting interconnect cables is their capacity to support the required voltage and current flow without incurring excessive energy losses. The overall layout of the battery bank will influence the selected gauge, and excessive lengths can lead to voltage drops, reducing efficiency.

Moreover, interconnect cables often incorporate features designed to combat external influences, such as EMI. Particularly in setups where multiple electronic devices are operational, EMI can disrupt performance, leading to inefficiencies. The employment of twisted pairs or shielding mechanisms can help in mitigating these issues. Establishing a clear organization of interconnect cables is equally critical, as a cluttered arrangement can lead to confusion during maintenance or troubleshooting, ultimately disrupting system functionality.

- POWER CABLES

Power cables are essential for transmitting electricity from the inverter to the point of use or back to the grid. Their selection is dictated by the specific electrical requirements of the energy storage system, including both current and voltage ratings. It is imperative that power cables comply with local and international standards to ensure safety and reliability. In particular, the National Electrical Code (NEC) provides guidelines that must be adhered to for installations within specific regions.

Power cables may need to be rated for outdoor conditions, especially if installed externally. Factors such as UV resistance and temperature fluctuations should influence the choice of cable insulation. Proper installation practices are essential to prevent wear and tear over time; utilizing proper conduit systems can protect against physical damages, while ensuring that the cables do not exceed their specified bending radius is vital for maintaining their operational integrity.

- COMMUNICATION CABLES

The rise of smart technology in energy management systems necessitates the use of communication cables, which facilitate data transfer between monitoring devices, control systems, and user interfaces. These cables vary in type, consisting of twisted pairs, coaxial, and fiber-optic options, each serving distinct functions and operational environments.

In many contemporary renewable energy systems, RS-485 or CAN bus protocols are commonly employed for communicating between various components. Selecting a communication protocol comes down to the specific performance requirements of the system, including data transfer speed and distance. Planning the network architecture is paramount in ensuring that data integrity is maintained across the system without data losses or delays. The insulation and construction of the communication cable should be capable of preventing interference from electrical noise, ensuring reliable interactions.

In a rapidly evolving field where energy efficiency and renewable integration are crucial, every aspect of an energy storage system, particularly the cabling, plays a vital role in its performance and reliability.

FREQUENTLY ASKED QUESTIONS

1. WHAT ARE THE CONSEQUENCES OF USING INCORRECT CABLES IN ENERGY STORAGE SYSTEMS?

Utilizing improper cables in energy storage systems can lead to several serious consequences. Firstly, overheating can occur if the cables are not rated for the electrical loads, potentially resulting in insulation breakdown and fire hazards. This overheating can also degrade the overall performance of the system, increasing energy losses and reducing operational efficiency. Secondly, using incorrect cable types may lead to increased voltage drops, resulting in lower output voltage reaching connected equipment. This can cause devices to underperform or fail to operate altogether. Additionally, mismanagement of electromagnetic interference (EMI) due to inappropriate cable selection can disrupt the communication between components such as inverters and controllers, leading to erroneous system data and ineffective monitoring. Furthermore, using a low gauge cable for a heavy-duty requirement can result in premature cable failure, requiring immediate replacement and incurring additional costs. Proper assessment and installation practices are crucial to avoid these pitfalls.

2. HOW DO I DETERMINE THE APPROPRIATE CABLE SIZES FOR MY ENERGY STORAGE SYSTEM?

Determining appropriate cable sizes for an energy storage system involves several key calculations and considerations. First, it is important to assess the total current that will flow through each cable during operation. Knowing the maximum current allows for the selection of a cable gauge that can handle the load without overheating. Gathering comprehensive data on the distance the currents will travel is also pivotal, as longer cable runs can lead to voltage drop. Voltage drop calculations should be made using the cable’s length, resistivity, and maximum current to ensure the selected cables will maintain an optimal operational voltage throughout the system. Moreover, consideration of the installation environment is essential; if cables will be exposed to various conditions, such as humidity or mechanical wear, selecting material with proper insulation is vital. Consulting relevant standards or codes, such as those provided by NEC or local regulations, also assists in ensuring compliance and safety in cable size decisions. Lastly, consulting with an experienced electrical professional can further guide and support the selection process based on the specific needs of the energy storage system.

3. HOW OFTEN SHOULD THE CABLES IN MY ENERGY STORAGE SYSTEM BE INSPECTED?

The frequency with which cables in an energy storage system should be inspected can often depend on various factors, including the operational conditions and the type of installation. Generally, a routine inspection should occur every six to twelve months to ensure that all cables, their connections, and associated components are free from signs of wear and damage. In cases of harsh environmental conditions such as extreme heat, moisture, or exposure to chemicals, more frequent checks may be warranted to quickly address any deterioration or failure signs. Inspections should focus on checking for abrasion, corrosion, or any discoloration of insulation, as these can indicate potential issues. Furthermore, visual examinations should include ensuring that all connections are secure and tight to prevent resistance, which can lead to overheating and inefficiencies. It is also worthwhile to establish a history of maintenance issues, as frequent need for repairs may suggest a more systemic problem that could require addressing. Establishing a proactive monitoring and maintenance schedule contributes significantly to the long-term viability of the energy storage system.

In summary, having the appropriate cables for an energy storage system is not just a technical requirement; it is a matter of ensuring performance, safety, and reliability. Selecting suitable cables for battery storage systems must involve careful consideration of specifications, requirements, and environmental factors. Ensuring adherence to regulatory standards and using high-quality materials further enhances the longevity and effectiveness of the entire system. All components, from battery to inverter connectivity, can significantly influence overall efficiency and operational capabilities. Moreover, implementing regular inspection schedules and adaptability to new technologies or upgrades allows for continuous improvement in energy management practices. Hence, engaging with knowledgeable professionals and prioritizing quality over cost will invariably yield a robust energy storage solution, paving the way for successful renewable energy utilization.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-cables-are-needed-for-energy-storage/